BYPASSING & ISOLATING

(continued)

3--3

RETURN TO SERVICE

This procedure explains how to return the Automatic

Transfer Switch to service after inspection and

maintenance. Observe the ATS POSITION lights on the

STATUS INDICATOR panel.

1. Install the Transfer Switch into the enclosure.

Carefully follow directions on page 3–2.

Close enclosure door to prevent personal

injury in case of electrical system fault.

!

2.. Install the Isolation Handle (through the door) and

turn it clockwise (approximately 7 or 8 turns) until the

TEST

light comes on,

DISCONNECTED

light off.

NOTE

: If the emergency source is available, the

Automatic Transfer Switch may operate to the

emergency position. If it does, operate the door–

mounted

RESET TO NORMAL

toggle switch.

Electrical Operation Te

s

t

: This procedure will check the

electrical operation of the Automatic Transfer Switch

without interrupting the load. It still should be Bypassed

and in the

TEST

position. The engine starting control

should be in the

automatic

position.

Transfer Test

Perform the 5–step

Transfer Test

procedure on page 1–7.

The isolating contacts cannot be closed until the Transfer

Switch is in the

same

position as the Bypass Switch.

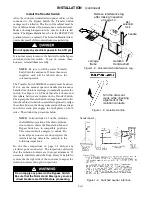

3. Observe which Bypass Switch

CLOSED ON

light is on

(

NORMAL

or

EMERGENCY

) on the

STATUS

INDICATOR

panel as shown in Figure 3-7. This light

indicates the source connected to the load.

4. Observe which Transfer Switch

CLOSED ON

light is

on (

NORMAL

or

EMERGENCY

).

This light

indicates the position of the Transfer Switch. If it is

not in the same position as the Bypass Switch, change

the Transfer Switch position as follows.

To change the position of transfer switch

Operate to NORMAL

Operate to EMERGENCY

Turn

Transfer Control

switch counterclockwise

to

Retransfer Delay By-

pass

.

Turn

Transfer Control

switch clockwise to

Transfer

Test

and hold.*

Transfer Switch Con-

nected to Normal

light

should come on.

Transfer Switch Connected

to Emergency

light should

come on.

* If Feature 2B time delay is used, there will be a delay

before transfer to Emergency.

NOTE: With Normal available, the Automatic

Transfer Switch will not stay in the emergency

position unless Feature 3A time delay is used

(at least 30 seconds).

Figure 3-7 . Status Indicator Panel

Do not close the isolating contacts unless

the transfer switch and bypass switch

are in the same postion.

!

5. Turn the Isolation Handle and turn it clockwise until

it stops (approximately 6 or 7 turns). The

CONNECTED

light should come on,

TEST

light off.

6. Remove the Isolation Handle and store it inside the

enclosure on the right side.

7. Turn Bypass Handle

clockwise as shown in

Figure 3-8 to

AUTO-

MATIC POS.

The By-

pass Switch

CLOSED

ON

NORMAL

or

EMERGENCY

light

should go off.

Figure 3-8 Turn Bypass Handle to AUTOMATIC.

The Automatic Transfer & Bypass Isolation Switch should

be left in this position.