EmberGlo

A Division of Midco International Inc

8471 11

3

AR60 - Service

Service

Continued

Note: Before attempting service, unplug power cord. For service or examination, all “working parts”

of the steamer are exposed by removing fi rst the cabinet top, then the back. The wiring diagram and

spare clean out gasket is located on inside of back.

Electric Switch/Thermostat

The on-off switch should audibly “click” when operated manually. To determine if electrically opera-

tive, a continuity check should be made.

-

The thermostat is adjusted at the factory default setting. It is not recommended to re-adjust the

setting. If found defective it is recommended to replace.

Pump System

Operate pump lever and observe length of pump shaft travel. It should travel approximately 7/8″. If

travel is less, check for broken or disengaged pins, links, crank.

-

Disconnect brass fi tting at water riser tube and bend tube up slightly so discharging water will

clear front of unit. Operate pump lever; water should shoot out about 15 feet. If water does

not shoot out, remove and inspect inlet tube assembly for leaks. Any air entering tube will break

the suction on the water. Check installation and alignment of dip tube spring as detailed under

next section. If water still doesn’t not shoot out, pump should be replaced.

-

A strainer is located in the inlet tube at pump fi tting. Loosen fi tting and remove pump inlet tube.

Dump strainer out of tube and wash under running water, then replace.

Dip Tube and Spring

If the dip tube does not enter the water pan properly it must be replaced. When replacing, the open

end or point of hook must be at the bottom and the eye must be in a vertical plane, like a coin

standing on edge.

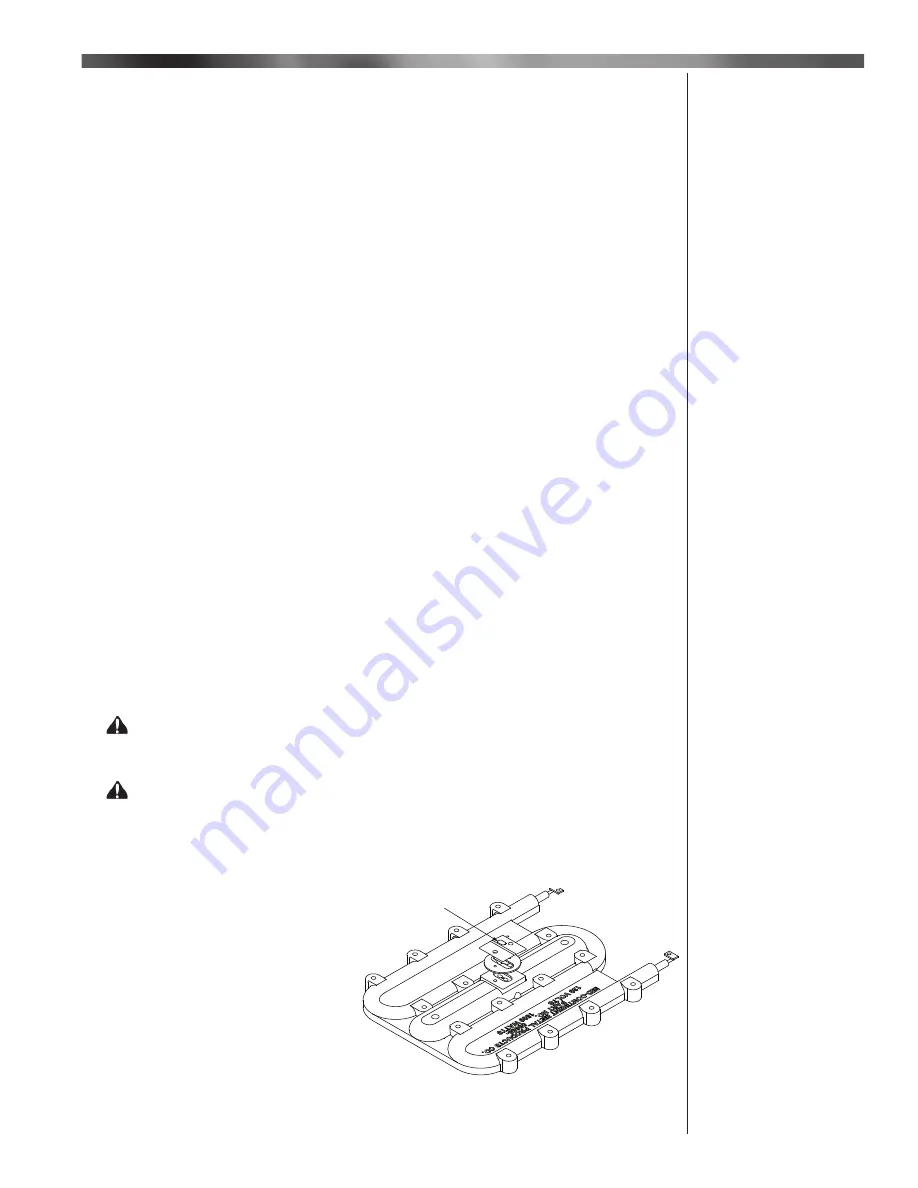

Steam Generator

1.

To Clean.

Remove cabinet top and generator insulation. This will expose a square plate on the

generator, which is removable for cleaning water passages.

-

Check the three exposed holes when the clean-out cover is removed. If any of these holes

are clogged, clean them out by hand-twisting a 7/64″ drill for the center hole and a 3/16″

drill for the two side holes.

-

After thoroughly cleaning the three holes, plug in power supply and operate lever to steam

unit.

THE UNIT MUST BE HOT.

Operate several times to blow out any accumulation.

-

Replace the clean out cover, using new gasket. With the unit hot, operate lever. The unit

should steam properly. If it does not, and the pump is operative as detailed under PUMP

SYSTEM, the entire generator assembly is probably limed and must be disassembled and

cleaned or replaced.

-

To clean generator assembly, separate casting from plate and clean lime from cavity

in casting.

Caution: Do not damage plate by scratching or polishing the fi nish.

2. Information on use of the overheat label (8451-98)

Caution: To prevent accidental shock, disconnect electrical plug from receptacle

before attempting service.

-

An overheat label is located on the clean-out cover of the steam generator. The triangle in

the center of the label, as shown below, is normally gold color. This triangle turns black at 450° F,

indicating that the generator has overheated at least once. The operating temperature of the

generator should be between 350° and

400° F. If it is not, the thermostat should be

replaced.

Note: the overheat label will not return

to its original gold color once it has turned

black. It should be scraped off and replaced

so that the thermostat can be monitored at

all times. In addition, in the event that the

thermostat has to be replaced, it is important

to replace the label immediately afterwards

so that someone at a later inspection will not

suspect a faulty thermostat.

450

232

C

F

CelsiDot

Overheat Label

Figure 2. Steam Generator Overheat Label Placement