168, 168H, and 68 Series

3

168 and 168H Series adjustment

Determine the desired upper and lower switching

pressures (the high and low values of diaphragm

pressure at which the valve is to switch). Refer to

Table 1 to ensure that these pressures are within the

diaphragm pressure range and that the diaphragm

pressure change between the switching pressures is

within the minimum and maximum limits shown.

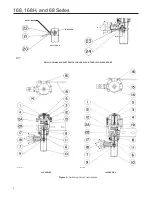

Adjust the unit as follows. Key numbers used in this

procedure are shown in Figure 3 except where indicated.

1. Remove screws and stem protector (keys 11

and 10).

2. To set the lower switching pressure:

2.1 Apply a pressure to the diaphragm case (key 1)

equal to the lower switching point.

2.2 Loosen locknut (key 9). Use a screwdriver

to move the trip lever (key 2C) so that the

visible end points away from the spring case

(key 2A). It might be necessary to back the

adjusting nut (key 7) and locknut away from

the trip lever to do this.

2.3 Rotate the adjusting nut toward the trip lever

until the nut just moves the trip lever to the

alternate position.

3. To set the upper switching pressure:

3.1 Apply a pressure to the diaphragm case (key 1)

equal to the upper switching pint.

3.2 Loosen the locknut on the upper range

adjusting nut. Use a screwdriver to move

the trip lever (key 2C) so that its visible

end points toward the spring case (key 2A).

It may be necessary to back the adjusting

nut and locknut away from the trip lever to

do this.

3.3 Rotate the upper range adjusting nut toward

the trip lever until the nut just moves the trip

lever to its alternate position.

4. Tighten each locknut against its respective

adjusting nut.

5. Replace stem protector and machine screws

(key 11).

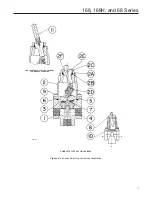

168 and 168H Series manual

reset operation

Without manual reset Switch

With one adjusting nut removed, the unit will switch

with high (or low) diaphragm pressure and will remain in

that position until the stem protector (key 10, Figure 3) is

removed and the trip lever (key 2C, Figure 4) is manually

moved to its normal position. Remove the range

adjusting nut (and its locknut) located nearer the spring

case (key 2A, Figure 3) if switching at low diaphragm

pressure only is desired. Remove the other adjusting

nut and locknut if switching with high diaphragm

pressure only is desired. The remaining adjusting nut

can be adjusted by the appropriate steps given in the

Adjustment section.

To reset the unit after it has switched, remove the

machine screws and stem protector (keys 11 and 10,

Figure 3), and use a screwdriver to return the trip lever

(key 2C, Figure 4) to its normal position.

With manual reset Switch

When a manual reset switch (see Figure 3) is used

on a unit in the single-pressure trip mode (either high

or low pressure setpoint requiring only one adjusting

nut), the end of the reset lever (key 20) in contact

with the trip lever (see section DD, Figure 3) should

be on the opposite side of the trip lever from the

adjusting nut.

If it is necessary to change the reset lever position,

remove the self tapping screws (key 23). Slide the lever

out of the stem protector slots, and position it on the

other side of the trip lever and re-insert. Re-attach the

indicator tag with the self-tapping screws, making sure

the arrow on the tag points in the same direction as

that required to reset the switch.