1

Power Supplies

1-13

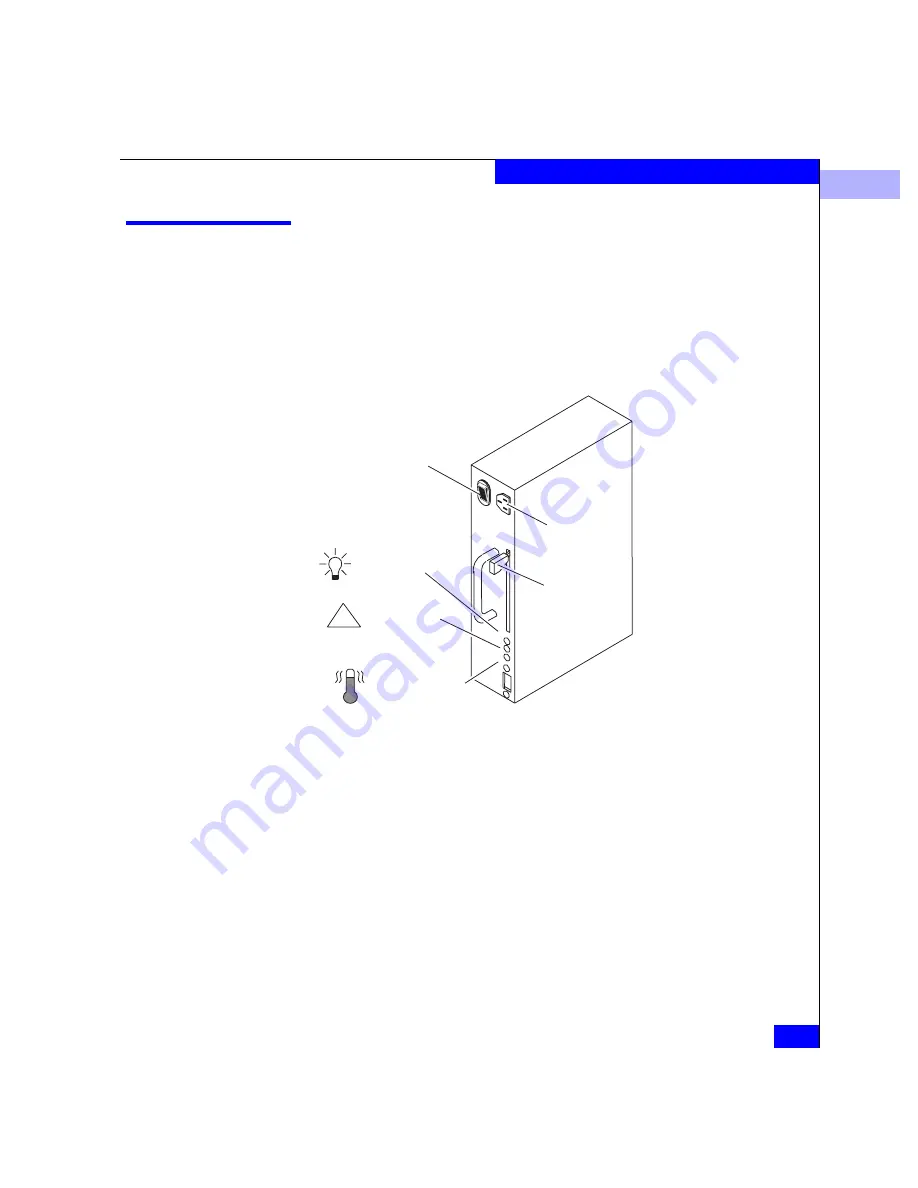

About the Deskside Disk-Array Processor Enclosure

Power Supplies

The four power supplies are located behind the drive fan pack. Each

power supply is an auto-ranging, power-factor-corrected,

multi-output, off-line converter with its own line cord and on/off

switch. The figure below shows DAE and DPE power supplies. The

DPE power supply is similar to the DAE power supply, differing in

depth (30% deeper), due to the higher power requirements of the

DPE.

Figure 1-10

Power Supply Controls and Indicators

Each supply supports a fully configured DPE/DAE and shares

current with the other “like” supply if one is present. The drive and

LCC voltage lines have individual soft-start switches with

short-circuit current-limit capability. The soft-start switches protect

the disk drives and LCCs if you install them while the deskside DPE

is powered up. A CRU with power-related faults will not adversely

affect the operation of any other CRU.

ON/OFF switch/breaker

Latch

Active light

(green)

ac inlet

Check light

(amber)

!

Cooling Check

light (amber)