Technical Data 300-series gearboxes-English Rev.1.3 - 15-12-2010

INSTALLATION, USE AND SERVICE MANUAL 300-SERIES GEARBOXES

Use the gear unit only for the applications envisaged by the Manufacturer. Improper use can result in risks to

personal health and safety and economic damages.

Keep the gear unit at its maximum efficiency by following the routine maintenance schedule. Good

maintenance enables the unit to operate at maximum performance over a long service life in compliance with

safety regulations.

When working on the unit in areas which are difficult to access or hazardous, ensure that adequate safety

precautions have been taken for the operator and others in compliance with the provisions of law on health

and safety at work.

All maintenance, inspection and repairs must only be done by an expert maintenance technician fully familiar

with the attendant hazards. It is, therefore, essential to implement operating procedures which address

potential hazards and their prevention for the entire machine. The expert maintenance technician must

always work with extreme caution in full compliance with applicable safety standards.

During operation wear only the apparel and safety equipment indicated in the User instructions provided by

the Manufacturer or laid down by applicable laws on safety at work.

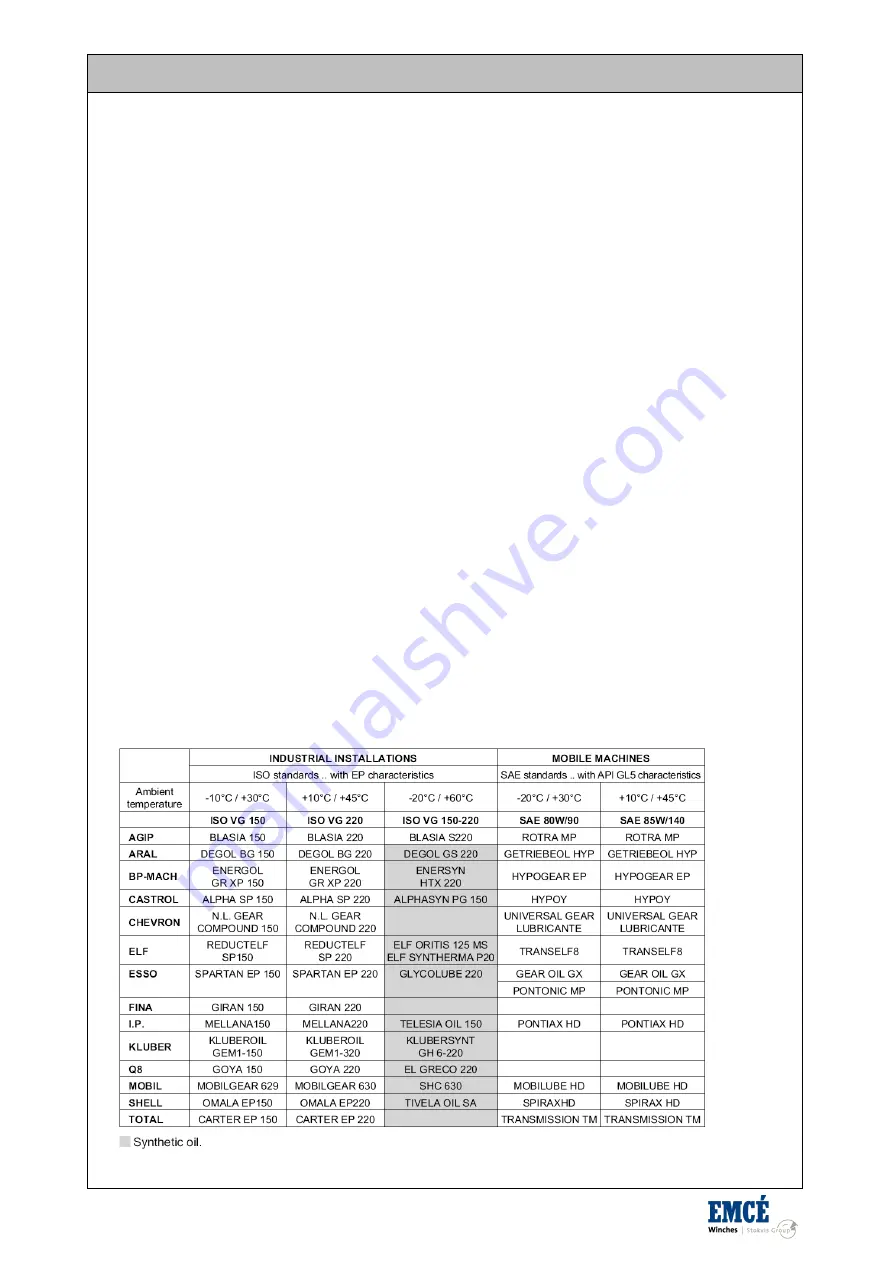

Replace worn components with original spare parts. Use the lubricants (oil and grease) recommended by the

Manufacturer.

Do not dump polluting materials into the environment. Dispose of all such materials as stipulated by

applicable legislation.

After replacing lubricants clean the gear unit’s surfaces and the walk-on surfaces around the work area.

4.0 STORAGE

Some recommendations for storing the gear unit are indicated below.

1.

Do not store the unit in excessively humid conditions or where it is exposed to the weather (do not store

outdoors).

2.

Do not place the gear unit directly on the ground.

3.

Place the gear unit on a stable base and make sure that it is not subjected to accidental displacement.

4.

Store the packaged gear unit (if allowed) in accordance with the instructions on the packaging itself.

If the gear unit is stored for more than 6 months, the following additional precautions must be taken:

5.

Cover all machined external surfaces with a rust roofing product such as Shell Ensis or equivalent product

with similar properties and application range.

6.

Fill the unit with lubricating oil and make sure the vent plug is positioned uppermost. Before putting the unit

into service, the oil used for storage must be drained and replaced with the correct quantity of recommended

operating lubricant.

5.0 LUBRICATION

Before putting the gear unit into service, check the oil level. This must be done with the gear unit in the mounting position

in which it will be used in the application. If necessary, if or top up the lubricant to the filling mark.

Summary of Contents for 1004156

Page 1: ...SR 30 E 1004156 Planetary Winches...

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ...3 x 4 0 0 V P E 5 0 H z 3 x 4 0 0 V P E 5 0 H z 3 x 4 0 0 V P E 5 0 H z...

Page 54: ...Manuf act urer Type Quant it y Descript ion Collector materiallist detail...

Page 55: ...Manuf act urer Type Quant it y Descript ion Collector materiallist detail...

Page 56: ...Manuf act urer Type Quant it y Descript ion Collector materiallist detail...

Page 57: ...Manuf act urer Type Comp Descript ion Quant it y Material Detail...

Page 58: ...Manuf act urer Type Comp Descript ion Quant it y Material Detail...

Page 59: ...Manuf act urer Type Comp Descript ion Quant it y Material Detail...

Page 60: ...Manuf act urer Type Comp Descript ion Quant it y Material Detail...

Page 61: ...Manuf act urer Type Comp Descript ion Quant it y Material Detail...

Page 62: ...Manuf act urer Type Comp Descript ion Quant it y Material Detail...

Page 65: ...General Manual Electric Winches with UMPH rope English Rev 1 1 10 12 2014 Notes...

Page 66: ...General Manual Electric Winches with UMPH rope English Rev 1 1 10 12 2014...