2

CASH VALVE™

A-360 AND A-361 PRESSURE REGULATORS

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

MAINTENANCE INSTRUCTIONS

The following procedures are provided for

servicing the recommended spare parts for the

Types A-360 and A-361 regulators. Repair parts

can easily be installed without removing the

regulator from the line.

CAUTION

Before attempting to replace any spare parts be

sure to shut off all pressure connections to the

valve. With the valve closed, however, system

pressure could still be locked between the shut

off valve and the inlet and/or outlet sides of the

regulator. Before proceeding with any valve

service be certain to relieve the pressure from

BOTH sides of the regulator.

Servicing Diaphragm(s), Top O-Ring, and

Pressure Spring

1. Loosen the lock nut and turn the adjusting

screw counterclockwise until the pressure

spring is no longer under tension. When

reassembling, run the adjusting screw down

until the lock nut almost touches the spring

chamber. This will give you approximately

the same set as before disassembly.

2. Remove the spring chamber from the

body. When reassembling, torque to

50-60 ft-lbs (67.8-81.3 N•m).

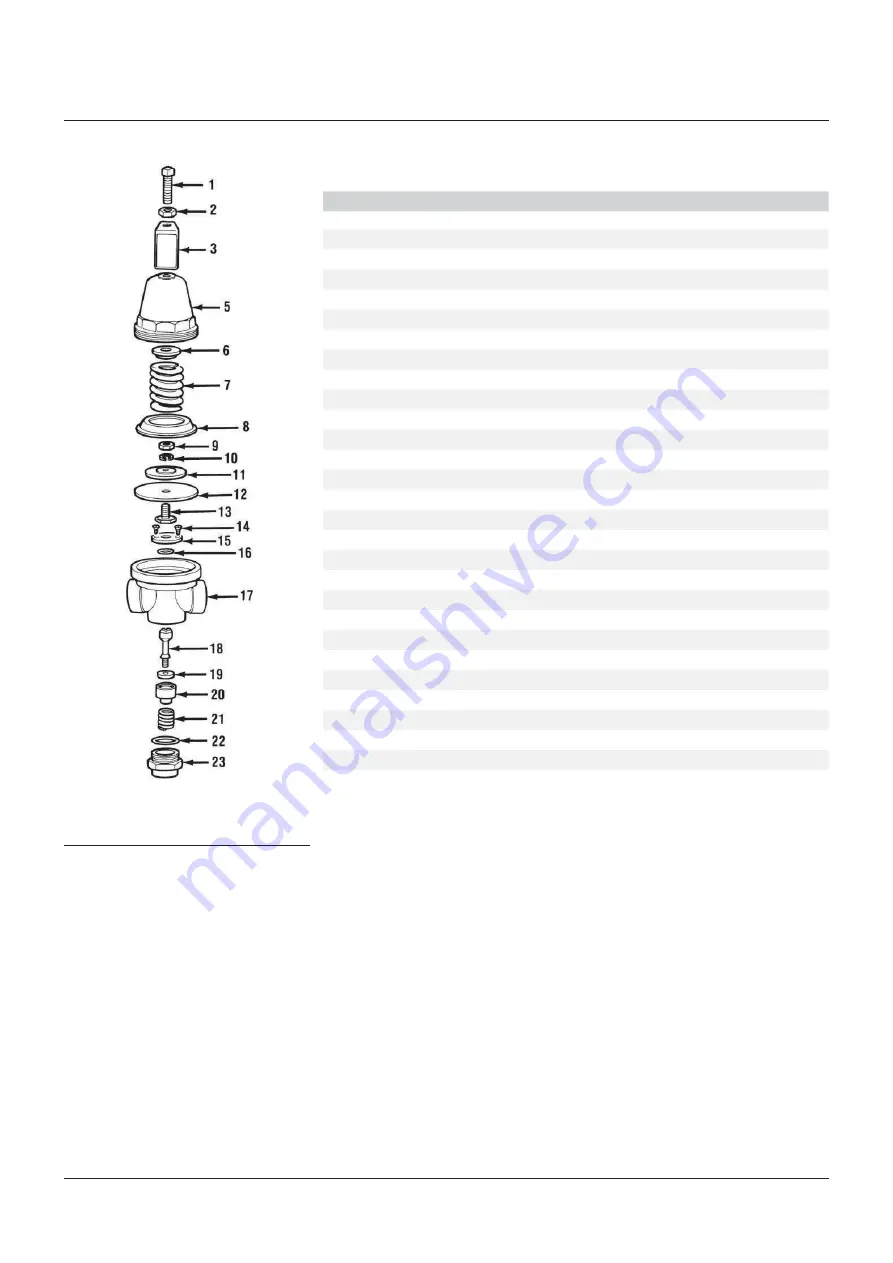

REPAIR PARTS INFORMATION

Refer to the regulator exploded view for parts identification.

Item No. Description

Material

Quantity

1

Adjusting Screw (Square Head)

Steel

1

1

+

Adjusting Screw (T-Handle) Set

Brass

1

2

Lock Nut (Hex for Sq. Hd. Screw)

Steel

1

2+

Lock Nut (Hex for T-Handle)

Steel

1

2+

Lock Nut (Wing for Panel Mounting)

Steel

1

3

Identification Tag

Aluminum

1

4

Bushing (for Panel Mounting only)

Brass

1

5

Spring Chamber (for Sq. Hd. Screw)

Brass

1

5+

Spring Chamber (for T-Handle)

Brass

1

5+

Spring Chamber (for Panel Mounting)

Brass

1

6

Spring Button

Brass

1

7

Pressure Spring (see Ranges chart)

Stainless steel

1

8

Diaphragm Stop

Brass

1

9

Pressure Plate Nut

Steel

1

10

Lock Washer

Steel

1

11

Pressure Plate

Brass

1

12*

Diaphragm

Neoprene

1

13

Pusher Post Button (A-360, A-361)

Brass

1

14

Retainer Plate Screws

Brass

2

15

Retainer Plate

Brass

1

16*

O-Ring (Top)

Buna-N

(1)

1

17

Body (A-360 2 Way)

Brass

1

17+

Body (A-361 4 Way)

Brass

1

18*

Pusher Post (A-360, A-361)

Stainless steel

1

19*

Seat Disk

Buna-N

(1)

1

20*

Piston

Brass

1

21

Piston Spring

Stainless steel

1

22*

O-Ring (Bottom)

Buna-N

(1)

1

23

Bottom Plug

Brass

1

* Recommended Spare Parts

+ Not pictured

1 Depending on construction. Seat Material also available in Viton and Teflon. Seat Material

selection determines O-ring material.

3. Remove the spring button, pressure

spring, diaphragm stop, and diaphragm

subassembly. When reassembling,

torque diaphragm nut to approximately

75 in-lbs (8.48 N•m).

4. If the top o-ring is to be serviced, remove

the two retainer plate screws and remove

the retainer plate and top o-ring. Lubricate

top o-ring with Dow Corning Molykote 111 or

equivalent before installing.

5. Inspect all parts for wear and damage and

replace if necessary. Reassemble parts

in reverse order. DO NOT OVERTIGHTEN.

Follow the Operation Instructions to reset

the delivery pressure.