168, 168H, and 68 Series

2

Specifications

maximum allowable pressures

Diaphragm

168 Series:

100 psi (6,90 bar)

168H Series:

150 psi (10,3 bar)

body:

See Table 1

operative Temperature limits

(1)

-10° to 150°F (-23° to 66°C)

port Diameter

3/32-inch (2,38 mm)

Flow Coefficients

c

g

:

7

representative c

1

:

35

pressure connections

1/4-inch NPT female

approximate Weights

68 Series:

0.5 pound (0,23 kg)

168 Series:

3 pounds (1,36 kg)

168H Series:

5 pounds (2,27 kg)

1. This term is defined in ISA Standard S51.1-1979.

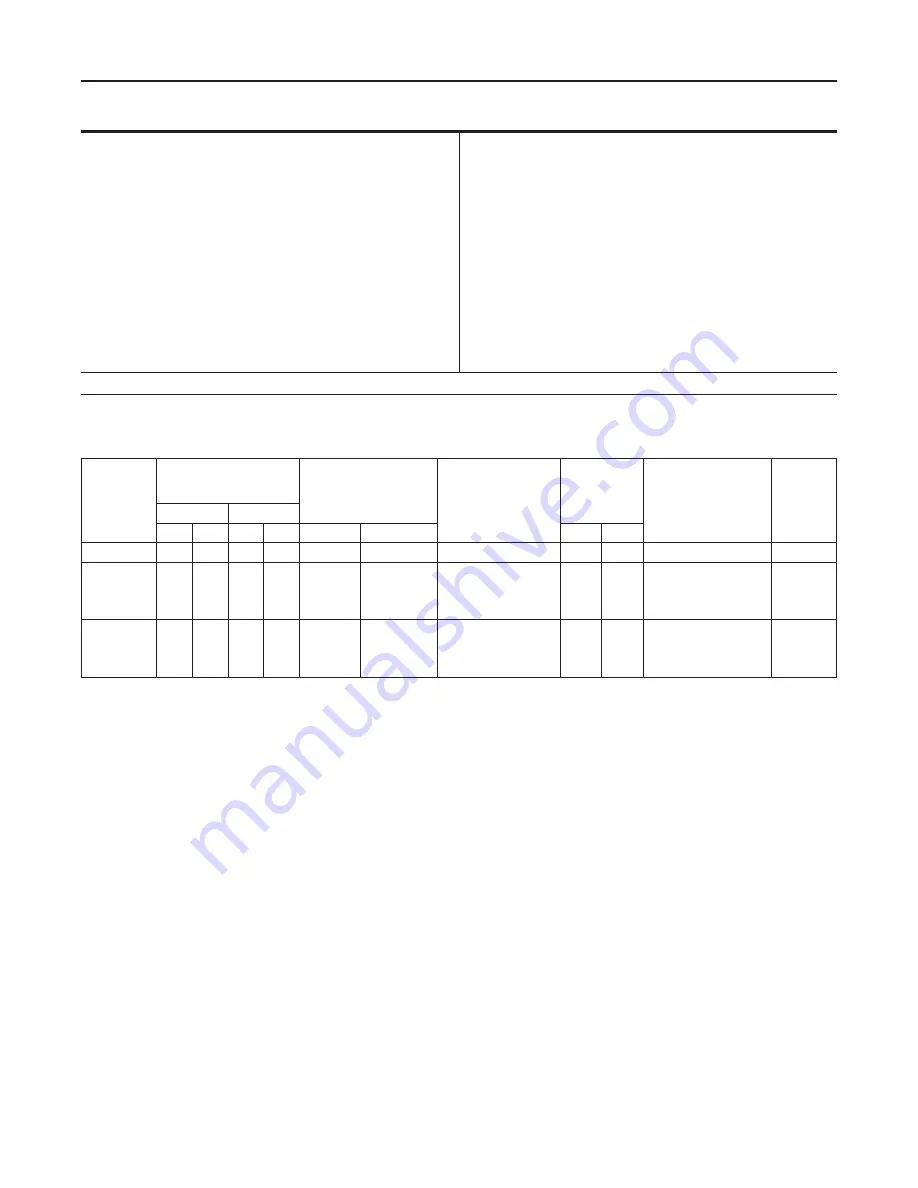

Table 1.

Maximum Pressures and Spring Part Numbers

compleTe

SWITcHIng

ValVe Type

number

DIapHragm preSSure

cHange beTWeen

SWITcHIng poInTS

DIapHragm

preSSure range

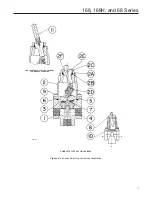

key 8, fIgure 3

DIapHragm SprIng

parT number anD

color coDe

maxImum

alloWable

boDy

preSSure

key 2D, fIgure 4

boDy SprIng parT

number anD

color coDe

boDy

aSSembly

Type

number

minimum

maximum

psi

bar

psi

bar

psi

bar

psi

bar

- - - -

- - - - - - - - - - - - - - - -

- - - -

- - - -

- - - -

150

10,3

1U878037022, Metallic

68-2

168-1

168-2

168-3

168-4

10

10

10

7

0,69

0,69

0,69

0,48

58

38

58

38

4,00

2,62

4,00

2,62

2 to 60

2 to 40

2 to 60

2 to 40

0,14 to 4,14

0,14 to 2,76

0,14 to 4,14

0,14 to 2,76

1U877127142, green

1U879727142, yellow

1U877127142, green

1U879727142, yellow

150

150

40

40

10,3

10,3

2,76

2,76

1U878037022, Metallic

1U878037022, Metallic

1U854537022, Yellow

1U854537022, Yellow

68-1

68-1

68-3

68-3

168H-1

168H-2

168H-3

168H-4

20

20

20

16

1,38

1,38

1,38

1,10

100

65

100

65

6,90

4,48

6,90

4,48

50 to 150

35 to 100

50 to 150

35 to 100

3,45 to 10,3

2,41 to 6,90

3,45 to 10,3

2,41 to 6,90

1U877127142, green

1U879727142, yellow

1U877127142, green

1U879724142, yellow

150

150

40

40

10,3

10,3

2,76

2,76

1U878037022, Metallic

1U878037022, Metallic

1U854537022, Yellow

1U854537022, Yellow

68-1

68-1

68-3

68-3

Installation

Maximum allowable pressures for the diaphragm and

body are given in the Specifications section above and

Table 1 respectively. If pressure to the unit is capable

of exceeding these values, install relief valves or other

overpressure protection devices in the pressure lines.

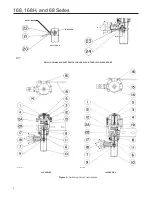

The 68 Series body assemblies can be installed in any

position. Position a 168 or 168H Series switching valve

so that moisture and other foreign material cannot enter

either the vent (key 17, Figure 3) or the small hole in the

end of the stem protector (key 10, Figure 3).

When the switch is in service, inspect the vent opening

periodically to ensure that it is not plugged.

Before installing, be certain that the valve body

portion and adjacent pipes are free of pipe scale and

other foreign material. Use accepted piping practices

when installing.

For the 168 and 168H Series switching valves, a

mounting bracket (key 15, Figure 3) is available. This

mounting bracket is suitable for use with a 2-inch

(50,8 mm) (nominal) pipestand. Mounting parts that

can be used to attach a 168 or 168H Series switching

valve to the yoke of a control valve actuator are

also available.

Pipe the common pressure line to port A (the

connection in the end of the valve body portion). With

one port (either B or C) plugged, the unit can be used

as an on/off switch. Note that flow cannot pass from

port B to port C or from port C to port B.