Installation, Operation and Maintenance Manual

RGS011110-2 Rev. 0

April 2016

14

Section 4: Maintenance

Maintenance

5.

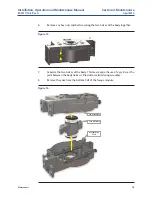

Remove the seal retainer and seal carrier.

Figure 12

Seal Carrier

Seal Retainer

6.

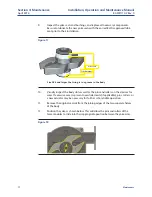

Lubricate the new seal carrier, piston bolt, the internal and external seal carrier

O-rings.

7.

Place the internal and external seal carrier O-rings in their respective grooves on

the seal carrier.

8.

Slide the seal carrier back over the open end of the piston bolt with the external

seal carrier O-ring facing the base plate. Be careful not to damage the internal

seal carrier O-ring on the threads of the piston bolt.

9.

Secure the seal carrier with the seal retainer and the socket head cap screws

removed in step four. Apply medium strength thread locker and torque to

44 in-lb (5 Nm).

10.

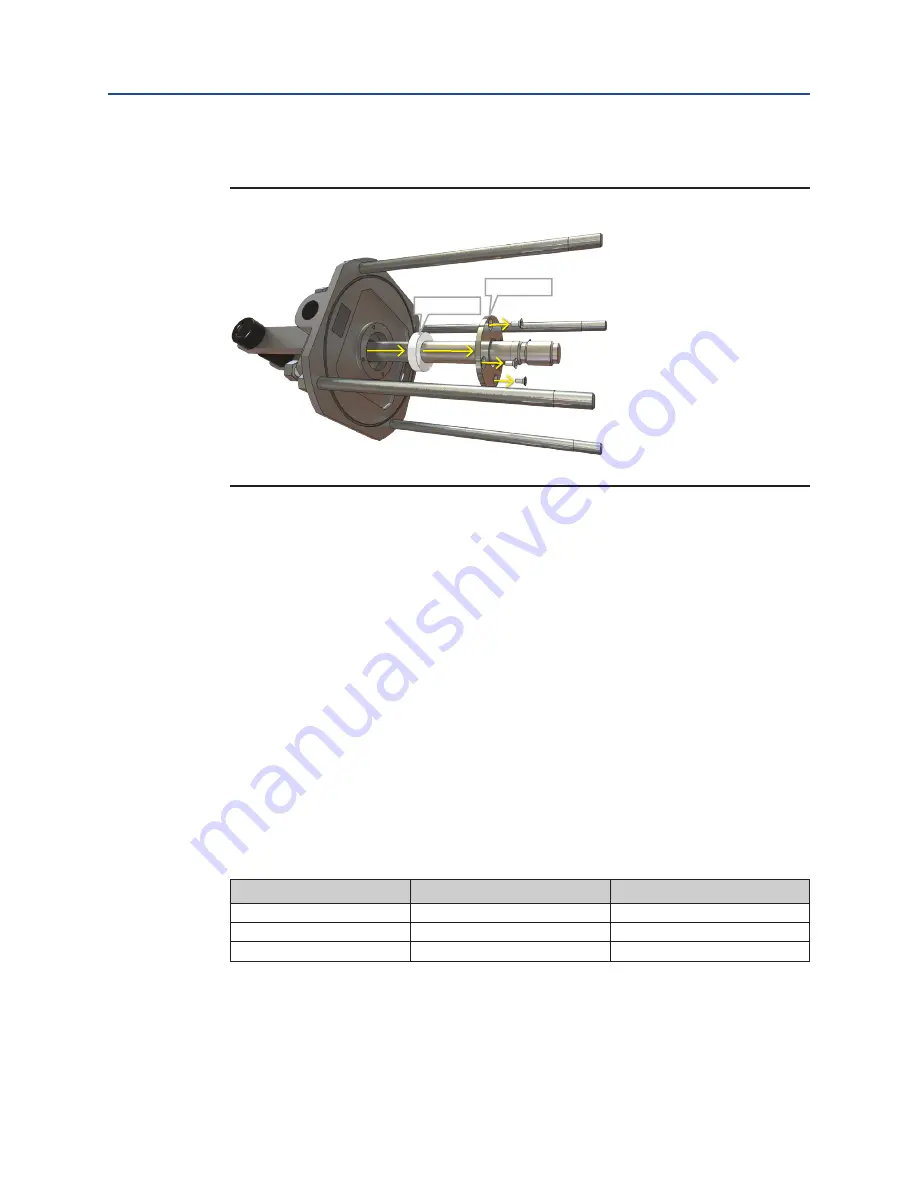

Apply medium strength thread locker to the internal threads of the piston and

thread the piston back onto the piston bolt to the point of refusal.

11.

Apply medium strength thread locker to the piston set screw and thread the set

screw into the neck of the piston. Torque the set screw to the corresponding

value in the table below.

Table 4�

Piston Size (In)

Ft-Lbs

Nm

6

14

18

8, 10, 12, 16

28

37

20, 24

47

65

12.

Follow steps 8 to 10 of Section 4.3.

13.

Repeat steps 1 to 12 of this section on the second force module.