AE4-1322

© 2002 Copeland Corporation

Issued 4-2002

Printed in U.S.A.

10

Pipe runs

Pipe runs

Pipe runs

Pipe runs

Pipe runs

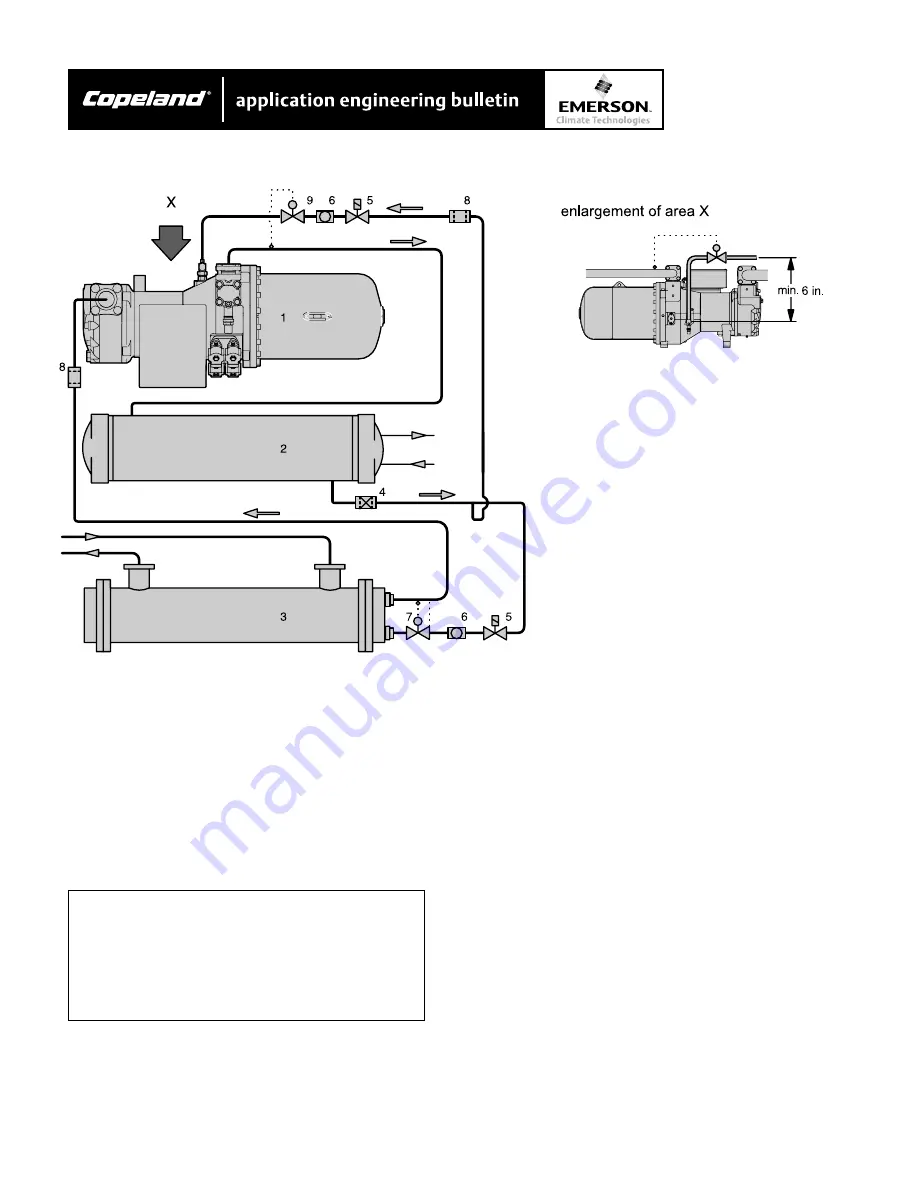

To ensure a bubble free liquid supply to the liquid

injection valve, the connection must be made on the

bottom of a horizontal section of the liquid line.

Installation of the liquid inject valve at the com-

Installation of the liquid inject valve at the com-

Installation of the liquid inject valve at the com-

Installation of the liquid inject valve at the com-

Installation of the liquid inject valve at the com-

pressor

pressor

pressor

pressor

pressor

•

Min. 6 to 8 in. above liquid injection connection

CAUTION!

CAUTION!

CAUTION!

CAUTION!

CAUTION!

V

V

V

V

Vibration fractures possible! install liquid

ibration fractures possible! install liquid

ibration fractures possible! install liquid

ibration fractures possible! install liquid

ibration fractures possible! install liquid

injection and solenoid valves with

injection and solenoid valves with

injection and solenoid valves with

injection and solenoid valves with

injection and solenoid valves with

adequate supports!

adequate supports!

adequate supports!

adequate supports!

adequate supports!

Check for vibration during operation!

Check for vibration during operation!

Check for vibration during operation!

Check for vibration during operation!

Check for vibration during operation!

Calculating the cooling capacity of the liquid

Calculating the cooling capacity of the liquid

Calculating the cooling capacity of the liquid

Calculating the cooling capacity of the liquid

Calculating the cooling capacity of the liquid

injection valve

injection valve

injection valve

injection valve

injection valve

•

With the selection software

•

Consider the most extreme conditions to be

expected during actual operation:

- min. evaporating temperature

- max. suction gas superheat and condensing

temperature

Further conditions for valve selection

Further conditions for valve selection

Further conditions for valve selection

Further conditions for valve selection

Further conditions for valve selection

•

Pressure at the injection point:

- R134a approximately 30 to 45 psig above

suction pressure R407C, R22 approx. 40 to

50 psig above suction pressure

- Never size the valve too large danger of

refrigerant flooding!

Additional components in the liquid line

Additional components in the liquid line

Additional components in the liquid line

Additional components in the liquid line

Additional components in the liquid line

•

Solenoid valve (energized parallel to compressor

contactor)

•

Filter dryer (if required)

•

Liquid sight glass

Figure 7

Liquid injection valve (system design)