D6.3.4/0715-0716/E

11

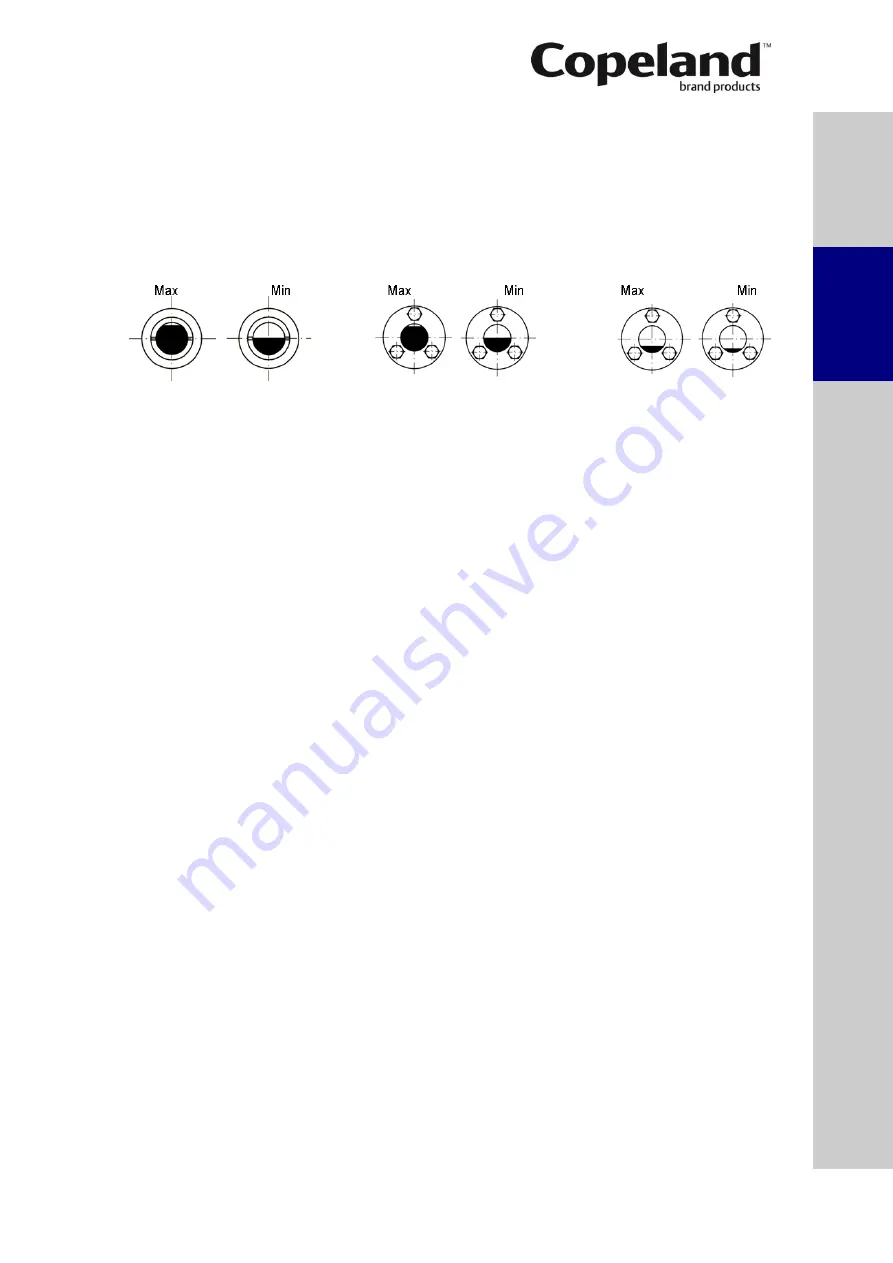

2.6.11 Oil level

All compressors are delivered with sufficient oil for normal operation (see oil quantities in Select).

The optimum oil level should be checked by operating the compressor until the system is stable

and then comparing the sight glass reading with the appropriate diagram below. The level can

also be checked within 10 sec. of compressor shut-down. For 4- to 8-cylinder compressors a

higher oil level may be accepted when an oil regulator is in use because the oil separator will

reduce excessive oil circulation.

DK, DL

D2, D3

D4, D6, D8

K, L

2D, 3D

8D

Figure 4

2.6.12 Oil separation & management for booster applications

In direct-stage refrigeration systems, oil carried over from each compressor may accumulate in

one of the compressors in series resulting in a lack of lubrication for the others. To ensure each

compressor has the correct amount of oil returned, Emerson Climate Technologies recommends

the use of a highly efficient cyclone or coalescent type oil separator with an oil management

system. The oil separator shall be installed in the discharge line of the high stage compressor. It

will separate the oil from the discharge gas and pass it to an oil reservoir. The oil will then pass

from the oil reservoir through the oil management system to each individual compressor

ensuring full lubrication and extended compressor life and reliability.

2.6.13 R22 Low temperature applications using D2SA

–450/X Air & D2SC–550/X Air

compressors

R22 low temperature applications require suction superheat limitations for both the D2S and

D3S compressors (refer to the operating envelope in Copeland brand products Select software

for details). With the D2S range this is achieved by repositioning the suction valve, moving it

from the motor cover end to the compressor body. This changes the compressor from a suction

gas-cooled model to an air-

cooled model. We now have the “D2SA–45X Air”, “D2SA–450 Air”,

“D2SC–55X Air” and “D2SC–550 Air” air-cooled compressors. The D2SK–65X and D2SK–650

models cannot be run at low temperatures using R22. The smallest D3SC model should be used

for these applications (almost the same capacity at low temperature as the D2SK).

S

afet

y

in

struct

ion

s

P

ro

d

u

ct

d

es

cr

ipt

ion

Inst

all

atio

n

E

lec

tr

ica

l

c

o

n

n

ec

tion

S

tar

ting

up

&

o

p

er

atio

n

Ma

int

enan

c

e &

repai

r

T

ro

u

b

le

-

sho

o

ting

Dismant

ling

&

d

ispo

sa

l