12

AGL_Stream_ST_4MTL_4MSL_E_Rev01

Figure 14: Compressor lifting

3.1.4 Installation location

Ensure the compressors are installed on a solid level base. Horizontal installation is recommended.

Temperatures around the compressor should not exceed 65 °C in order to avoid suction gas

temperature increase and malfunctioning of electronics.

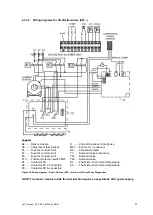

3.1.5 Mounting parts

To minimize vibration and start/stop impulses flexible mounting should be used. For this purpose,

one set of rubber mounting parts for each of the Stream models is delivered with each 4MTL* and

4MSL* compressor. The mounting kit can be used for single and parallel operation.

Figure 15: Compressor mounting parts

A compressor may be rigidly mounted, ie, without mounting parts. In this case more shock and

vibration loading will be transmitted to the frame. Use only the compressor foot for fixation and avoid

direct contact of other parts of the compressor housing with bordering components or base frame.

Unevenness in the mounting surface will have to be compensated by the rack and/or the compressor

bottom plate/feet. Excessive unevenness can result in too high mechanical stress to the system and

could damage the compressor or rack. Therefore, the flatness of the mounting location is essential.

In addition, both vibration/shock and mechanical stress to compressor can be avoided by using

rubber mounting parts.

If the installation requires a very high level of vibration absorption, additional vibration absorbers

–

available on the market

– can be fitted between the rails and the foundation.

Locknut

Washer

Rubber spacer

Body mounting foot

Rubber spacer

Rubber pad

Spacer

Screw hex head