C6.1.11/0718-0619/E

13

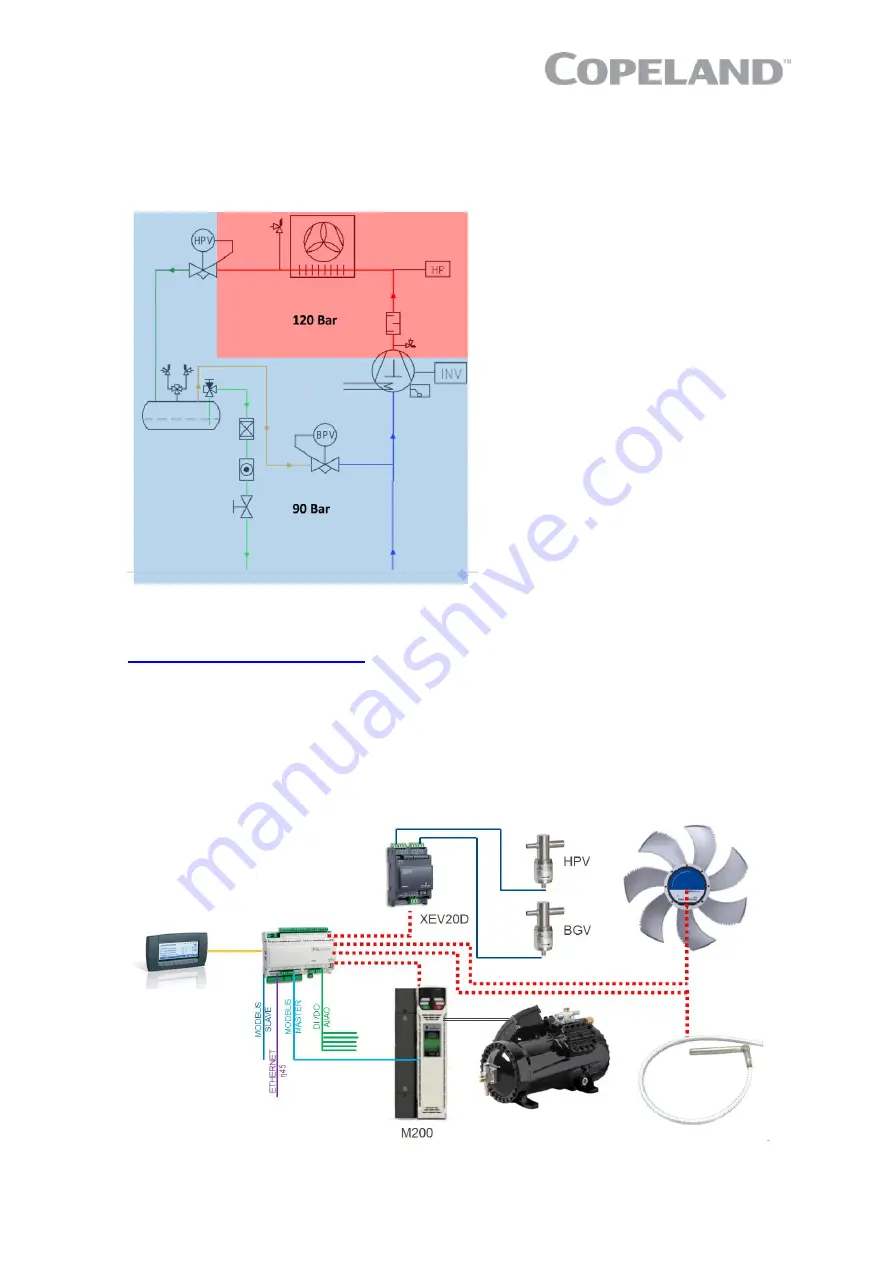

glass) to the liquid line outlet of the unit is approved for an absolute pressure of 90 bar at

standstill too.

▪

A ½" fitting is pre-installed in the suction line for an additional pressure relief valve.

▪

The area with discharge pipe, condenser/gas cooler and high-pressure regulation valve is

approved for a maximum allowable absolute pressure of 120 bar.

Figure 14: Design pressures of CO

2

unit

NOTE: The design pressure Ps is a safety-related value. The restrictions for reliable operation

of the unit are defined by the application envelope which can be found in Select software at

2.8 CO

2

Unit control

– General

Copeland EazyCool CO

2

refrigeration units are equipped with an iPro controller (IPR215D) and a

Visograph display. The iPro controller manages the compressor variable frequency drive through 0-

10V and a digital signal. It also handles the high-pressure regulation which is done by a stepper

motor valve, driven by a standard driver device, controlled by iPro through CAN BUS. The stepper

motor valve driver can operate two valves simultaneously. The controller can handle gas cooler

pressure and liquid receiver pressure in parallel.

Figure 15: CO

2

unit controller schematics

IPR215D

Visograph

Summary of Contents for Copeland EazyCool OME-4MTL-09X

Page 1: ...Copeland Eazycool CO2 Refrigeration Units Application Guidelines ...

Page 5: ......

Page 68: ...C6 1 11 0718 0619 E 63 ...