15

Using Your Ceiling Fan

1. Restore electrical power to the outlet box by

turning the electricity on at the main fuse box.

2. Check the operation of the fan and lights by using

the wall controls or the remote control.

3. If airflow is desired in the opposite direction, turn

your fan off and wait for the blades to stop turning.

Then slide the reversing switch (located on top of

the housing) to the opposite position and turn the

fan on again. The fan blades will turn in the

opposite direction and reverse airflow.

Maintenance

IMPORTANT CARE INSTRUCTIONS

for your Ceiling Fan

Periodic cleaning of your new ceiling fan is the only

maintenance that is needed.

When cleaning, use only a soft brush or lint free cloth

to avoid scratching the finish.

Abrasive cleaning agents are not required and should

be avoided to prevent damage to finish.

Accessories

1. Ceiling Fan Controls (see store or catalog).

2. Downrod Extension Kits (see store or catalog).

Do not use water when cleaning your ceiling fan. It

could damage the motor or the blades and create the

possibility of an electrical shock.

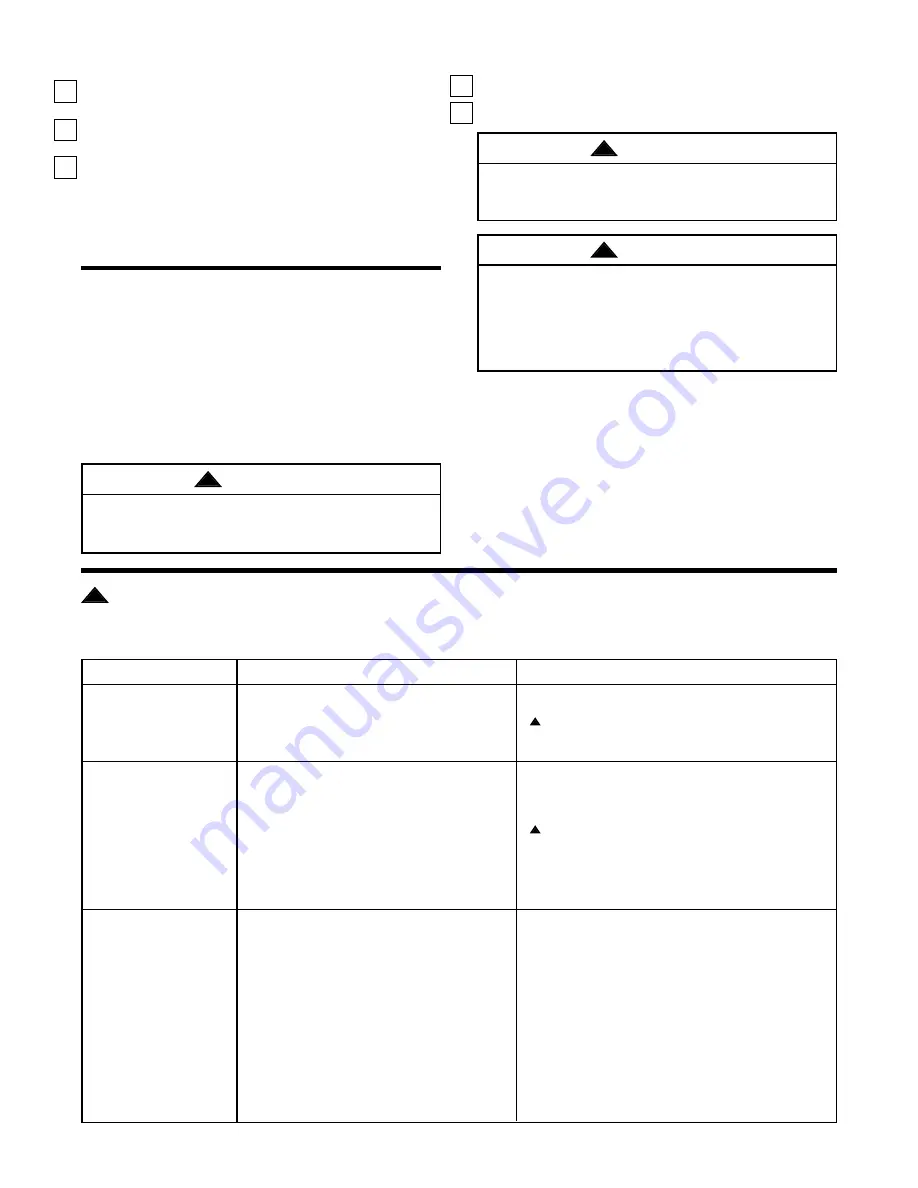

WARNING

!

This product is designed to use only those parts

supplied with this product and/or any accessories

designated specifically for use with this product by

Emerson. Substitution of parts or accessories not

designated for use with this product by Emerson

could result in personal injury or property damage.

WARNING

!

The use of any other control not specifically

approved for this fan could result in fire, shock and

personal injury.

WARNING

!

Trouble Shooting

TROUBLE

PROBABLE CAUSE

SUGGESTED REMEDY

1. Fan will not start.

1. Fuse or circuit breaker blown.

1. Check main and branch circuit fuses or circuit

breakers.

WARNING:

Make sure main power is turned off.

2. Loose power line connections to the fan, or loose

2. Check line wire connections to fan and switch

switch wire connections in the switch housing.

wire connections in the switch housing.

2. Fan sounds noisy.

1. Blades not attached to fan.

1. Attach blades to fan before operating.

2. Support rods loose.

2. Tighten the barrels of the rod assemblies.

3. Screws securing fan blade flanges to motor hub

3. Check to make sure the screws which attach

are loose.

the fan flanges to the motor hub are tight.

WARNING:

Make sure main power is turned off.

4. Wire connectors inside switch housing rattling.

4. Check to make sure wire connectors in

switch housing are not rattling against each

other or against the interior wall of the switch

housing.

5

Screws holding blades to flanges are loose.

5. Tighten screws securely.

3. Fan wobbles

1. Setscrew in motor coupling is loose.

1. Raise motor cover and tighten setscrew securely.

excessively

.

2. Setscrew in hanger ball/downrod assembly is

2. Tighten the setscrew in the hanger ball/downrod

loose.

assembly.

3. Screws securing fan blade flanges to motor hub

3. Check to be sure screws which attach the fan blade

are loose.

flanges to the motor hub are tight.

4. Fan blade flanges not seated properly.

4. Check to be sure the fan blade flanges seat firmly and

uniformly to the surface of the motor hub. If flanges are

seated incorrectly, loosen the flange screws and

retighten according to Step 29 in SECTION A or Step 21

in SECTION B.

5. Hanger bracket and/or ceiling outlet box is not

5. Tighten the hanger bracket screws to the outlet box,

securely fastened.

and/or secure outlet box.

6. Fan blades out of balance.

6. Interchanging an adjacent (side-by-side) blade pair can

redistribute the weight and result in smoother operation.

Or use supplied balancing kit to balance blades.

WARNING:

For your own safety, turn off power at fuse box or circuit breaker before trouble

shooting your fan.

!

!

!

Before discarding packaging material, be certain all

parts have been removed.

HOW TO ORDER REPAIR PARTS

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION:

• PART NUMBER

• PART DESCRIPTION

• NAME OF ITEM

• MODEL NUMBER

For repair parts, phone 1-800-654-3545.