15. Carefully lift the fan and seat the hanger

ball/downrod assembly on the hanger bracket that

was just attached to the outlet box (Figure 9B). Be

sure the groove in the ball is lined up with the tab

on the hanger bracket (Figure 8B).

NOTE: If you are installing a SR330 Remote

Control or a SW350 Wall Control to operate the

fan and light, refer to the installation instructions

and wiring diagrams shown in SECTION A or this

Owner’s Manual.

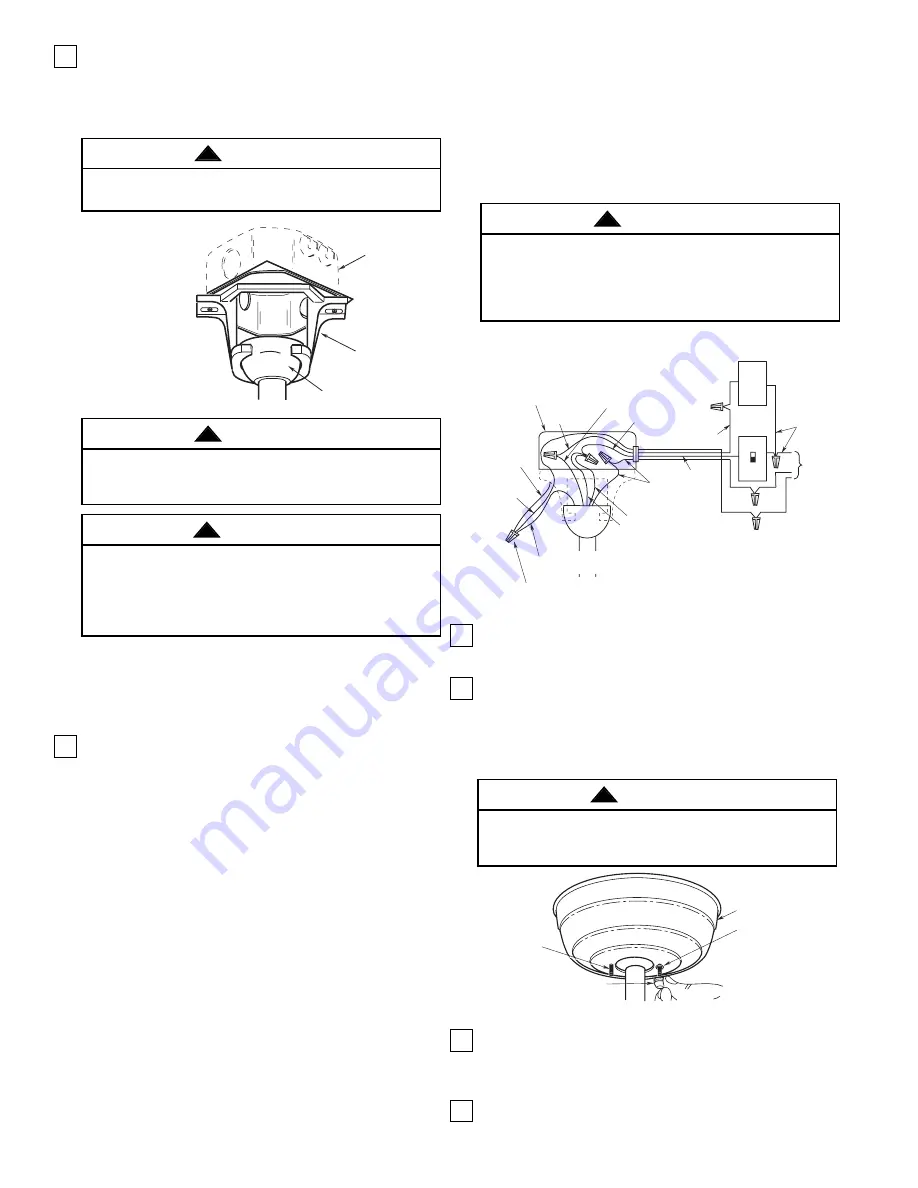

16. For a wall control installation you will need a three-

wire (with ground) conductor cable between the

ceiling and wall outlet boxes. This will allow you to

control the fan separately from the lights. Figure

10B is a basic wiring diagram that will control the

uplight and downlight on a switch and the fan on a

separate control. Refer to the installation

instructions and wiring diagrams supplied with the

Emerson Fan Control Owner’s Manual.

a.

Connect the green grounding lead from the

hanger ball and the green grounding lead

from the hanger bracket to the grounding

conductor of supply (this may be a bare wire

or a wire with green colored insulation).

Securely connect wires with wire connector

(supplied).

b. Securely connect the white wire from the

downrod to the supply white (neutral) wire

using wire connector (supplied). Securely

connect the black wire from the downrod to

the supply black (hot) wire using wire

connector (supplied).

c.

Cut terminal off of the yellow lead wire and

strip insulation 1/2” from end of wire.

d. Securely connect the blue wire and yellow

wire from the downrod to the supply red (hot)

wire using wire connector (supplied). After

connections have been made, turn leads

upward and carefully push leads into the

outlet box, with the white and green leads on

one side of the outlet box and the black, blue

and yellow leads on the other side of the

outlet box.

17. Lift the ceiling cover up to the threaded studs and

turn until studs protrude through the holes in the

ceiling cover (Figure 11B).

18. Secure the ceiling cover in place by installing two

lockwashers and two knurled knobs (supplied)

(Figure 11B). Tighten the knurled knobs securely

until the ceiling cover fits snugly against the

ceiling and the hole in the ceiling cover is clear of

the downrod.

19. Use three 10-32 x 3/8” pan head screws and flat

washers (supplied) to secure the flange to the blade

(ordered separately) (Figure 12B). Repeat for the

four remaining blades.

20. Use the 10 round recessed holes in the motor hub

marked with “5” and install the five blade

assemblies in accordance with Step 21.

12

Failure to seat tab in groove could cause damage to

electrical wires and possible shock or fire hazard.

WARNING

!

OUTLET

BOX

HANGER

BRACKET

HANGER BALL/

DOWNROD ASSEMBLY

Figure 3

NOTE: CEILING COVER,

SUPPLY WIRES AND

FAN WIRES OMITTED

FOR CLARITY.

Figure 9B

To avoid possible fire or shock, do not pinch wires

between the hanger ball/downrod assembly and the

hanger bracket.

WARNING

!

BLACK

BLACK FAN WIRE

LISTED OUTLET BOX

LIGHT

CONTROL

GREEN WIRE

(GROUND)

FROM

HANGER

BRACKET

TO 120

VOLT

SUPPLY

WHITE

WHITE

GROUND

GROUND

GREEN WIRE (GROUND)

FROM HANGER BALL

LISTED WIRE

CONNECTOR (4)

GROUND

WIRE

WHT.

RED

BLACK

EMERSON

FAN

CONTROL

BLACK

(HOT)

YELLOW

BLUE

RED

Figure 10B

Check to see that all connections are tight, including

ground, and that no bare wire is visible at the wire

connectors, except for the ground wire. Do not

operate fan until blades are in place. Noise and fan

damage could result.

WARNING

!

To avoid possible fire or shock, make sure that the

electrical wires are completely inside the outlet box and

not pinched between the ceiling cover and the ceiling.

WARNING

!

1-1/4"

THREADED

STUD

LOCKWASHERS (2)

CEILING COVER

KNURLED KNOB

Figure 11B

To avoid possible electrical shock, be sure electricity

is turned off at the main fuse box before wiring.

NOTE: If you are not sure if the outlet box is

grounded, contact a licensed electrician for advice,

as it must be grounded for safe operation.

WARNING

!