41

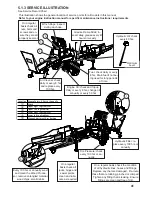

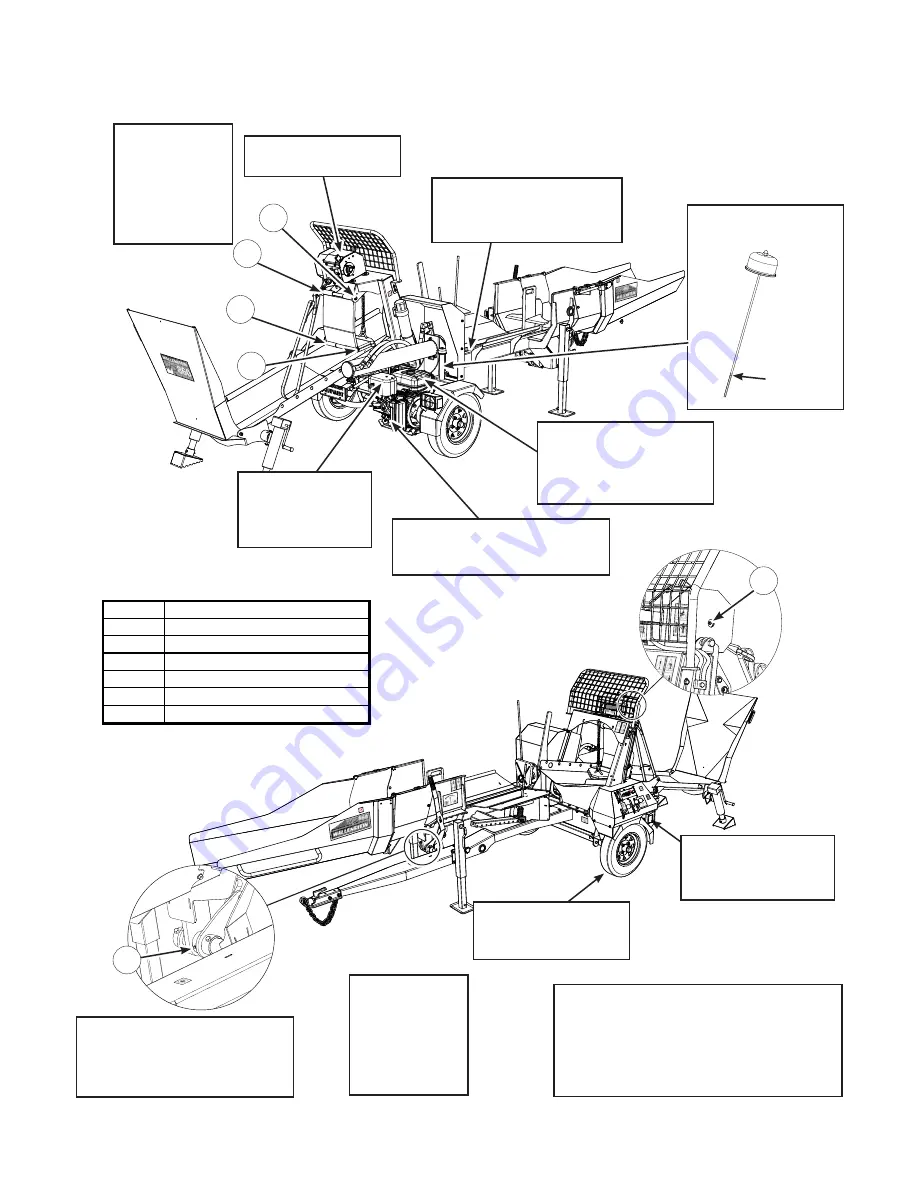

5.1.3 SERVICE ILLUSTRATION

See Service Record Chart

This illustration shows the general location of service points for all models in this manual.

Refer to your engine instruction manual for specific maintenance instructions / requirements

On a regular

basis check all

nuts, bolts and

screws and en-

sure they are all

properly secured

On a regular basis check the condition

of all hydraulic lines, hoses and fittings.

Replace any that are damaged. Re-route

those that are rubbing, pinched or crimped.

Tighten any fitting that is leaking. Ensure

fittings are clean and free of dirt.

Hydraulic Oil: check

every 40 hrs.

Location Grease Points - 50 hrs or Annually

Winch

Upper Right Log Stabilizer

Upper Left Log Stabilizer

Lower Right Log Stabilizer

Lower Left Log Stabilizer

Wedge Adjustment Arm Bushing

3

4

2

5

Optimum

Level

Hydraulic Filter: re-

place every 100 hrs or

annually

Every 100 hrs or annually. wash

and clean the Wood Proces-

sor, remove entangled material,

wood chips, small debris

1

6

Tire Pressure: check

every 100 hrs or an-

nually.

On a regular

basis check all

jacks, hinge and

swivel points,

clean and lubri-

cate as required

Air Cleaner: check

daily or every 8 hrs

and replace every

100 hrs.

Grease Frame Slide: in-

spect daily, grease every 40

hours or weekly

Fuel: check daily or every

8 hrs, Drain fuel if not be-

ing used for long periods

of time.

Engine Oil: check and top up

daily or every 8 hrs, change oil

annually or every 50 hrs

Winch Rope: inspect

during each use.