20

D6.3.4/0715-0716/E

4.7

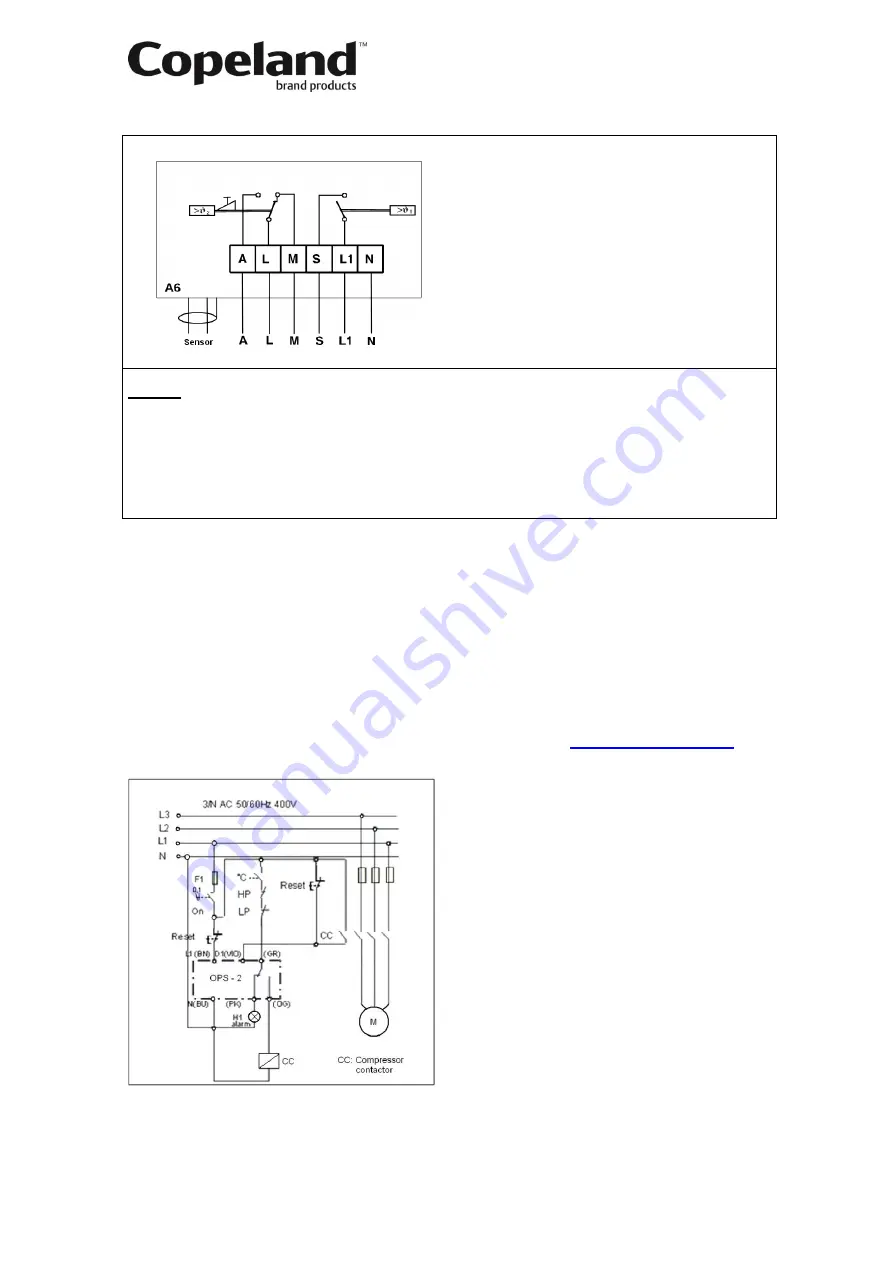

Demand Cooling

Legend

A

......... Alarm connection

θ

1

........ Temperature control device for

L

......... Control voltage connection

energising the injection valve

M

......... Control circuit

θ

2

........ Temperature control device for

S

......... Injection valve connection

switching off the compressor

L1

....... Voltage connection

A6

........ Demand Cooling module

N

......... Neutral connection

Figure 18

4.8

Oil pressure control

4.8.1 Oil pressure switch (OPS2)

Where there is a 5-wire cable connection between the electrical control panel and the

compressor terminal box to the OPS module, the same wires can be applied to the OPS2 which

will give the functions of an OPS1 module.

To obtain use of all of the features of the OPS2 a 7-wire cable between the electrical control

cabinet and the compressor terminal box should be used. Wiring diagrams for both the OPS1

and OPS2 are shown in Technical Information D7.8.3

“DWM Copeland™ Semi-hermetic

Compressor Oil Pressure Differential Switch OPS2” available at

. The

wiring diagram relates to an option using a 7-wire cable.

Wiring:

Brown (BN) = Power supply input

Violet (VIO) = Running signal from the

compressor

Grey (GR) = Input changeover contact from the

daisy chain

Orange (OG) = Output changeover contact

linked to the compressor contactor

Pink (PK) = Output changeover contact linked to

the alarm

Blue (BU) = Power supply output

Figure 19

NOTE:

Where a 5- or 7-wire cable is stated a 4- or 6-wire cable is required. In some

countries only a 5- or 7-wire cable is available. See more information about OPS2 in

Technical Information

D7.8.3 “DWM Copeland™ Semi-hermetic Compressor Oil Pressure

Differential S

witch OPS2”.