April 2016

Installation, Operation and Maintenance Manual

RGS011110-2 Rev. 0

17

Section 4: Maintenance

Maintenance

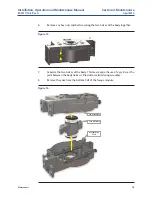

9.

Inspect the yoke seals and bushings, and replace all necessary components.

Be sure to lubricate the new yoke seals with the correct Bettis approved lubri-

cant prior to their installation.

Figure 17

Yoke Seals

Yoke Bushings

Size 488 and larger the O-ring is in a groove in the body

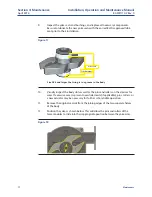

10.

Visually inspect the body slots as well as the pins and rollers on the clevises for

wear. If excessive wear is present new slide inserts(if applicable), pins, rollers, or

a new actuator may be necessary for further safe, reliable operation.

11.

Remove the original sealant from the joining edges of the two separate halves

of the body.

12.

Position the yoke as shown below. This will allow the pins and rollers of the

force modules to slide into their appropriate position between the yoke arms.

Figure 18