D7.8.6/1112-0815/E

6/18

4

Physical layer

This layer defines the hardware interface to the network.

4.1

Topology

Stream with CoreSense

Diagnostics uses the “two-wire” configuration (two signal wires plus a ground). The

standard configuration will be to directly wire to the cable forming a daisy-chain.

4.1.1 Wire used

The recommended wire is shielded twisted pair (

22 AWG or

0.33 mm

2

). The shield is also used as the circuit

ground.

Figure 3: Recommended communication wire (shielded twisted pair 22AWG or 0.33 mm

2

)

4.1.2 Bus bias

All master devices must provide a means to bias the network. The recommended pull-down on the

RS485 “+” output is a 511Ω resistor, but up to a 1KΩ resistor is acceptable. The recommended pull-up resistor on

the RS485 “–“ output is a 511Ω resistor, but up to 1KΩ is acceptable. These bias resistors can either be always

enabled or they can be enabled through jumpers. The bias is applied at one point in the network.

4.1.3 Termination

All master devices must provide a 150

Ω termination resistor. The last slave in the network must have a

150

Ω resistor for termination. In this module, there is a jumper provision to enable this termination. The jumper is

located between positions 1-

2 at “JP3” (see

Figure 4

). The last CoreSense module in the network shall be

populated with a header on this jumper. For the other CoreSense modules in the network, this jumper needs not be

populated.

4.2

Data signalling rates

4.2.1 Baud rate selection

The default communication port default settings are 19200, no parity, 8 data, 2 stop bits. The baud rate (19200 OR

9600) and parity (Even or No parity) is user-configurable through DIP-switch. The data length and stop bits are not

configurable.

4.2.2 Parity selection

Emerson Climate Technologies Modbus communication parity is user-configurable (Even or No parity).

DIP-switch Nr. 8 On

Even.

DIP-switch Nr. 8 Off

No parity (default setting).

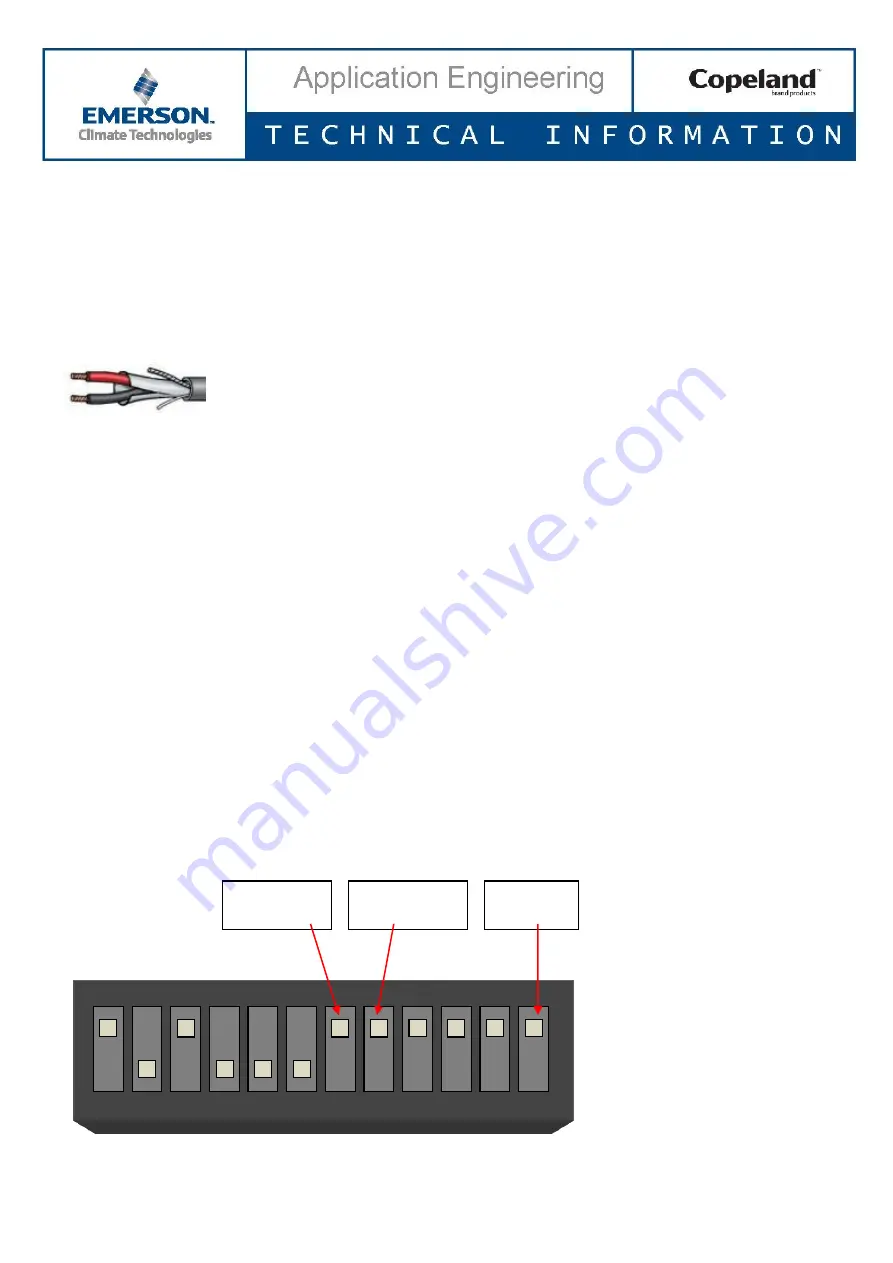

Figure 4: Baud rate and parity selection through 12 DIP-switches

ON

1

2

3

4

5

6

7

8

9

10

11

12

Baud Rate selection

On: 9600

Off: 19200 (default)

Parity selection

On: Even

Off: no Parity (default)

Inverter mode

On: with VFD

Off: without VFD