5

Model No.: ACF552

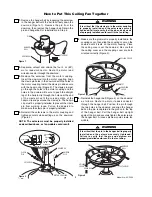

8.

Turn fan assembly upside down in preparation for

mounting fan blade assemblies.

9.

Remove and discard the five shipping spacers and

screws from the motor hub (Figure 5).

10.

Mount a blade flange to fan blades using three

M5 x 6mm washer head blade screws (Figure 6).

Be sure the raised edge of the fan blade is facing

up. Repeat this procedure for the remaining four

blades and fan blade flanges.

NOTE: Take care not to scratch fan housing when

installing blades.

SHIPPING

SPACER (4)

SHIPPING SPACER

SCREW (4)

N

O

T

E

!

R

e

m

o

ve

R

ub

be

r P

ac

D

is

ca

rd

B

e

fo

re

In

st

al

la

tio

MOTOR HUB

Figure 5

FAN BLADE FLANGES (5)

M5 x 6mm WASHER

HEAD BLADE SCREW (3)

FAN BLADE (5)

Figure 6

To reduce the risk of personal injury, do not bend the

blade holder when installing the blade holders,

balancing the blades or cleaning the fan. Do not

insert foreign objects in between rotating fan blades.

WARNING

!

13.

Remove one M4 x 10mm serrated pan head

screw from the lower housing adapter (reserve

for later use). Loosen the other two screws to

assemble the switch cup cover to the lower

housing adapter (Figure 7).

14.

Install the switch cup cover onto the lower

housing adapter by aligning the two key holes in

the switch cup cover with the two screws

loosened in Step 13. Rotate the switch cup cover

clockwise to engage the loosened screws into the

two key hole slots. Align the third hole in the

cover with vacant threaded hole on the lower

housing adapter. Re-install the screw removed in

Step 13 into the aligned holes. Securely tighten

all three screws (figure 8).

NOTE: Make sure wires are not pinched between

switch cup cover and lower housing adapter.

BLADE ASSEMBLY

M6 x 14mm CAPTIVE

SCREW WITH

LOCKWASER

REMOVE ONE M4 x 10mm SERRATED

PAN HEAD SCREW

LOWER HOUSING

ADAPTER

Figure 7

M4 x 10mm

SERRATED PAN

HEAD SCREW (3)

ROTATE SWITCH CUP

COVER CLOCKWISE

SWITCH CUP

COVER

Figure 8

12.

The fan blade holders have an interlocking

feature that must be fully engaged before

tightening the screw. Make sure all the holders

are properly engaged and then tighten the holder

screws. If one of the fan blade holders does not

seat properly on the motor hub, loosen the

adjacent holder screws, re-engage and reseat

the holders, then tighten the screws again.

7.

The motor lead wires will require shortening if

using a 1.5 m. or shorter downrod. The fan comes

with blue, brown, orange and green/yellow motor

leads that are 2 m. (80") long. Measure up

approximately 15 cm. (6") above top of hanger

ball/downrod assembly and cut off the excess lead

wire. Strip back the wire insulation as follows:

A. Green/yellow wire - 10 mm. from the cut end.

B. Blue/brown/orange - 8 mm. from the cut end.

Twist all wire tips a minimum of 2 turns.

11.

Loosely attach one blade assembly to the motor

hub using two M6 x 14 captive pan head screws

with lockwashers installed on the fan blade

holders. Make sure the screws are NOT

tightened. (Figure 7.) Repeat this procedure for

other four blade assemblies.