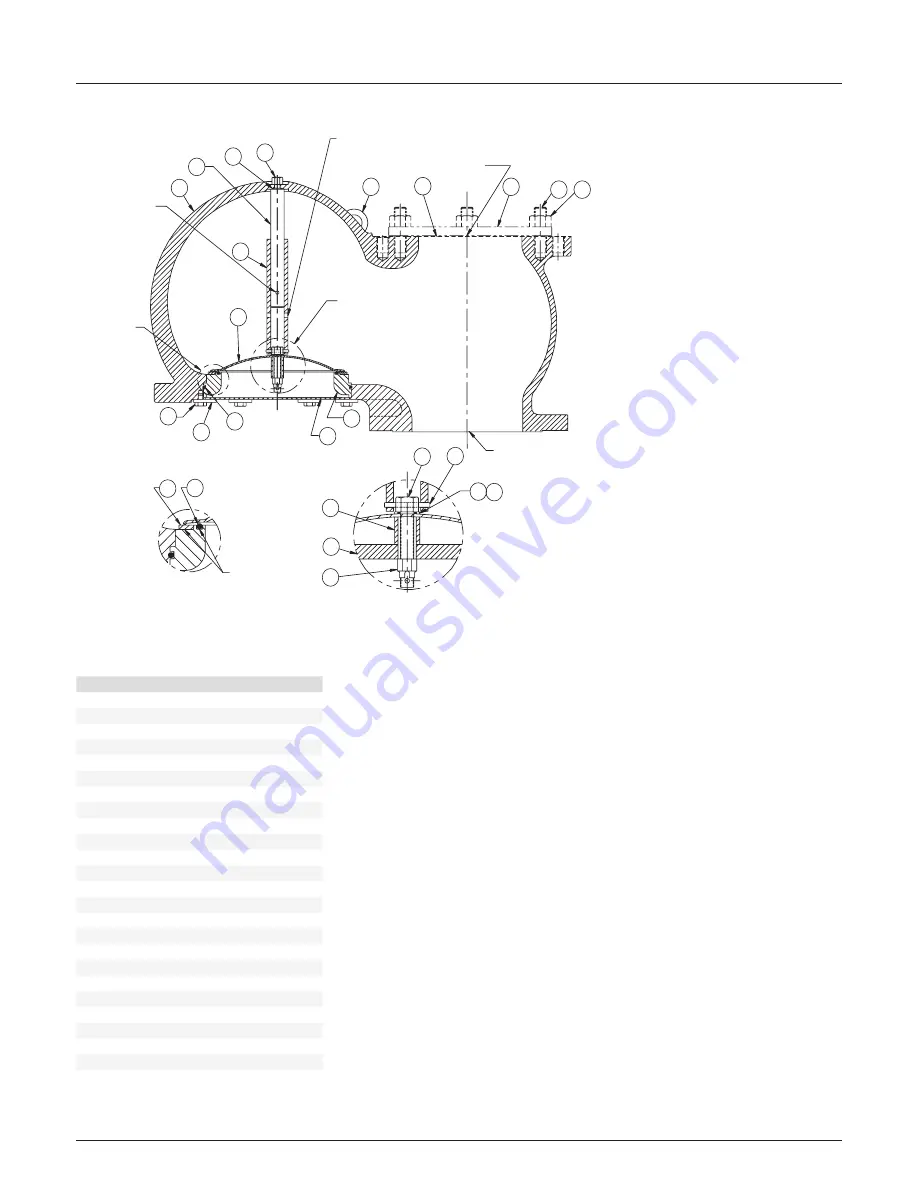

4

1

6

9

8

27

21

19 20

18

7

2

5

4

11

14

13

17

12

16

10

23

24

16

25 26

ANDERSON GREENWOOD

SERIES 96A VACUUM BREAKER

INSTALLATION AND MAINTENANCE INSTRUCTIONS

PARTSLIST

Item

Description

1

Body

2

Nut-lock

4

Pin-spring

5

Bolt-seat bolt

6

Rod-guide

7

Tube-guide

8

Bolt-guide rod

9

O-ring

10

Seat-sponge

11

Plate-seat

12

Screen-inlet

13

Retainer-seat ring

14

Bolt-retainer

15

Ring-seat

16

O-ring, Seat plate

17

O-ring, Seat ring

18

Cap-outlet

19

Stud

20

Nut

21

Gasket

23

Weight-ring

24

Spacer

25

Retainer-O-ring

26

O-ring

27

Eyebolt

ø.249 - .269 (ø6.32 - 6.83 mm)

Cross drill hole

ø.280 - .288

(ø7.11 - 7.32 mm)

Cross drill hole

See detail B

See detail A

Relief valve connection, 150 # FFSF

Tank connection

½ oz set

(0.22 kpag)

Apply adhesive

to this surface

Detail A

1½ oz set (0.65 kpag)

Detail B

FIGURE 1