21. Attach one blade assembly to the motor hub using

two 10-32 x 5/8” oval head screws (supplied)

(Figure 13B). Do not tighten completely at this time.

Install remaining blade assemblies in the same

way. Gently snug all flange screws to the motor

hub, working around the hub in a clockwise

sequence. Next, securely tighten all flange screws,

again working in a clockwise sequence. Failure to

follow this procedure could result in fan wobble.

This completes the blade installation.

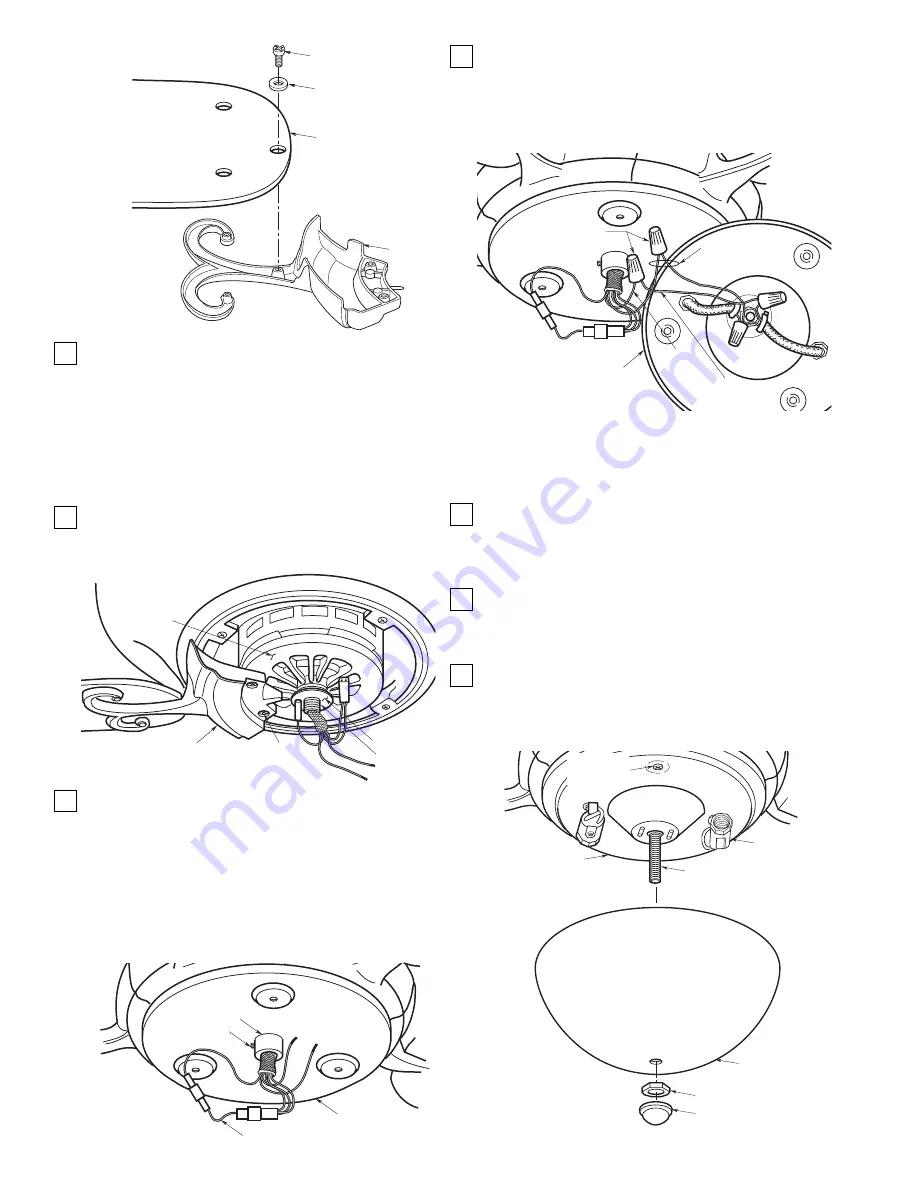

22. Pass the connectors and the wires from the motor

shaft through the washer (supplied) and position the

washer over the motor shaft (Figure 13B).

23. Using the 5/64” hex wrench (supplied), loosen the

setscrew in the collar on the light kit adapter

assembly. Then pass the connectors and the wires

from the motor shaft through the collar (Figure 14B).

Screw the adapter assembly onto the motor shaft

and then tighten the setscrew to secure the adapter

assembly to the motor shaft. Connect the

connectors from the motor shaft using the jumper

assembly (supplied). Verify that the connectors are

securely engaged.

24. Securely connect the black wire from the light kit

plate assembly to the blue wire from the motor shaft

using a wire connector (supplied) (Figure 15B).

Connect the white wire from the plate assembly to

the white wire form the motor shaft using a wire

connector (supplied).

NOTE: When installing the light kit plate

assembly, position the wires and wire connectors

in the raised center portion of the plate assembly.

Do not pinch wires between the light kit plate

assembly and the adapter assembly.

25. Secure the light kit plate assembly to the light kit

adapter assembly by threading three

5/32-32 x 3/16” phillips head screws (supplied) into

the threaded holes in the adapter assembly

(Figure 16B).

26. Install two candelabra base lamps in the sockets of

the light kit adapter plate (Figure 16B):

Model CF2600 - 15-Watt Maximum

Model CF2650 - 25-Watt Maximum

27. Position the glass shade over the threaded nipple in

the light kit plate assembly (Figure 16B). Seat the

glass shade evenly over the plate assembly and

securely install the hex nut and finial nut (supplied)

on the threaded nipple.

13

MOTOR HUB

BLADE FLANGE

10 - 32 x 5/8"

OVAL HEAD SCREW

(2 Per Blade Assembly)

WASHER

MOTOR

SHAFT

Figure 13B

BLADE

FLANGE

10-32 x 3/8"

PAN HEAD SCREW

FLAT WASHER

FAN BLADE

Figure 12B

LIGHT KIT

ADAPTER ASSEMBLY

JUMPER

ASSEMBLY

SETSCREW

COLLAR

Figure 14B

BLUE

WIRE

LIGHT KIT

PLATE ASSEMBLY

WIRE

CONNECTORS

BLACK

WIRE

WHITE WIRES

Figure 15B

LIGHT KIT

PLATE ASSEMBLY

SOCKET

THREADED NIPPLE

GLASS

SHADE,

LOWER

FINIAL

NUT

HEX NUT 1/8-27

5/32-32 x 3/16"

PHILLIPS HEAD

SCREW (3)

Figure 16B