April 2016

Installation, Operation and Maintenance Manual

RGS011110-2 Rev. 0

11

Section 4: Maintenance

Maintenance

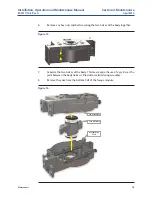

4.

Remove the end cap. Be careful not to lose the cylinder seal located on the

internal side of the end cap.

Figure 7

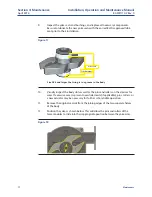

5.

Remove the cylinder. Be careful not to damage the internal surface of the

cylinder as this will compromise the piston’s ability to seal.

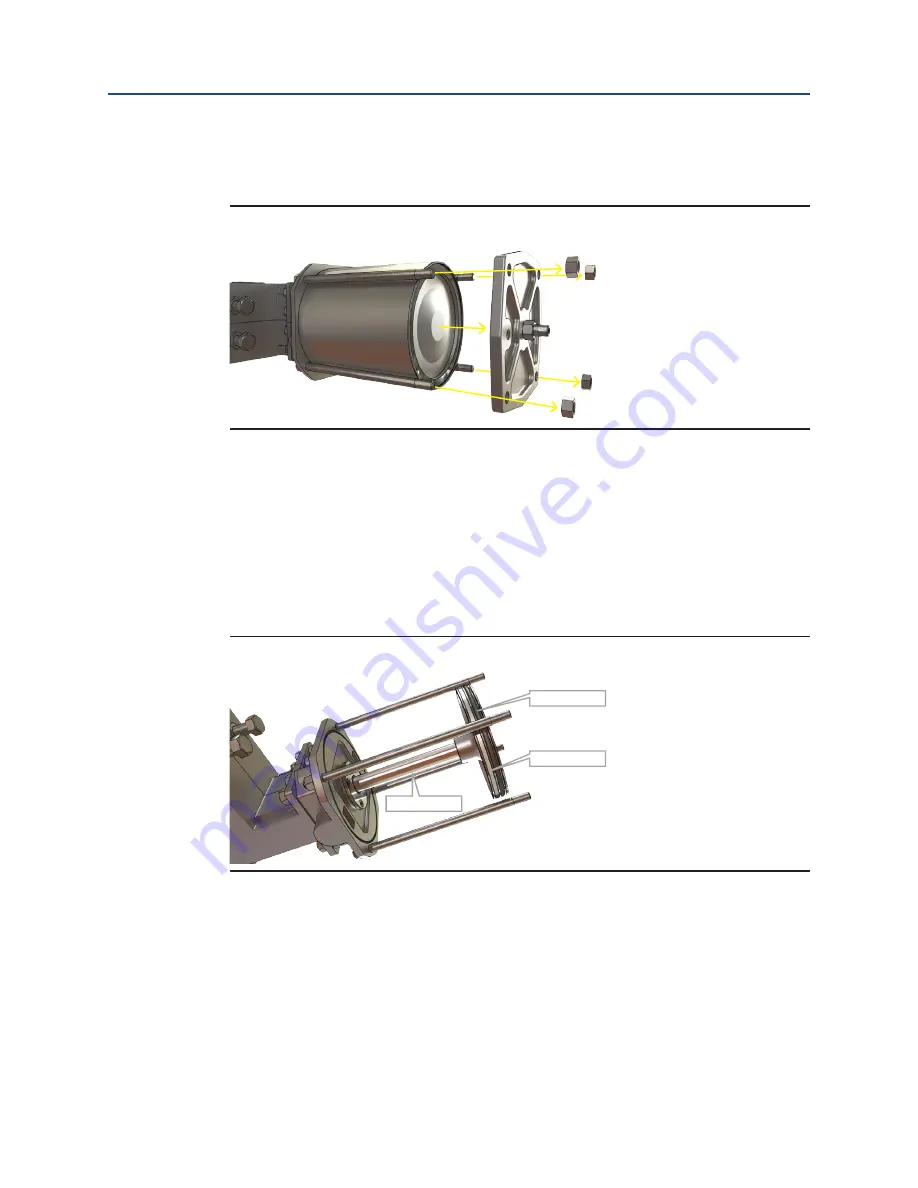

6.

Replace the piston O-ring and wiper ring as needed. Be sure to lubricate the new

O-ring and wiper ring with the correct Bettis approved lubricant if they are

replaced.

7.

Inspect the piston bolt for any corrosion or wear (pitting, cracking). If excessive

corrosion or wear is apparent, a new actuator or actuator components may

be necessary.

Figure 8

Piston O-ring

Wiper Ring

Piston Bolt

8.

Lubricate the internal surface of the cylinder with a light coat of the correct

Bettis approved lubricant and slide the cylinder back over the piston and into the

cylinder seal groove of the base plate, taking care not to pinch the piston O-ring.

9.

Place the end cap back over the tie rods. Be sure that the cylinder is seated

in the cylinder seal groove of the end cap with the cylinder seal still in place

between the cylinder and the end cap.