118

ADVANCED USER GUIDE

IP66/Nema 4X variable speed drive

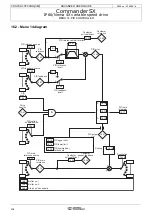

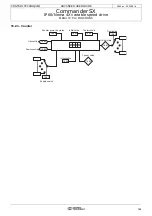

MENU 14: PID CONTROLLER

CONTROL TECHNIQUES

3854 en - 03.2008 / b

: PID output scaling

Adjustment range : 0 to 2.50

Factory setting

: 1.00

This parameter is used to scale the PID output before it is

added to the main reference.

The sum of both references is automatically scaled according

to the adjustment range of the parameter to which it is

addressed.

: PID output destination

Adjustment range :

0.00

to

21.51

Factory setting

:

0.00

Used to define to which parameter the PID output is

addressed.

Only unprotected non-bit parameters can be assigned.

If an unsuitable parameter is assigned, the output will not be

sent to any address.

If the PID output is supposed to affect the speed, it is

advisable to address it to a preset reference.

: PID hold integrator

Adjustment range : 0 or 1

Factory setting

: 0

0 (Disabled) (OFF): Integration is carried out normally

when the PID loop is activated.

1 (Enabled) (On): The value of the integrator is frozen and

remains at this value until

14.17

goes back to 0.

In both cases, when the PID loop is deactivated, the value of

the integrator is reset to 0.

: PID symmetrical limit enable

Adjustment range : 0 or 1

Factory setting

: 0

0 (Disabled) (OFF): Inactive.

1 (Enabled) (On):

14.13

and

14.14

take the same value

and it is

14.13

which is effective.

: PID main reference

Adjustment range : ± 100.0%

This parameter indicates the value of the main reference.

: PID reference

Adjustment range : ± 100.0%

This parameter indicates the value of the PID reference.

: PID feedback

Adjustment range : ± 100.0%

This parameter indicates the value of the PID feedback.

: PID error

Adjustment range : ± 100.0%

This parameter indicates the error between the main

reference and the feedback.

to

: Not used

: Buffer no. 1

Adjustment range : ± 100.00%

Factory setting

: 0

This parameter is used to assign an analog input to the PID

reference or feedback.

: Buffer no. 2

Adjustment range : ± 100.00%

Factory setting

: 0

This parameter is used to assign an analog input to the PID

reference or feedback.

: Customer unit coefficient

Adjustment range : 0 to 30

Factory setting

: 1

This parameter is a multiplication coefficient allowing the PID

reference and PID feedback to be displayed as a customer

value (

14.54

and

14.55

).

: Customer reference value

Adjustment range : ± 32000

This parameter indicates the value of the PID reference in

customer units (scaled using

14.53

).

: Customer feedback value

Adjustment range : ± 32000

This parameter indicates the value of the PID feedback in

customer units (scaled using

14.53

).

: Stop on Vmin enable

Adjustment range : 0 or 1

Factory setting

: 0

0 (Disabled) (OFF)

1 (Enabled) (On)

This parameter is used to enable the automatic run/stop

function when preset configuration

05

=

11.46

= 8.

During operation, if

14.56

= 1 and the flow rate is at minimum

(min. speed) for a time period set by

16.15

(parameter set

automatically when the configuration is enabled), the pump

stops.

WARNING:

This stop on Vmin function is only active when using the

"PUMP" preset configuration. When not using this

configuration,

14.56

is a simple "bit" parameter (buffer

block).

14.15

14.16

14.17

14.18

14.19

14.20

14.21

14.22

14.23

14.50

14.51

14.52

14.53

14.54

14.55

14.56