7

PARTIALLY

ASSEMBLED

FAN

SOLID

STYROFOAM

FACING OUT

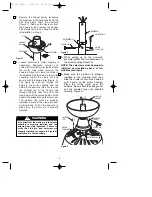

6" - 8"

GAP

Figure 5

CEILING

COVER

PIN

DOWNROD

HANGER BALL

SETSCREW

Figure 4

SLIDE FAN BLADE

INTO CENTER SLOT

FAN BLADE

M5 x 12mm WASHER

HEAD BLADE SCREWS

(3 per blade)

CENTER SLOT

FAN

HOUSING

Figure 6

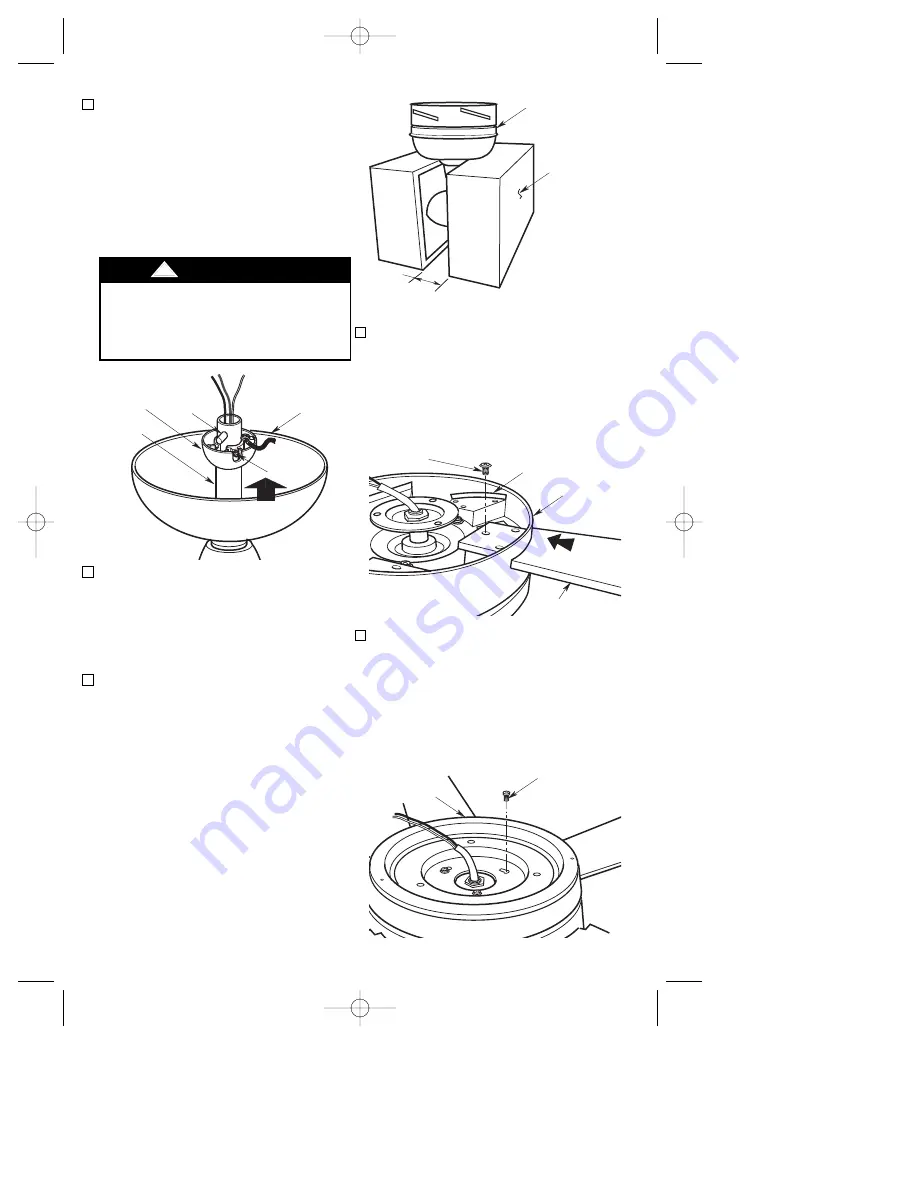

M4 x 10mm

SERRATED HEAD

SCREW (3)

LOWER

HOUSING

Figure 7

It is critical that the pin in the hanger ball

is properly installed and the setscrew

securely tightened. Failure to verify that

the pin and setscrew are properly

installed could result in the fan falling.

!

WARNING

5. Reinstall the hanger ball (Figure 4) on the

downrod as follows. Route the motor

leads through the downrod. Position the

pin through the two holes in the downrod

and align the ball so the pin is captured in

the groove in the top of the hanger ball.

Pull the hanger ball up tight against the

pin and securely tighten the setscrew in

the hanger ball. A loose setscrew could

create fan wobble.

6. The fan comes with blue, black and

white leads that are 80” long. Before

installing fan, measure up approx-

imately 6 to 9-inches above top of

hanger ball/downrod assembly. Cut off

excess leads and strip back insulation

1/2-inch from end of leads.

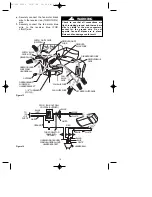

7. Turn fan motor assembly upside down

in preparation for mounting fan blades.

Position the top and bottom halves of

the styrofoam packaging on end, with

solid styrofoam facing outward. Set

side-by-side on the floor with a six to

eight-inch gap between the halves

(Figure 5). Carefully place the partially

assembled ceiling fan on the styrofoam

halves, with the hanger ball/downrod

assembly positioned in the gap and the

fan motor assembly resting on top of

the styrofoam ends.

8. Slide blade through center slot in fan

housing. Mount blade to fan housing

using three M5 x 12mm washer head

blade screws (Figure 6).

9. Position the lower housing onto the fan

motor assembly, aligning each of the

the three holes. Attach the lower

housing to the fan motor assembly

using three M4 x 10mm serrated head

screws. Rotate the lower housing to

securely tighten by engaging the

screws in the two key hole slots

(Figure 7).

NOTE: Take care not to scratch fan

housing when installing blades.

BP7332 CF930 10/27/06 10:05 AM Page 7