November 2021

Installation, Operation and Maintenance Manual

DOC.IOM.RG.US Rev. 11

18

Section 10: Operator Information

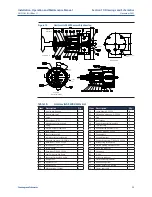

Operator Information

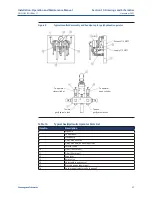

Table 3.

Typical gas/hydraulic Parts List (Quarter-turn Operators)

Item Description

Material

Qty.

Note

1

Drive Case

Tenzaloy 713

1

2

Cover

Tenzaloy 713

1

3

Yoke

ASTM A148 or DI

1

4

Drive Rod

AISI 4140 HTSR QPQ Liquid Nitriding

1

5

Drive Pin

AISI 4140 Heat Treated

1

6

Drive Roller

AISI4140 Carburized

2

7

Cylinder Plate

ASTM A516-70

2

8

End Cap

ASTM A516-70

2

9

Piston

ASTM A516-70

2

10

Cylinder

C1026

2

11

Tie Rod

AISI 4140

16

(V)

12

Yoke Cover

Tenzaloy 713

1

13

End Stop

ASTM A193 GR. B7

2

14

Cylinder Plate Capscrew

SAE Gr. 5 Plated

6

(V)

15

Cover Capscrew

SAE Gr. 5 Plated

10

16

Yoke Cover Capscrew

SAE Gr. 5 Plated

4

17

Tie Rod Nut

ASTM A194 Gr. 2H

16

18

Piston Capscrew

SAE Gr. 8 Plated

2

(V)

19

End Stop Cover

ASTM A194 Gr. 2H

2

21

Tie Rod Lockwasher

SAE 1060 Plated

16

(V)

23

Snap Ring

SAE 1075 Heat Treated

2

24

Yoke O-Ring

Nitrile

1

(Y)

25

End Stop O-Ring

Nitrile

2

(Y)

26

Piston Center O-Ring

Nitrile

2

(Y)

27

Drive Rod Seal

Urethane/MoS

2

/Nitrile

2

(Y)

28

Cylinder O-Ring

Nitrile

4

(Y)

29

Piston Seal

Urethane/MoS

2

/Nitrile

4

(Y)

30

Drive Rod Guide

Acetal

2

31

Yoke Bushing

C1020

2

(C)

32

Yoke Bearing

Nylon

1

34

Position Indicator

C1010

1

35

Piston Wear Ring

Nylon/MoS

2

2

36

Cylinder Plate Polypak

Molythane

2

(Y)

37

Inpspection Hole Plug

Polythylene

1

(V)

38

NPT Port

-

4

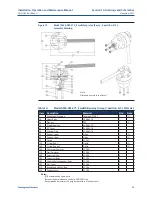

Table 4.

Pressure Vessels Specifications

NOTE:

-

(C) Chrome Plated

-

(N) Not Shown

-

(Y) Spare Parts Kit

-

(V) Quantity may vary depending on model

-

(**) Impact tested as per ASTM A370 18J average, 14J minimum, -50 °F (-46 °C), CVN full size

-

All metal parts coated with corrosion inhibitor.

-

All specifications are subject to change or upgrade.

Pressure Vessels

Note

A

-50 °F to 150 °F

(-46 °C to 65 °C)

Shell

ASME SA-333 Gr. 6

(N)

Head

ASME SA-420-WPL6/ASME SA-516-70

(**)

Fittings

ASME SA-350-LF2

B

-20 °F to 150 °F

(-29 °C to 65 °C)

Shell

ASME SA-106 Gr. B

Head

ASME SA-234-WPB/ASME SA-516-70

Fittings

ASME SA105/ASME SA-350-LF2