12

Discharge hose.

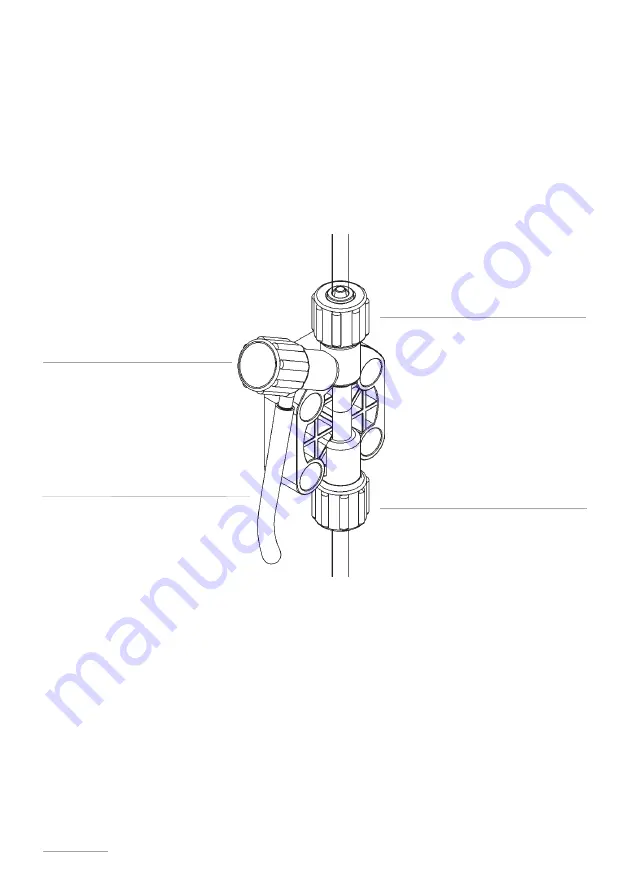

Insert one side of discharge hose into discharge connector as shown in fig (C).

Insert other side of discharge hose into product’s tank.

During priming procedure product exceeding will flow into tank.

For priming procedure see page 14.

fig (C)

Discharge hose

Discharge Knob

To Delivery hose

To Suction hose

Summary of Contents for VMS MF

Page 57: ...57...