C6.1.11/0718-0619/E

33

2.13 Oil level monitoring device OW5 TraxOil

The compressor in the Copeland EazyCool CO

2

refrigeration unit is equipped with an OW5 TraxOil

oil level monitoring system. This device is intended to prevent the compressor from operating with

insufficient oil. The OW5 uses a hall sensor to measure the oil level. Unaffected by foaming oil or

light, a magnetic float changes its position according to the oil level. The hall sensor converts the

magnetic field changes into an equivalent signal, which is used by the integrated electronic controller

to monitor and display the actual oil level with LEDs.

In case of low oil level and after a delay time of 120 seconds the OW5 will generate an alarm which

will make the unit controller stop the compressor immediately.

This alarm can be displayed on the Visograph like any other alarm of the unit.

Figure 46

below depicts the sight glass level control zones.

Table 18

describes the LED code legend.

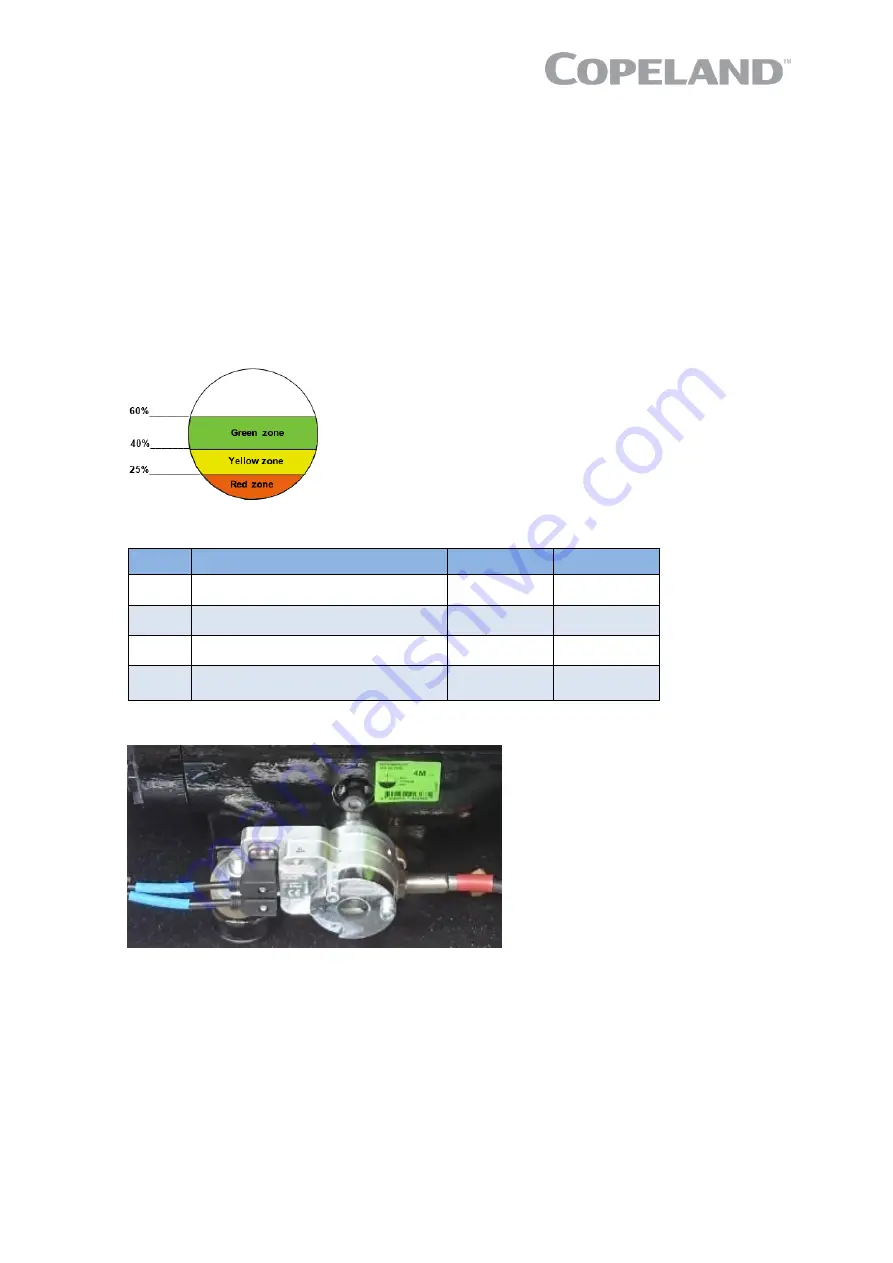

Figure 47

shows the OW5 TraxOil mounted on the compressor.

Figure 46: Sight glass level control zones

LED’s

Status

Function

Alarm

•

Oil level in green zone (60 - 40%)

OK

•

•

Oil level in green zone (60 - 40%)

OK

•

Oil level in yellow zone (40 - 25%)

Warning

•

Oil level in red zone (25 - 0%)

Alarm

Yes, delay

20 to 120 sec

Table 18: LED code legend

Figure 47: OW5 TraxOil mounted on the compressor

Summary of Contents for Copeland EazyCool OME-4MTL-09X

Page 1: ...Copeland Eazycool CO2 Refrigeration Units Application Guidelines ...

Page 5: ......

Page 68: ...C6 1 11 0718 0619 E 63 ...