9

18. Screw in two 60-watt (maximum)

candelabra bulbs in the light fitter

sockets (Figure 12). Bulbs not

supplied.

19. Place the lower glass into the light

fitter, aligning the three flat areas on

the lower glass flange with the three

tabs on the light fitter (Figure 13).

Then turn the lower glass clockwise

until the glass stops turning.

20. Your ceiling fan is now installed and

wired to be controlled by your SW101

Fan/Light Wall Control.

FLAT AREAS (3)

LOWER

GLASS

TABS (3)

LIGHT FITTER

Figure 13

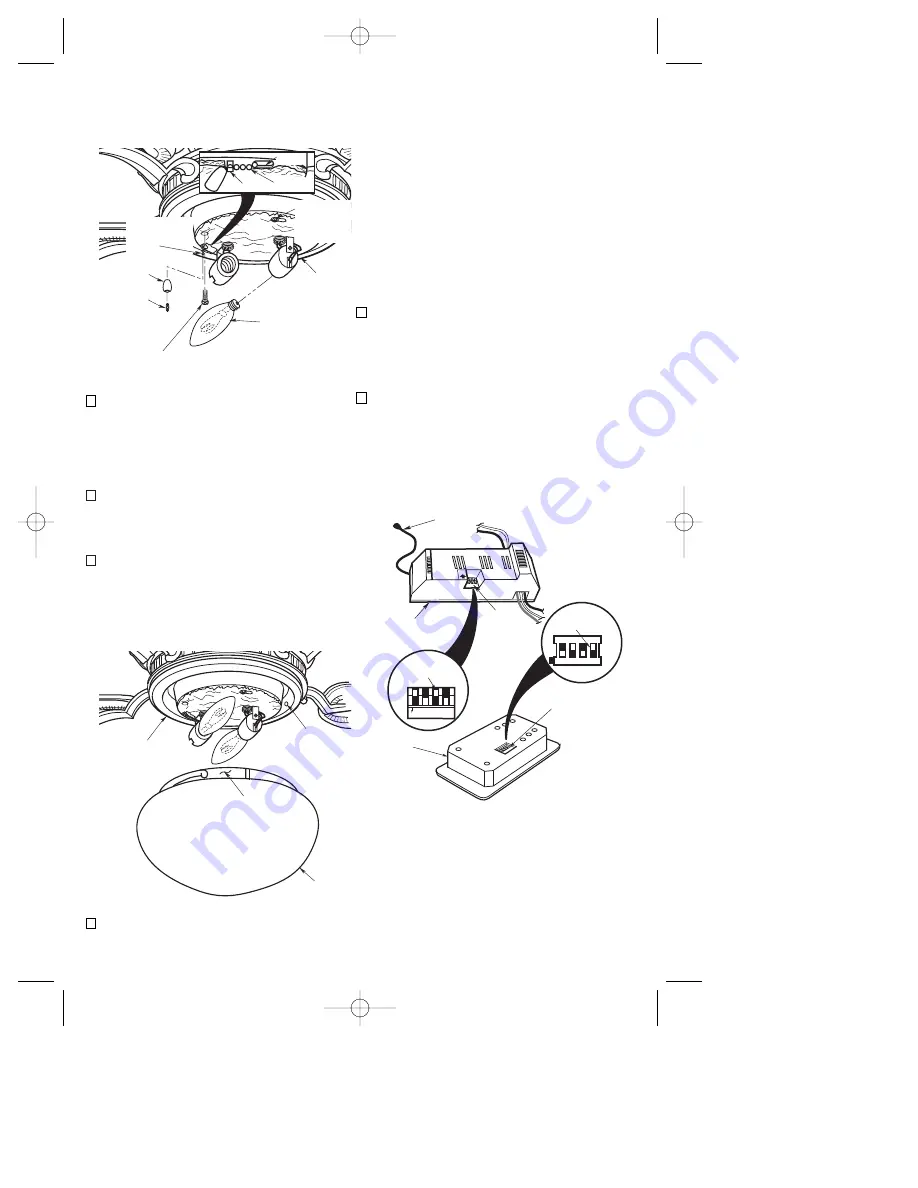

Setting Operating

Frequency of Wall

Control and Receiver

(Figure 14)

Your wall control and receiver have code

switches which must be set in one of 16

possible code combinations. The four

levers (numbered 1, 2, 3, and 4) on the

switches are factory-set in the ON (up)

position. Change the switch settings as

follows:

1. Slide the four switch levers in the wall

control to your choice of ON (up) or

down positions. Use a ball-point pen or

small screwdriver and slide the levers

firmly up or down.

2. In the receiver, slide the four switch

levers to the same positions as set in

the wall control. Make sure the levers

on both switches are in the same

positions, otherwise the fan will not

operate.

Figure 14

WALL CONTROL

LEVERS

ON

1

2

3

4

RECEIVER

SWITCH LEVERS

ON

1

2

3

4

CODE

SWITCH

ANTENNA WIRE

1 2 3 4

ON

RECEIVER

CODE

SWITCH

WALL

CONTROL

LIGHT

FITTER

TIGHTEN

THREE PAN

HEAD

SCREWS

60-WATT

(MAXIMUM)

CANDELABRA

BULBS (2)

INSTALL PAN HEAD SCREW

WITH LOCKWASHER

PENDANT

COUPLING

REVERSING

SWITCH PULL

CHAIN

CLIP

CHAIN

HOLE

Figure 12

17. Slip the reversing switch chain

through the pendant (supplied), then

secure the pendant by snapping the

coupling onto the end of the chain

(Figure 12). Hook the chain in the clip

as shown in Figure 12 insert.

NOTE: Make sure that the lockwashers

are positioned between the screw head

and the light fitter.

BP7315 Florissant 3/7/06 8:42 AM Page 9