AGL_Stream_ST_4MTL_4MSL_E_Rev01

25

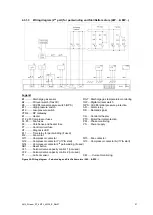

4.3.3.2

Wiring diagrams for Star/Delta motors (EW

…)

Legend

A4 ....... Sensor module

L1 ........ Current transducer CoreSense

A5 ....... Compressor terminal box

M21 ..... Fan motor / condenser

F6 ....... Fuse for control circuit

R2 ........ Crankcase heater

F7 ....... Fuse for control circuit

Y7 ........ Solenoid valve pumpdown

F8 ....... Fuse for control circuit

Y21 ...... Solenoid valve

F10 ..... Thermal protection switch M21

Y22 ...... Solenoid valve

K1 ....... Contactor M1

S1 ........ Thermistor chain motor temperature

K2 ....... Contactor M1 Y-connection

S2 ........ Thermistor chain motor temperature

K3 ....... Contactor M1

Δ-connection

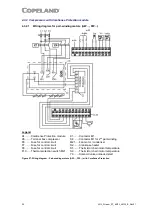

Figure 30: Wiring diagram

– Direct-On-Line (EW…) motors with CoreSense Diagnostics

NOTE: The sensor module inside the terminal box requires a separate 24 VAC power supply.