12

C6.2.24/1014-0215/E

Copeland Scroll compressors have copper-plated

steel suction and discharge tubes. These tubes are

far more robust and less prone to leaks than copper

tubes. Due to the different thermal properties of

steel and copper, brazing procedures may have to

be changed from those commonly used.

Figure 17

shows the proper procedure for brazing

the suction and discharge lines to a scroll

compressor.

The copper-coated steel tubes on scroll compressors can be brazed in approximately the

same manner as any copper tube.

Recommended brazing materials: any silfos material is recommended, preferably with a

minimum of 5% silver. However, 0% silver is acceptable.

Be sure tube fitting inner diameter and tube outer diameter are clean prior to assembly.

Using a double-tipped torch, apply heat in area 1.

As the tube approaches brazing temperature, move the torch flame to area 2.

Heat area 2 until braze temperature is attained, moving the torch up and down and rotating

around the tube as necessary to heat the tube evenly. Add braze material to the joint while

moving the torch around the joint to flow braze material around the circumference.

After the braze material flows around the joint, move the torch to heat area 3. This will draw

the braze material down into the joint. The time spent heating area 3 should be minimal.

As with any brazed joint, overheating may be detrimental to the final result.

To disconnect:

Heat joint areas 2 and 3 slowly and uniformly until the braze material softens and the tube

can be pulled out of the fitting.

To reconnect:

Recommended brazing materials: Silfos with minimum 5% silver or silver braze used on

other compressors. Due to the different thermal properties of steel and copper, brazing

procedures may have to be changed from those commonly used.

NOTE:

Since the discharge stub contains a check valve, care must be taken not to

overheat it to prevent brazing material from flowing into it.

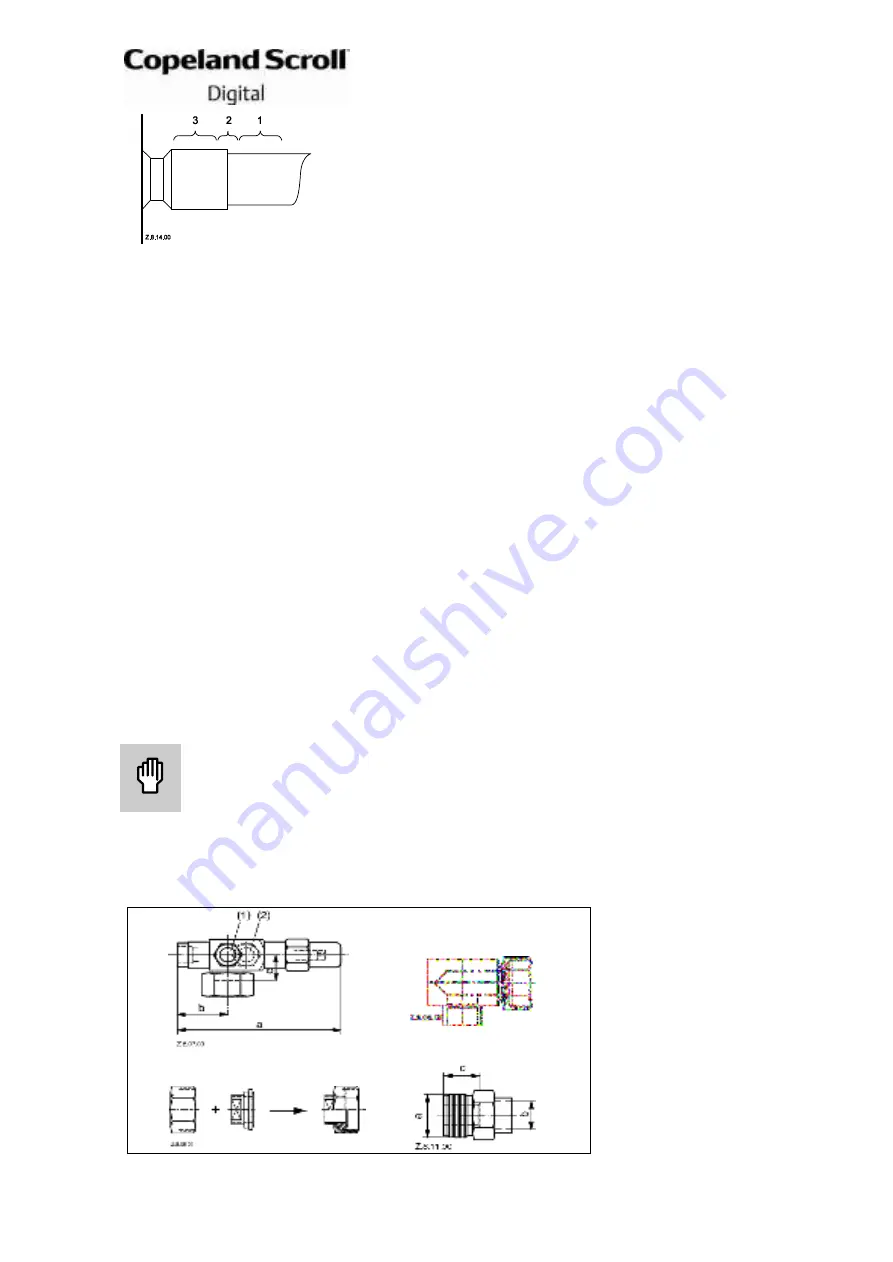

3.6 Shut-off valves and adaptors

CAUTION

Leaking system! System breakdown!

It is strongly recommended to

periodically re-torque all pipe and fixing connections to the original setting

after the system has been put into operation.

Copeland Scroll compressor models ZBD58K* to ZBD114K* and ZFD41K5E are delivered with a

discharge check valve fitted inside the discharge port and rubber plugs fitted to the suction and

discharge port as standard. There are options to fit either Rotalock valves or Rotalock adaptors,

or just make brazing connections.

Figure 15

Figure 14: Suction tube brazing