2

EmberGlo

A Division of Midco International Inc

8471 65

E2436 - Installation and Maintenance

Daily Maintenance

Preventative

Maintenance

Installation

Wiring

: All units are shipped wired for single phase current.

Ventilation

: Do not install broiler closer than 5″ to the back or 8″ on the side walls.

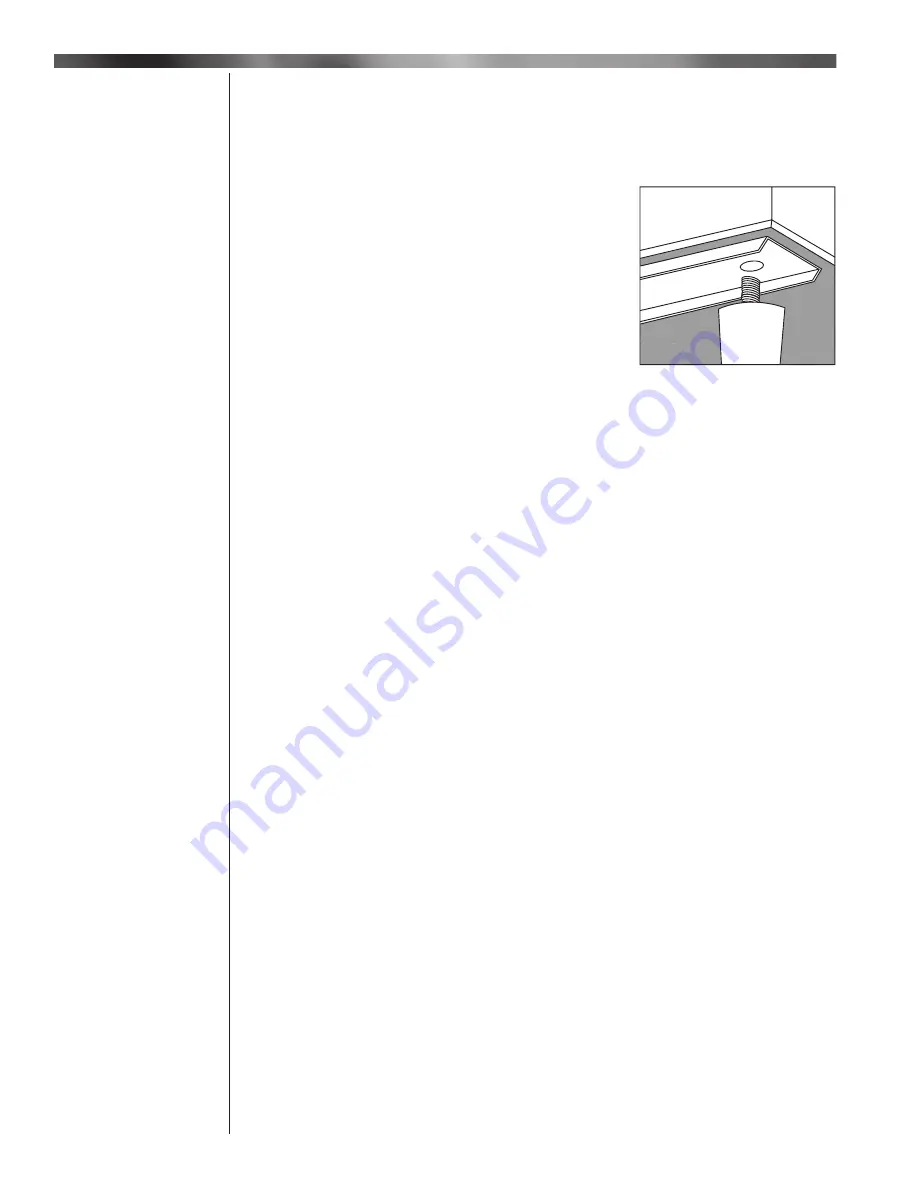

LEGS SHIPPED

WITH THE UNIT MUST BE INSTALLED WITH LEG CHANNELS.

Minimum leg height, with no

blockage around the bottom of the broiler, must be maintained for proper ventilation.

FAILURE TO INSTALL OR REMOVAL OF THE LEGS IS A VIOLATION OF THE APPROVAL

SEALS AND VOIDS THE MANUFACTURER’S WARRANTY.

- Remove the leg channels and knobs that are packed in the

broiler (located in the hopper front). The leg channels are two

long pieces of U-shaped steel designed to prevent warping of

the broiler frame when the broiler is moved by sliding on its legs.

See Figure 1

- Prop the broiler up and line up the holes in one of the leg

channels over the holes for the weld nuts on the front end of the

broiler.

- Screw two of the legs provided into the weld nuts to attach the

legs and hold the leg channel in place.

- Repeat procedure for the rear legs.

Figure 1 - Leg Placement

Turn the dial to “HI” and preheat for 20 minutes. Dial down to achieve desired cooking temperature.

______________________________________________

NOTE: Always clean the unit starting at the top and working down. Be sure that the grease hopper

and grease pan are in place before you proceed with any cleaning procedure in order to prevent any

scrapping or grease from dropping into the base and onto electrical wiring and terminal blocks.

- With normal use of the broiler, deposits build up on the top and bottom of the grate. In order to

assure safe operation, these deposits must be cleaned periodically during the day from both the top

and underside of the grill or grate casting.

a. To clear the top of the casting, scrape each groove with the tip of the scraper provided

until the surfaces are clear.

b. To clear the underside of the casting, insert the scraper head through the slots of the

grill and turn the scraper handle parallel to the grooves. Pulling upward, scrape

deposits from the grill underside. Repeat for each groove.

c. Empty grease pan periodically to avoid messy overfl ow.

______________________________________________

- When broiling is fi nished for the day clean as follows:

a. Clean deposits from the top and bottom of the grate as explained above.

b. Empty the hopper, clean and reinsert hopper.

c. Turn unit to “HI” and leave on for approximately 20 minutes. This will char the

remaining grease on the grill casting.

d. Turn off controls. When grill is cool, scrape the underside again and wire brush the

surface to complete cleaning of the grill.

e. Remove and clean the side splash guards and rear trough. Wash the front and rear

wells and wipe along the sides.

f. Wipe the casting with a dry clean cloth -- do not use water or detergent on the castings.

g. Empty and clean the grease pan.

______________________________________________

FRONT OF BROILER

LEG CHANNEL

LEG