C6.1.11/0718-0619/E

41

4

Start-up & operation

WARNING

High pressure!

Risk of personal injury!

Always keep sufficient distance

from the pressure relief valve to avoid serious injury in the event of a sudden

pressure release.

WARNING

Hot surfaces! Burning!

Do not touch the compressor’s heads or discharge

line as their surfaces can reach high temperatures both during operation and

at standstill.

WARNING

High noise level! Risk of hearing damage!

In case of pressure release of

the pressure relief valve, a sudden, intense sound is produced which can

damage the inner ear and cause hearing loss. Wear earplugs or other

protective devices when involved in any work on or near the unit.

Before commissioning, ensure that all valves on the refrigeration unit are fully opened. Only qualified

personal and certified companies are allowed to perform installation, commissioning, service and

maintenance work.

4.1 Evacuation

IMPORTANT

The evacuation procedure is based upon achieving an actual system vacuum

standard and is NOT TIME DEPENDENT! The installation has to be

evacuated with a vacuum pump before commissioning. Proper evacuation

reduces residual moisture to 50 ppm. The installation of adequately sized

access valves at the furthest point from the compressor in the suction and

liquid lines is advisable. The system must be evacuated down to less than

3 mbar. If required break the vacuum with dry nitrogen. Pressure must be

measured using a vacuum pressure gauge on the access valves and not on

the vacuum pump. This serves to avoid incorrect measurements resulting from

the pressure gradient along the connecting lines to the pump.

IMPORTANT

Care must be taken that all components (solenoids, expansion devices,

regulators, shut off valves, etc…) in the refrigeration cycle, which separate a

part of the installation when de-energized, are manually opened to guarantee

successful evacuation in the whole piping system.

NOTE: The controller must be turned on before starting the evacuation.

NOTE: For proper evacuation, both the HPV and BPV regulating valves must be opened using

the evacuation mode in the unit controller.

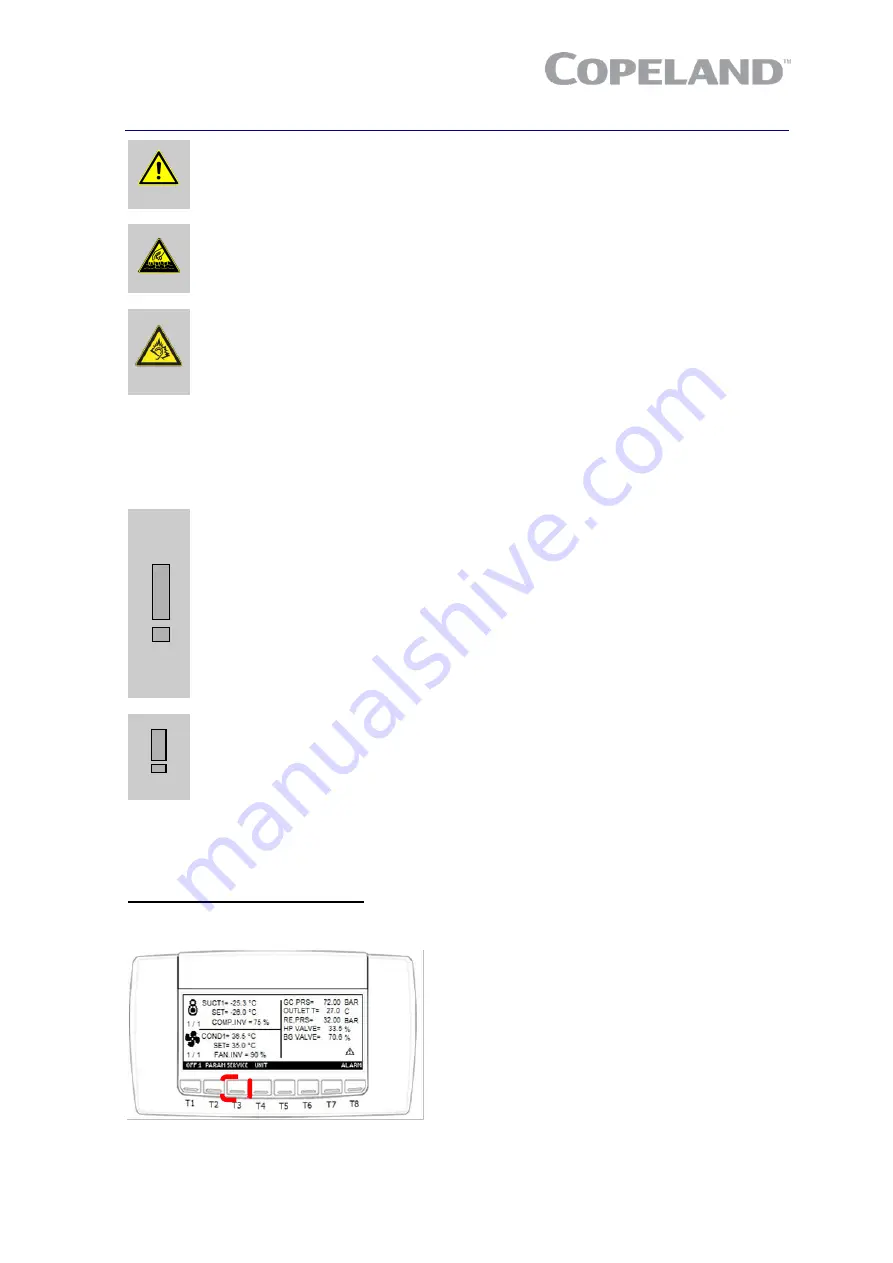

To activate the evacuation mode:

1)

Press the

SERVICE

key to enter the "Service" menu

Figure 56: Service key

2)

Use the

UP

and

DOWN

keys to select the "Evacuation mode" sub-menu

3)

Press

ENB

to enable the evacuation mode (see

Figure 57)

:

Summary of Contents for Copeland EazyCool OME-4MTL-09X

Page 1: ...Copeland Eazycool CO2 Refrigeration Units Application Guidelines ...

Page 5: ......

Page 68: ...C6 1 11 0718 0619 E 63 ...