April 2016

Installation, Operation and Maintenance Manual

RGS011110-2 Rev. 0

15

Section 4: Maintenance

Maintenance

4�5

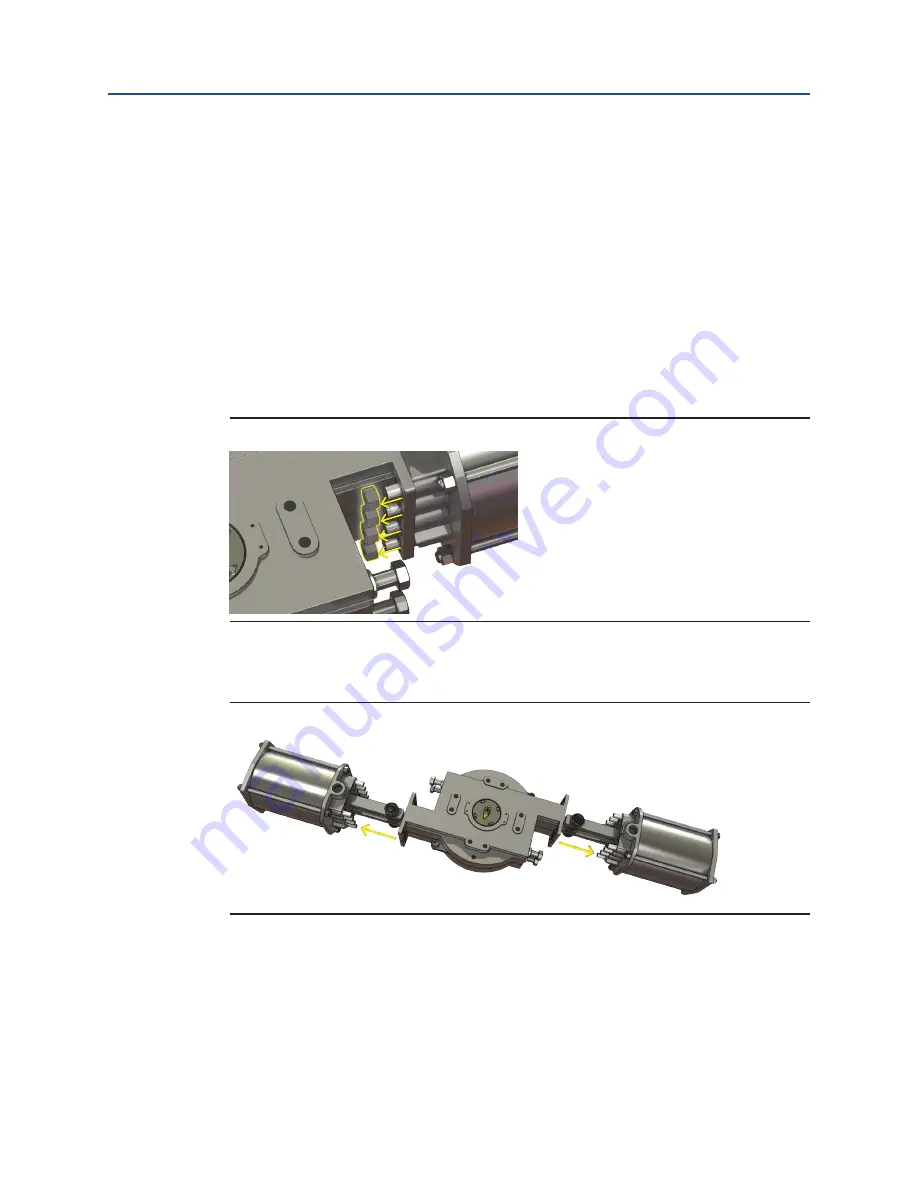

Yoke Seal and Bushing Replacement

In Bettis RGS F-Series actuators, the yoke seal does not serve any purpose other than to

prevent external contaminants from entering the torque module. The following steps

can be followed to replace the yoke seal and/or bushings.

1.

Depressurize the actuator and remove all supply lines.

2.

Remove the actuator from the valve.

3.

Ensure lockout (if provided) is disengaged.

4.

Remove the hex nuts which secure the force modules to the torque module of

the actuator. Do this for both force modules.

Figure 13

5.

Separate the force modules from the torque module. This can be done by

simply pulling the force modules away from the torque module simultaneously.

Figure 14