43

Hrs

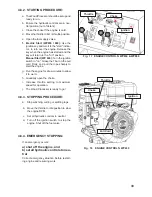

5.1.5 HYDRAULIC SYSTEM OIL FILTER & OIL CHANGE

1. Review the Operator's Manual for the Wood

Processor.

2. Move controls to neutral or off position, stop

engine, remove ignition key and wait for all

moving parts to stop before servicing, re-

pairing or maintaining.

3. Allow the machine to cool before changing

the oil. Hot oil can cause burns if it contacts

exposed skin. It is best to change oil while

the machine is warm to keep the contami-

nants in suspension.

4. Be sure to chock the wheels to prevent the

Wood Processor from moving while working

under the machine.

5.

Place a pan under the filter head.

6. Remove bottom hose and strainer (strainer

on WP830 / 860 only) to drain oil.

7. Allow the oil to drain.

8.

Remove hydraulic oil filter.

9. Apply a light coat of oil to the O ring and

install the replacement filter. Snug up by

hand and then tighten 1/2 turn.

10. Install and secure bottom hose and strainer.

11. Fill the reservoir with 26 L of Dexron III hydr-

raulic oil.

12. Run the machine for 1-2 minutes while op-

erating cylinder and check filter head for oil

leaks.

13.

If leaks are found around the filter, tighten

slightly. Repeat step 9.

14. Check hydraulic reservoir oil level. Top up

as required.

15. Dispose of the spilled oil in an approved

container.

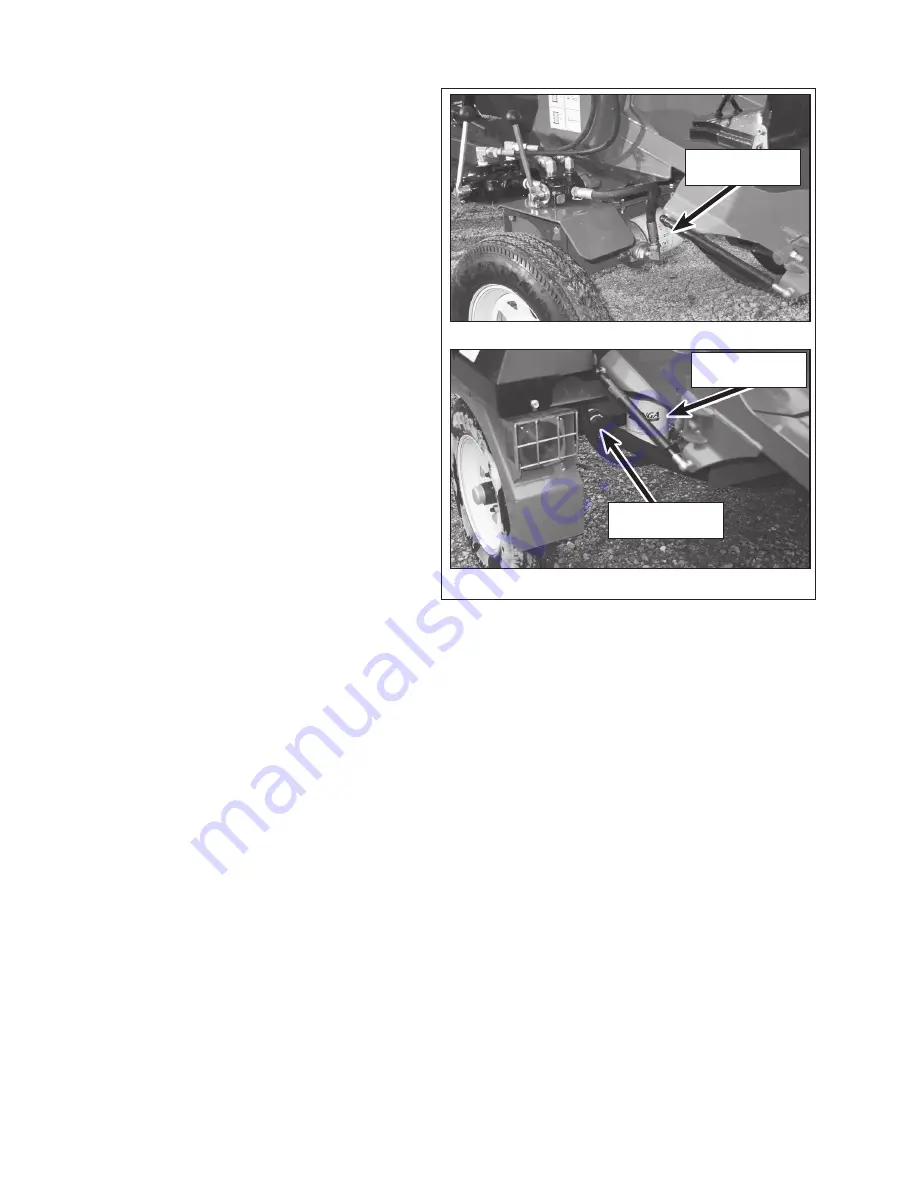

Fig. 27 HYDRAULIC SYSTEM FILTER

9.0 HP

14.0 HP

Hydraulic Oil

Filter

Hydraulic Oil

Filter

Strainer / Hose

Assembly

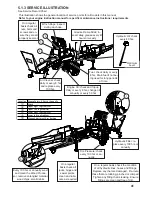

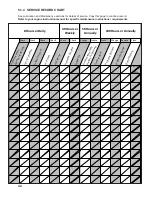

6 TROUBLE SHOOTING

The Wallenstein Trailer Woodsplitter uses hydraulic power to move a hydraulic cylinder rod to split wood

or logs. It is a simple and reliable system that requires minimal maintenance.

In the following chart, we have listed many of the problems, causes and solutions to the problems that

you may encounter.

If you encounter a problem that is difficult to solve, even after having read through this trouble shooting

section, please call your local dealer, distributor or Wallenstein. Before you call, please have this Opera-

tor's Manual and the serial number from your Woodsplitter ready.