EmberGlo

A Division of Midco International Inc

MADE

in the

USA

4

ES10 Steamer Maintenance - Daily and When Required

DANGER: Use extreme caution when adjusting timers. Bare wire terminals and/or bare

wires are exposed. Unplug male twist-lock plug or use extreme caution if steamer is plugged

in when making timer adjustments. Use an insulated or fi berglass screw driver.

IMPORTANT: KEEP LID CLOSED WHEN NOT IN USE.

This keeps the food pan hot and reduces

condensation in the steam chamber. When steamer is fi rst installed, or when reconnecting water

hose, operate

STEAM

button several times to purge air from lines.

____________________________________

Maintenance

Food Pan and Grid

on all models should be removed and washed with a detergent or run through

a dishwasher.

WARNING: Under no circumstances should the entire Steamer be run through a

dishwasher. If any of the switches or timers in electric control compartment get wet they can

malfunction. Never try to use a device that has been wet—replace it.

All exposed stainless steel surfaces should be wiped with a damp cloth or cleaned with a chlorine

free stainless steel cleaner. Rust spots can develop on stainless steel surfaces that are not cleaned

daily.

____________________________________

Generator:

The cavity in the generator casting may accumulate lime and can be cleaned by

scraping or wire brushing. Do not remove all of this deposit since a thin coating improves steaming.

Water Nozzles:

The water nozzles may be pulled out for cleaning. Clean small holes and inside of

nozzle tube. Located in the nozzle tube is a tool to be used for cleaning the holes in the water tube.

Water Inlet:

If the nozzle socket tube through the generator is limed, remove plug at bottom and

push lime out with a wire or small rod.

Strainers:

To wash strainer located in hose; fi rst, remove hose from steamer. Remove quick

connect fi tting from hose. Run water through hose in reverse direction. Return to original

connections.

There is a strainer in inlet of solenoid valve that normally does not require cleaning but under

extreme conditions may have to be removed and cleaned.

____________________________________

Maintenance

Daily

Maintenance

As Required

Operation Continued

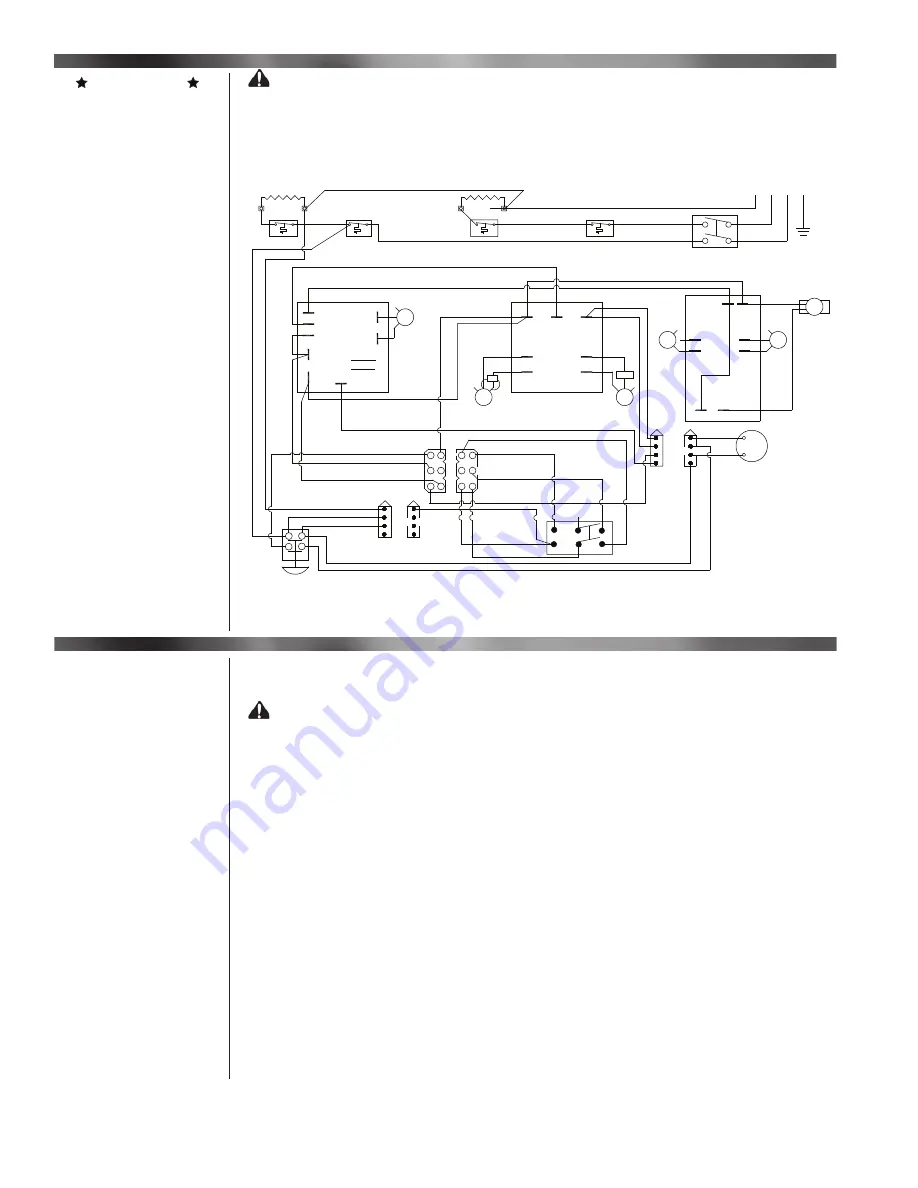

Do not connect to a circuit operating

at more than 150 Volts to ground

Input

208V/240V/60 Hz

Neutral

Power

Switch

BK

Thermal Cut-off

BR

BK

BK

R/BK

W

BK

W

Heating

Element

1600W

Thermostat

120V

120V

GND

4

2

5

1

Buzzer

1425-00

Buzzer

Duration

2528-10

Hot

Neut

2

3

Y

1M

BL

BL

2528-00

Buzzer

Delay

Y

Water

Solenoid

Valve

8402-26

7

6

Ext

Res

BL

Buzzer Timer

8406-63

1

4

COM NO

BL/W

1

2

3

4

1

2

3

4

1M

2528-20

Wiring for ES10 Steamer

with 101 or 102 control

OR

OR

610K

1M

BL/W

BR

BR

9

8

Ext Res

BR

3

2

1

Neut

Hot

Load

Shot Timer

On

Time

Off

Time

BL/W

BL/W

22K

100K

Y

NC

NO

COM

HOT

Neut

1

8

9

2

3

6

7

5

Ext Res

Cycle

Timer

1M

2528-40

Cycle

Time

SW

8406-64

W

BK

OR/BK

2528-30

R

W

R/BK

BL

BK

W

R/BK

W

R

BL

BL

1

2

3

4

1

2

3

4

3

6

6

3

2

5

5

2

1

4

4

1

OR/BK

3

4

2

1

Steam

Button

R

BK

BK

Thermostat

Heating

Element

1600W

BK

Thermal

Cut-Off

R

R

Y

8406-62

Manual

Cycle

8423-35

6

Figure 2: Wiring Diagram