6

To avoid possible fire or shock, do not pinch wires

between the hanger ball/downrod assembly and

hanger bracket.

WARNING

!

Electrical Requirements

If your fan is to replace an existing ceiling light fixture,

turn electricity off at the main fuse box at this time and

remove the existing light fixture.

Your new ceiling fan will require a grounded electrical

supply line of 120 volts AC, 60 Hz, 15 amp circuit.

The outlet box must be securely anchored and

capable of withstanding a load of at least 50 pounds.

Turning off wall switch is not sufficient. To avoid

possible electrical shock, be sure electricity is

turned off at the main fuse box before wiring. All

wiring must be in accordance with National and

Local Codes and the ceiling fan must be properly

grounded as a precaution against possible

electrical shock.

WARNING

!

To reduce the risk of fire, electrical shock, or personal

injury, mount fan to outlet box marked “Acceptable for

Fan Support”, and use screws supplied with outlet box.

Most outlet boxes commonly used for support of light

fixtures are not acceptable for fan support and may

need to be replaced. Consult a qualified electrician if

in doubt.

WARNING

!

U.L. Model No.: CF701

15.

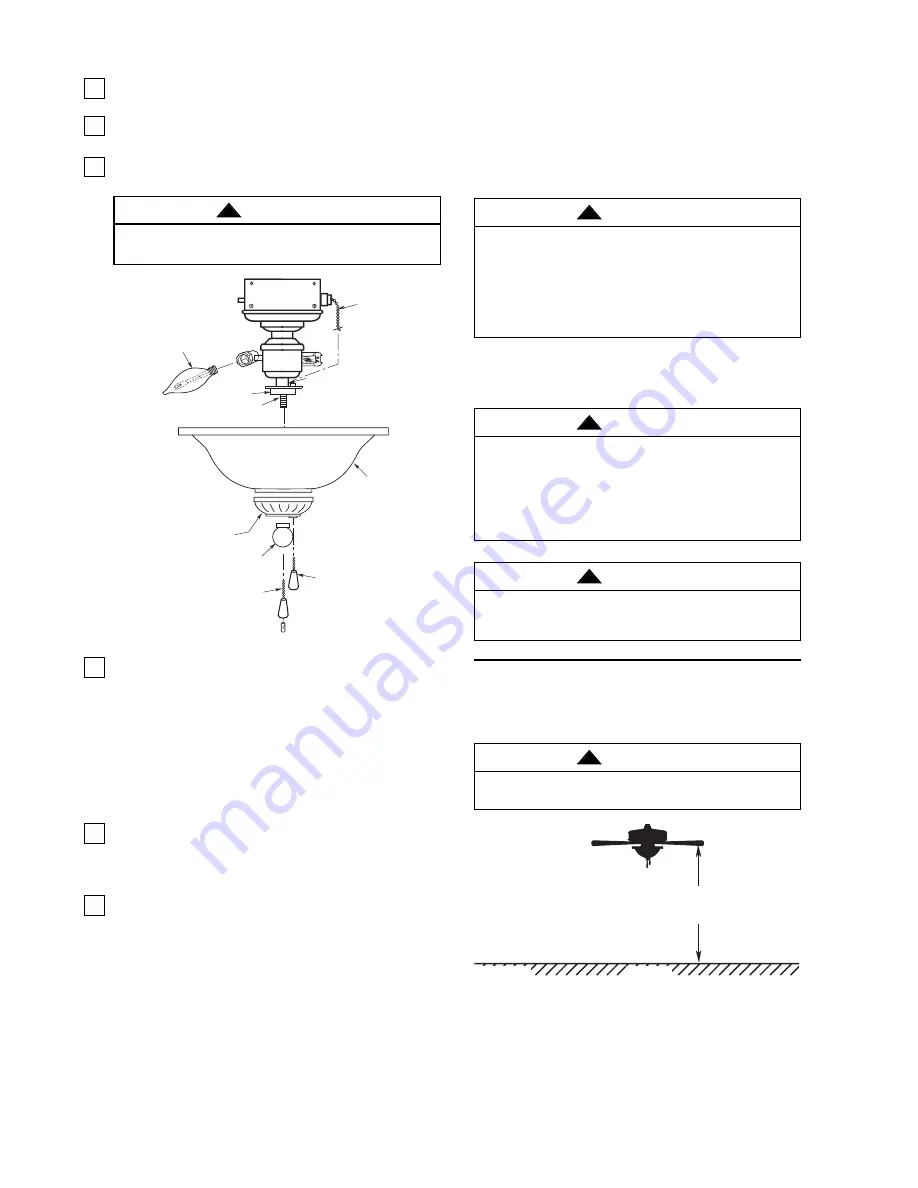

Install two 60-watt (maximum) candelabra base

light bulbs into the light fitter sockets (Figure 8).

16.

Remove the finial nut and outer bowl cap from the

light fitter (Figure 8).

17.

Pass the fan switch chain through the cut-slotted

hole in the bowl cap (Figure 8).

To avoid possible fire hazard, do not exceed wattage

indicated on the fitter.

WARNING

!

THREADED NIPPLE

BOWL CAP

LIGHT FITTER

OUTER BOWL

CAP

GLASS BOWL

60-WATT

CANDELABRA

BASE BULBS (2)

FINIAL NUT

FAN SWITCH

CHAIN

PENDANTS (2)

LIGHT SWITCH

CHAIN

Figure 8

18.

Position the glass bowl over the threaded nipple

and seat bowl on bowl cap (Figure 16). Pass the

fan pull chain through the bushing in the outer

bowl cap and install the cap on the threaded

nipple. Install nut finial finger tight.

CAUTION

Be sure that the fan switch chain does not make

contact with the light bulbs. If necessary

reposition the light fitter to avoid the fan switch

chain from touching the light bulbs.

19.

Install pendants onto light fixture chain and fan

switch chain using couplings provided.

NOTE: It is advisable to periodically check the

tightness of the finial.

20.

You have now completed the assembly of your

new ceiling fan. You can now proceed with

hanging and wiring your fan.

The fan must be hung with at least 7' of clearance

from floor to blades (Figure 9).

WARNING

!

FLOOR

7'

MIN.

Figure 9

Installing The

Hanger Bracket