3

CASH VALVE™

A-360 AND A-361 PRESSURE REGULATORS

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

SPECIFICATIONS

Each Type A-360 or A-361 pressure regulator

is equipped with a pressure spring selected to

provide the desired outlet or reduced pressure

setting. The range of adjustment or satisfactory

"working range" of individual springs is shown

above for each valve size. Every regulator has

the "set" pressure and range of adjustment

stamped on a tag fastened to the valve. The

ranges shown below are recommended for

best performance.

Size,

in. (mm.)

Range of Adjustment, psi (bar)

¼

(6.35)

0-5

(0-0.35)

2-35

(0.14-2.41)

20-70

(1.38-4.83)

60-125

(4.14-8.62)

75-200

(5.17-13.8)

100-250

(6.89-17.2)

⅜

(9.53)

0-5

(0-0.35)

2-35

(0.14-2.41)

20-70

(1.38-4.83)

60-125

(4.14-8.62)

75-200

(5.17-13.8)

100-250

(6.89-17.2)

½

(12.7)

0-5

(0-0.35)

2-25

(0.14-1.72)

20-60

(1.38-4.14)

40-80

(2.76-5.52)

75-125

(5.17-8.62)

100-250

(6.89-17.2)

SPRING RANGES

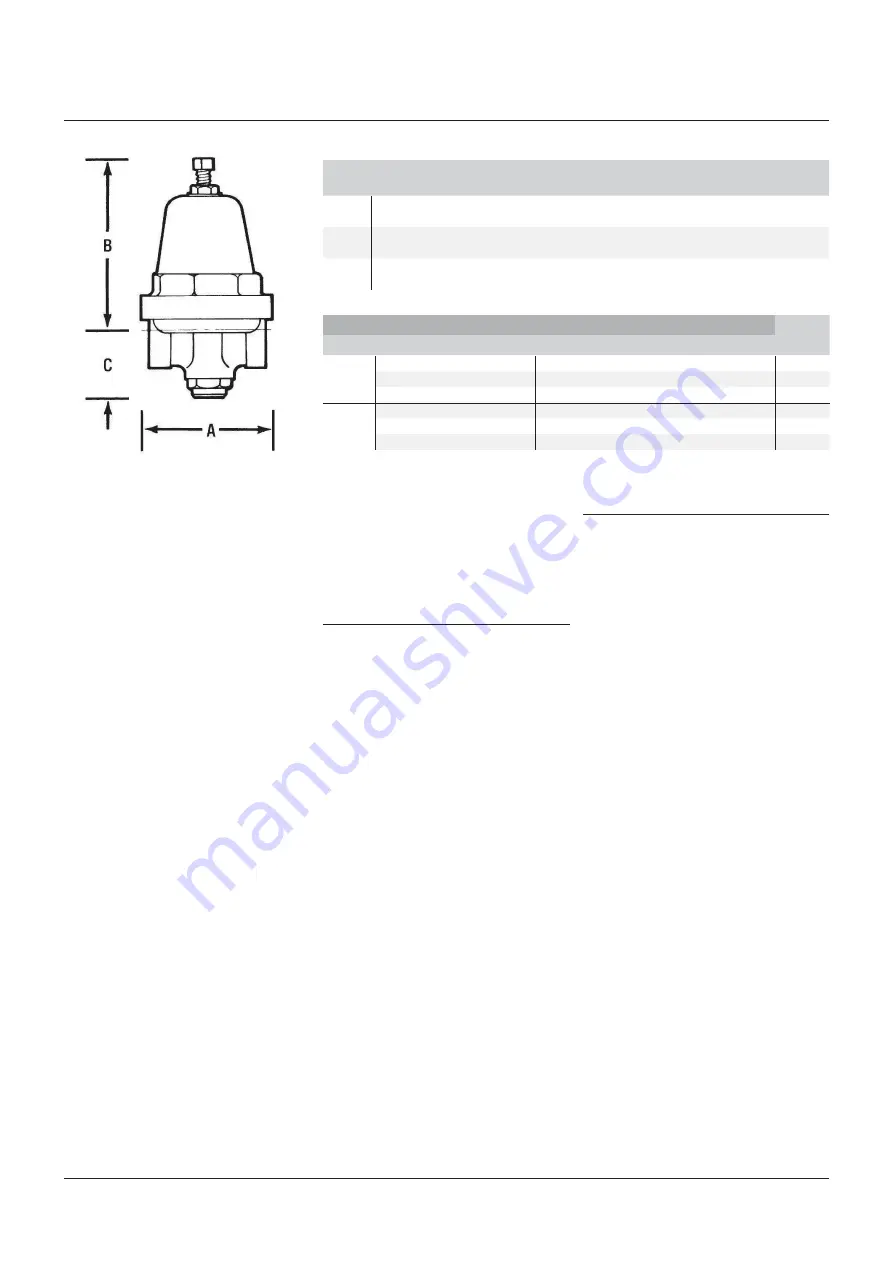

DIMENSIONS

Description

Dimensions, in. (mm)

Ship. Wt.,

lbs. (kg)

Type

Size, in. (mm)

Style

A

B

C

A-360

¼ (6.35)

2-Way

2½ (64)

4½ (114)

1⅛ (29)

2 (0.9)

⅜ (9.53)

2-Way

2½ (64)

4½ (114)

1⅛ (29)

2 (0.9)

½ (12.7)

2-Way

2⅞ (73)

4½ (114)

1⅝ (41)

2½ (1.1)

A-361

¼ (6.35)

4-Way

2½ (64)

4½ (114)

1⅛ (29)

2⅛ (1.0)

⅜ (9.53)

4-Way

2½ (64)

4½ (114)

1⅛ (29)

2⅛ (1.0)

½ (12.7)

4-Way

2⅞ (73)

4½ (114)

1⅝ (41)

2⅝ (1.2)

VCIOM-14994-EN © 2020, 2022 Emerson Electric Co. All rights reserved 01/22. Cash Valve is a mark owned by one of the companies in the Emerson Automation

Solutions business unit of Emerson Electric Co. The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their

prospective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed

by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time

without notice.

Emerson Electric Co. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance

of any Emerson Electric Co. product remains solely with the purchaser.

HOW TO ORDER

To order repair parts, refer to the exploded view

of the Type A-360 to identify the part required.

When ordering, please use the part names

listed and provide the valve serial number

stated on the identification tag. Also state the

following: "Repair Parts for A-360 or A361"

and provide:

1. Valve size

2. Service (air, water, oil, non-corrosive liquids,

or gas)

3. Inlet pressure

4. Outlet or delivery pressure range and setting

5. Part description

6. Quantity of each part

7. Valve assembly or serial number stated

on the metal identification tag under the

adjusting screw lock nut.

Servicing the Seat Disk and Bottom O-Ring

1. Loosen the lock nut and turn the adjusting

screw counterclockwise until the pressure

spring is no longer under tension. When

reassembling, run the adjusting screw down

until the lock nut almost touches the spring

chamber. This will give you approximately

the same set as before disassembly.

2. Remove the bottom plug. Take care, as

the bottom plug is under slight tension

as a result of the piston spring acting

against the bottom plug. Remove the

piston subassembly, piston spring, and

bottom o-ring. Lubricate bottom o-ring with

Dow Corning Molykote 111 or equivalent

before installing. Unscrew the pusher

post from the piston to remove the seat

disk. Do not lubricate the seat disk. When

reassembling, ensure that the pusher post

is seated completely against the seat disk;

torque the bottom plug to approximately

10 ft-lbs (13.6 N•m).

3. Remove any debris from the valve body.

4. Inspect all parts for wear and damage and

replace if necessary.

5. Reassemble the valve in reverse order. DO

NOT OVERTIGHTEN. Follow the Operation

Instructions to reset the delivery pressure.