2100 and 2100E Liquid Level Switches

Instruction Manual

Form 5039

December 2005

6

A3619-2/IL

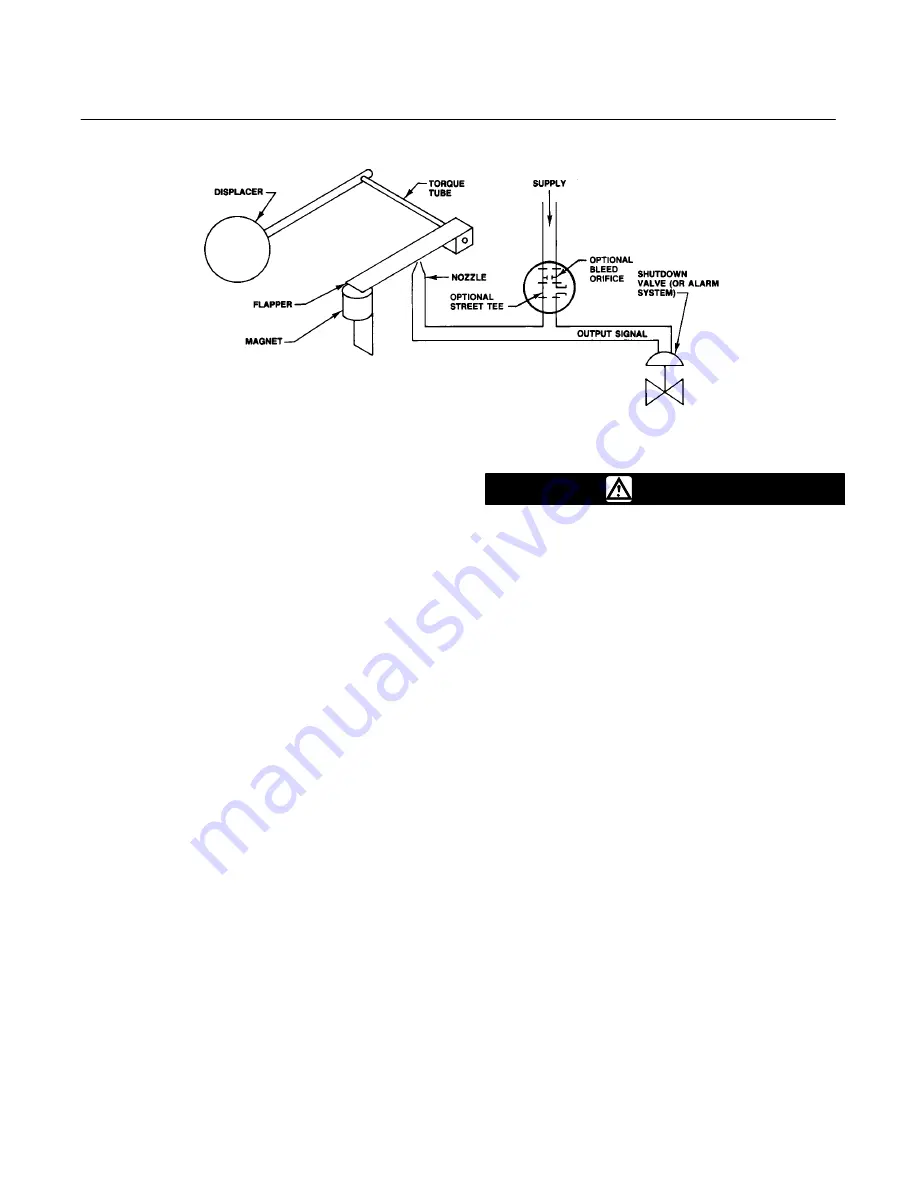

Figure 4. Principle of Operation for High-Level Type 2100 Switch

The reduced pressure in the output signal line

activates the shutdown or alarm system. When the

liquid level lowers, the falling displacer forces the

flapper into the field of the magnet, letting the

magnet snap the flapper against the nozzle and

causing output pressure to build to full supply

pressure.

On applications where low-level switch operation is

required, the nozzle, flapper, and magnet are

positioned on the opposite side of the torque tube so

that downward displacer travel moves the flapper

away from the nozzle.

The Type 2100E switch is an external,

cage-mounted, electric liquid level switch. Rising

liquid level exerts a buoyant force on the torque tube

that either activates or deactivates an electrical

SPDT (single-pole, double-throw) or DPDT

(double-pole, double-throw) switch depending on the

required switching action. Falling liquid level

deactivates or activates the same switch depending

on the required action.

Maintenance

Switch parts are subject to normal wear and must be

inspected and replaced when necessary. The

frequency of inspection and replacement depends

on the severity of service conditions.

Refer to figure 5 for maintenance of the Type 2100

switch and figure 6 for maintenance of the Type

2100E switch.

WARNING

Always wear protective clothing,

gloves, and eyewear when performing

any maintenance procedures to avoid

personal injury.

The displacer is a sealed container

inside the cage. A displacer penetrated

by process fluid may retain pressure

or hazardous fluid for an extended

period. Such a displacer may contain

pressure as a result of being in a

pressurized vessel, or it may contain

fluid that becomes pressurized due to

changes in temperature and/or it may

contain fluid that is hazardous or

flammable. The sudden release of

pressure, contact with hazardous fluid,

fire, or explosion resulting in personal

injury can occur if a displacer that is

retaining pressure or process fluid is

punctured or subjected to heat. Handle

the cage (with displacer inside) with

care in removing, storing, or

disposing, taking into consideration

the characteristics of the process fluid.

To avoid personal injury and damage

to the process system caused by the

sudden release of pressure, contact

with hazardous fluid, fire, or explosion,

isolate and drain the displacer cage.