44

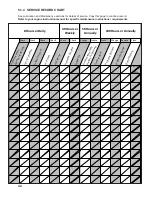

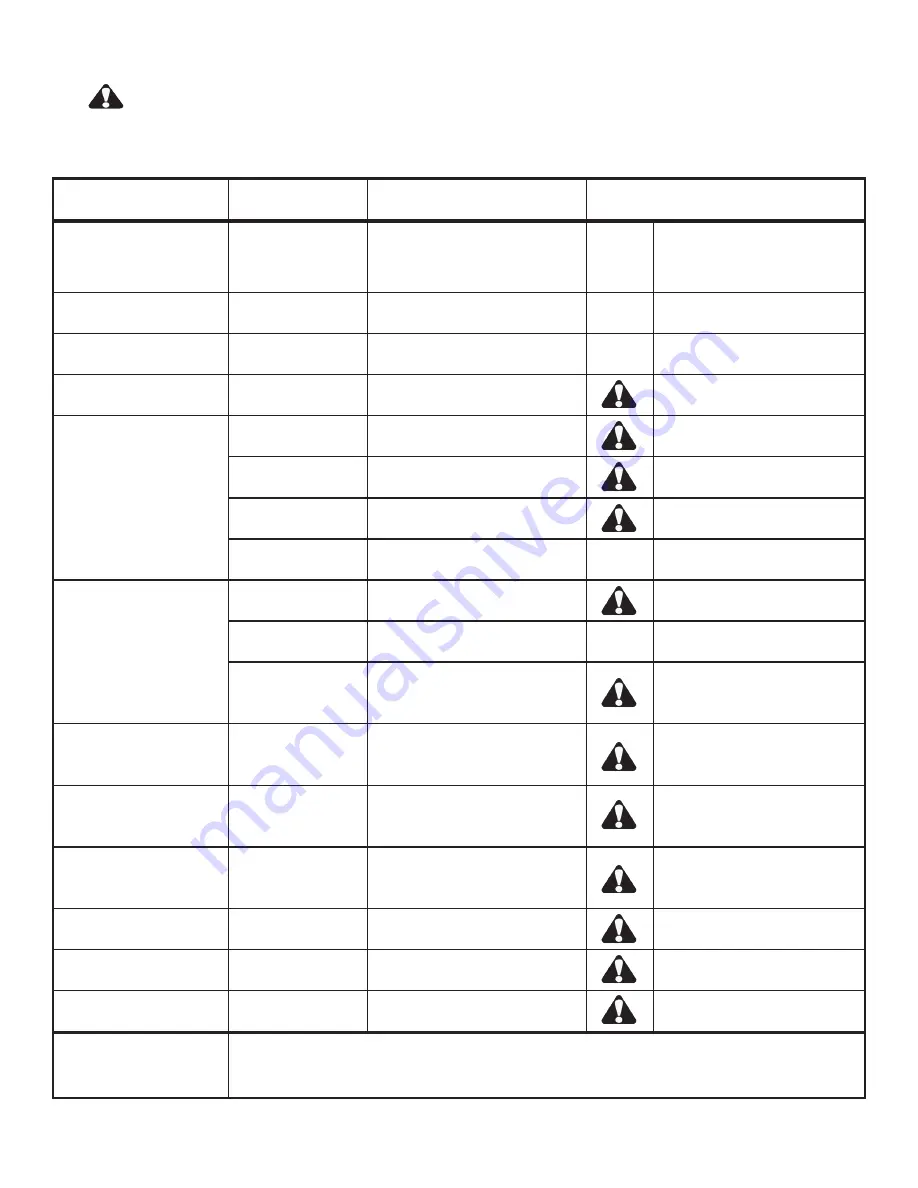

6.1 TROUBLE SHOOTING CHART

Always wear the appropriate safety gear when trouble shooting, performing maintenance or working around

the machine. This includes but is not limited to:

• Hard hat for protection to the head.

• Face mask for protection to the face and eyes.

• Heavy gloves for hand protection.

• Safety shoes with slip resistant soles and steel toes

Winch motor does not move Rope jammed

Disengage winch gears, pull rope

out and guide rope on to the spool

when retracting

Rope does not pull out

Winch gears engaged Disengage winch gears

Rope does not retract

Winch gears

disengaged

Engage winch gears

Cylinder rod moves slowly or

doesn't move.

Wood jammed around

wedge.

Shut machine off and safely remove

wood.

Ensure machine is off

No pressurized

hydraulic oil.

Oil filter plugged. Change filter.

Ensure machine is off and cooled

down.

No pressurized

hydraulic oil

Low hydraulic oil level, top up

Ensure machine is off and cooled

down

Not enough pressure.

Call technician, system relief setting

may be low.

Ensure machine is off and call

hydraulic technician.

Low engine speed.

Check that choke is off, check

throttle is set to maximum.

Detent set too tight.

Call technician, adjustment required

with detent on valve.

Ensure machine is off and call

hydraulic technician.

Hydraulic fluid too

cold.

Allow machine to warm up.

Hydraulic fluid is too

old or contaminated.

Change hydraulic fluid and filter

Ensure machine is off and cooled

down.

Control handle goes to

neutral before rod is fully

retracted.

Detent set too loose.

Call technician, adjustment required

with detent on valve.

Ensure machine is off and call

hydraulic technician.

Control handle doesn't go to

neutral when released.

Control may be

damaged.

Call technician, control may need

service or be replaced.

Ensure machine is off and call

hydraulic technician.

Cylinder stops on contact

with wood.

Second stage on pump

not functioning.

Call technician, pump may need

service or be replaced.

Ensure machine is off and call

hydraulic technician.

Wedge jumps.

Wedge frame

jamming.

Lubricate wedge frame wear plates.

Ensure machine is off.

Leaking hydraulic hose.

Hose worn or

damaged.

Replace hose.

Ensure machine is off and cooled

down.

Leaking cylinder.

Seals worn.

Call technician, seal replacement

may be required.

Ensure machine is off and call

hydraulic technician.

Engine related issues.

Control handle doesn't go to

neutral after rod is fully

retracted.

Cylinder rod / Winch motor

moves slowly or doesn't

move.

PROBLEM

CAUSE

SOLUTION

CAUTION

Refer to your engine instruction manual for specific trouble shooting instructions / requirements.