General Manual Electric Winches with UMPH rope-English Rev.1.1 – 10-12-2014

Installation of gear units classified under Directive 94/9/EC

Category 2D gear units must be installed in compliance with the provisions of standards EN

1127-1 and EN 50281-1-2. The installer must, therefore, be fully informed and trained for this

application.

The installation technician must be aware of the ATEX class of the installation area, as well

as the risks associated with the presence of a potentially explosive atmosphere, with

particular attention to explosion and fire hazards, and thereby adopt the necessary safety

precautions.

All maintenance, assembly and disassembly work must be done

outside the explosion ha-

zard area

by trained personnel.

Check that all accessory components (cables, joints, cable glands, cooling units, etc.) comply

with the Essential Health and Safety Requirements of the ATEX directives. Handle them with

extreme care to avoid altering their characteristics.

Clean the gear unit thoroughly after installation.

4.2 GEARBOX LUBRICATION

Check the winch datasheet (annex 1) for the type of oil used for your winch.

EMCÉ winches are usually delivered with lubricating oil. Nevertheless check oil level at

installation and fill up if necessary. For further details see section (7).

Lubricating oil temperature shall never exceed 100 °C.

4.3 ROPE

4.3.1 Fitting the fiber rope to the winch drum

Before fitting the rope the cable anchor on the drum should be positioned to an

easily accessible position. During fitting of the rope the winch must be isolated from

the main supply.

On winches with a pressure roller the spring tensions must be removed before and

during the installation of the rope.

Changing the winch rotation by reversing the wire dead end connection is only possible when the winch is

equipped with two wedge pockets or two cable clamp mounting positions.

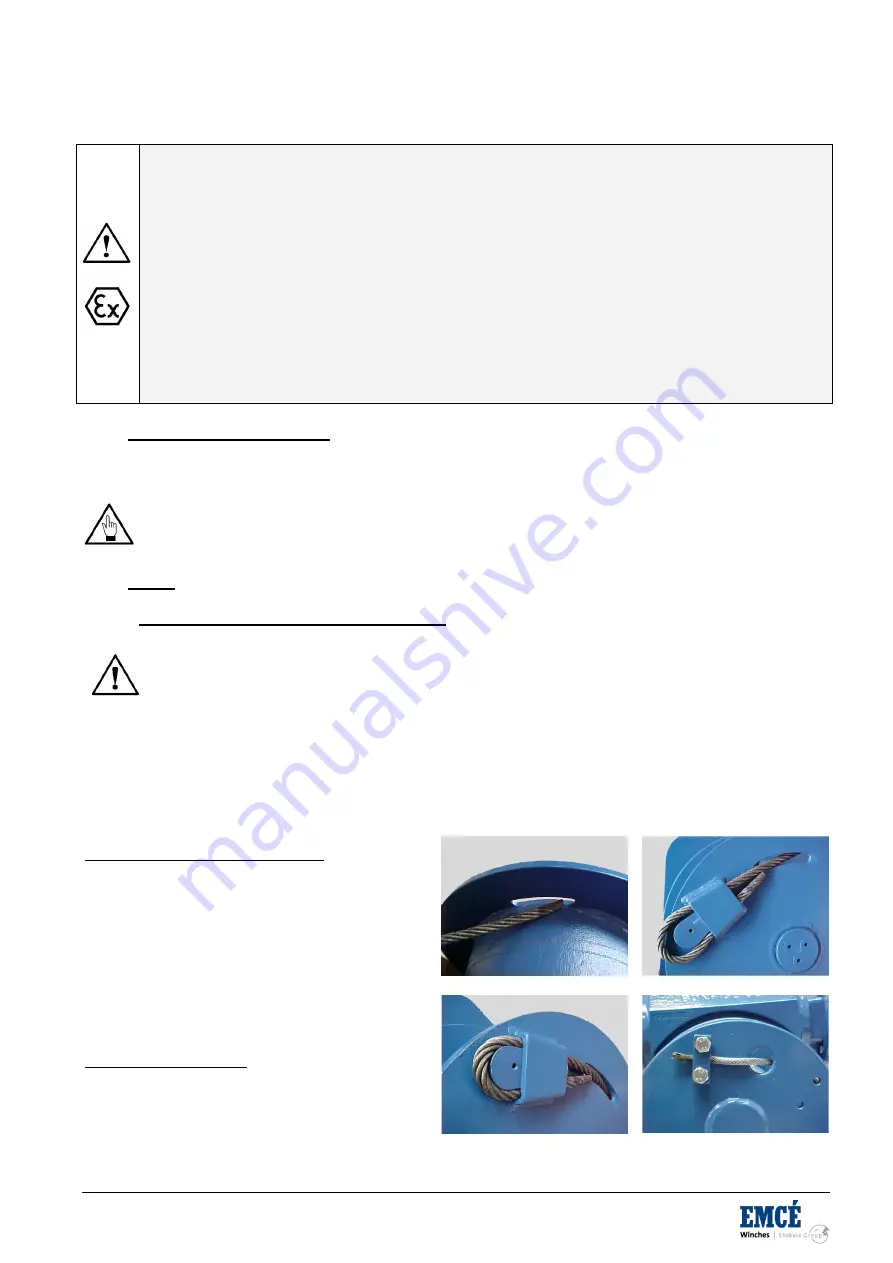

Fit wire dead end from the inside of the drum to the outside through the slotted hole in one of the drum flanges

(see picture 4.3.1)

Fastening with pocket and wedge

The wire dead end shall be fitted in the pocked as

to make an eye around the wire wedge with free

end fitted backwards through the pocket (see

picture 4.3.2).

Pull the wire from the opposite side to press wire

and wedge into the pocket (see picture 4.3.3). The

free end of the wire end shall at al times be 5

times the rope diameter and the rope end shall be

prevented from fraying.

Fitting with wire clamp

Fit the wire as shown on picture 1 and through the

wire clamp on the drum flange.

Tighten wire clamp bolts according to the table in

section 4.1(see picture 4.3.4).

Picture 4.3.1

Picture 4.3.2

Picture 4.3.3

Picture 4.3.4

Summary of Contents for 1004156

Page 1: ...SR 30 E 1004156 Planetary Winches...

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ...3 x 4 0 0 V P E 5 0 H z 3 x 4 0 0 V P E 5 0 H z 3 x 4 0 0 V P E 5 0 H z...

Page 54: ...Manuf act urer Type Quant it y Descript ion Collector materiallist detail...

Page 55: ...Manuf act urer Type Quant it y Descript ion Collector materiallist detail...

Page 56: ...Manuf act urer Type Quant it y Descript ion Collector materiallist detail...

Page 57: ...Manuf act urer Type Comp Descript ion Quant it y Material Detail...

Page 58: ...Manuf act urer Type Comp Descript ion Quant it y Material Detail...

Page 59: ...Manuf act urer Type Comp Descript ion Quant it y Material Detail...

Page 60: ...Manuf act urer Type Comp Descript ion Quant it y Material Detail...

Page 61: ...Manuf act urer Type Comp Descript ion Quant it y Material Detail...

Page 62: ...Manuf act urer Type Comp Descript ion Quant it y Material Detail...

Page 65: ...General Manual Electric Winches with UMPH rope English Rev 1 1 10 12 2014 Notes...

Page 66: ...General Manual Electric Winches with UMPH rope English Rev 1 1 10 12 2014...