November 2021

Installation, Operation and Maintenance Manual

DOC.IOM.RG.US Rev. 11

16

Section 9: Instruction to Set End of Stroke

Instructions to Set End of Stroke

Section 9: Instructions to Set End of Stroke

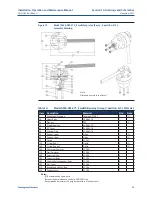

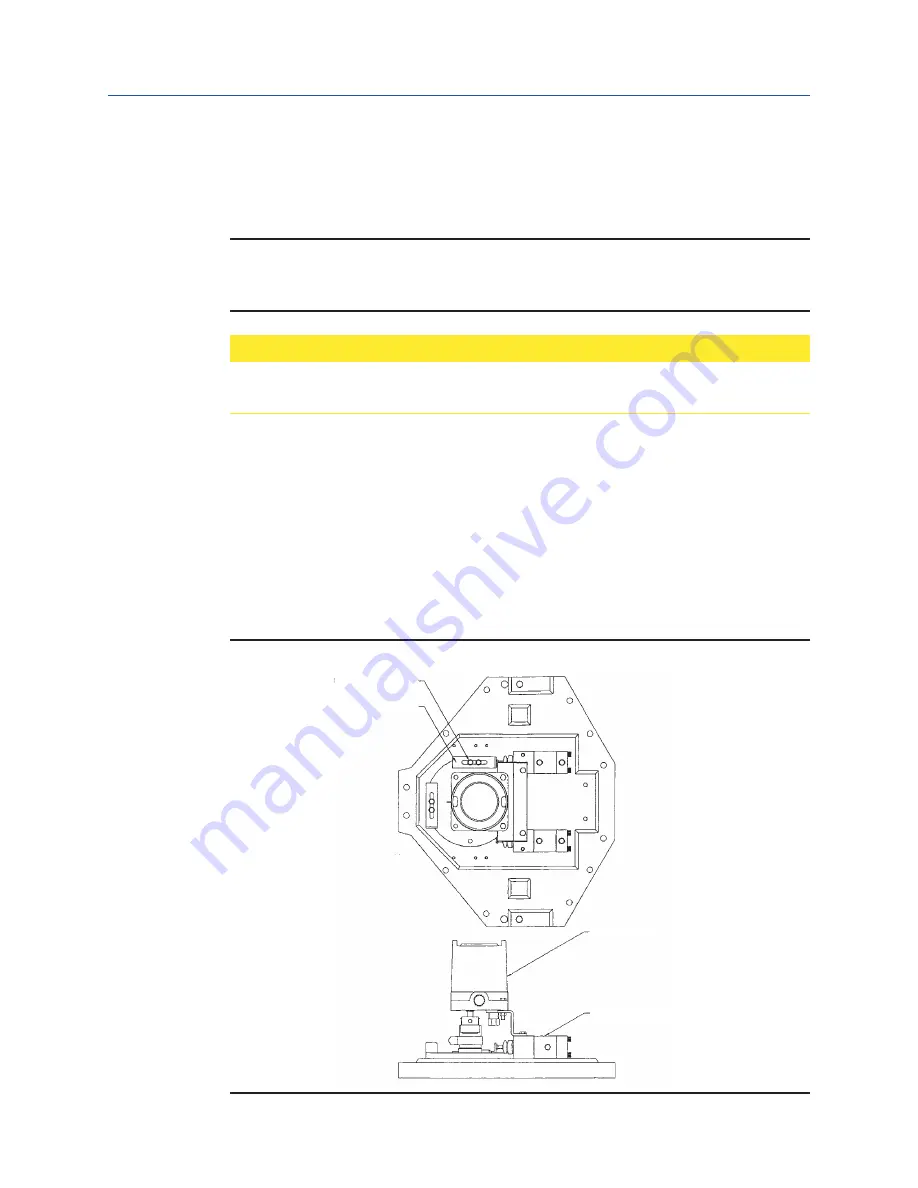

Refer to Figure 4.

NOTE:

Operator stops must be set for valve travel before attempting adjustments.

Determine operator/valve position (open/closed position) before making adjustments.

!

CAUTION

Changing operator travel can cause damage to end of stroke (trigger) valve if over travel occurs and

trigger strikes component.

The "End of Stroke" (Trigger Valve) ensures that gas/hydraulic tanks and cylinders are de-pressurized

at the end of each automatic operation as required.

1.

Loosen trigger bolts, so trigger can be slid forward to actuate trigger valve.

2.

Holding trigger in position such that trigger valve has switched and sealed, tighten bolts.

3.

Operate operator to check trigger valve operation. At the end of the stroke, the trigger

valve should switch and seal properly.

4.

If trigger valve is not sealing properly after operation, loosen bolts, adjust trigger forward

and re-tighten.

Approximately 1/4 inch minimum of trigger travel is required.

Figure 4

Typical limit switch layout for switchpak with end of stroke valve

Bolt, trigger clamping

Trigger

Switchpak

End of stroke valve