C6.2.44/0219/E

25

6.4 Lubrication and oil removal

CAUTION

Chemical reaction! Compressor destruction!

Do not mix up ester oils with

mineral oil and/or alkyl benzene when used with chlorine-free (HFC)

refrigerants.

The compressor is supplied with an initial oil charge. The standard oil charge for use with

refrigerants R450A and R513A is a polyolester (POE) lubricant Emkarate RL 32 3MAF. In the field

the oil level could be topped up with Mobil EAL Arctic 22 CC if 3MAF is not available. See

nameplate for original oil charge shown in litres. A field recharge is from 0.05 to 0.1 litre less.

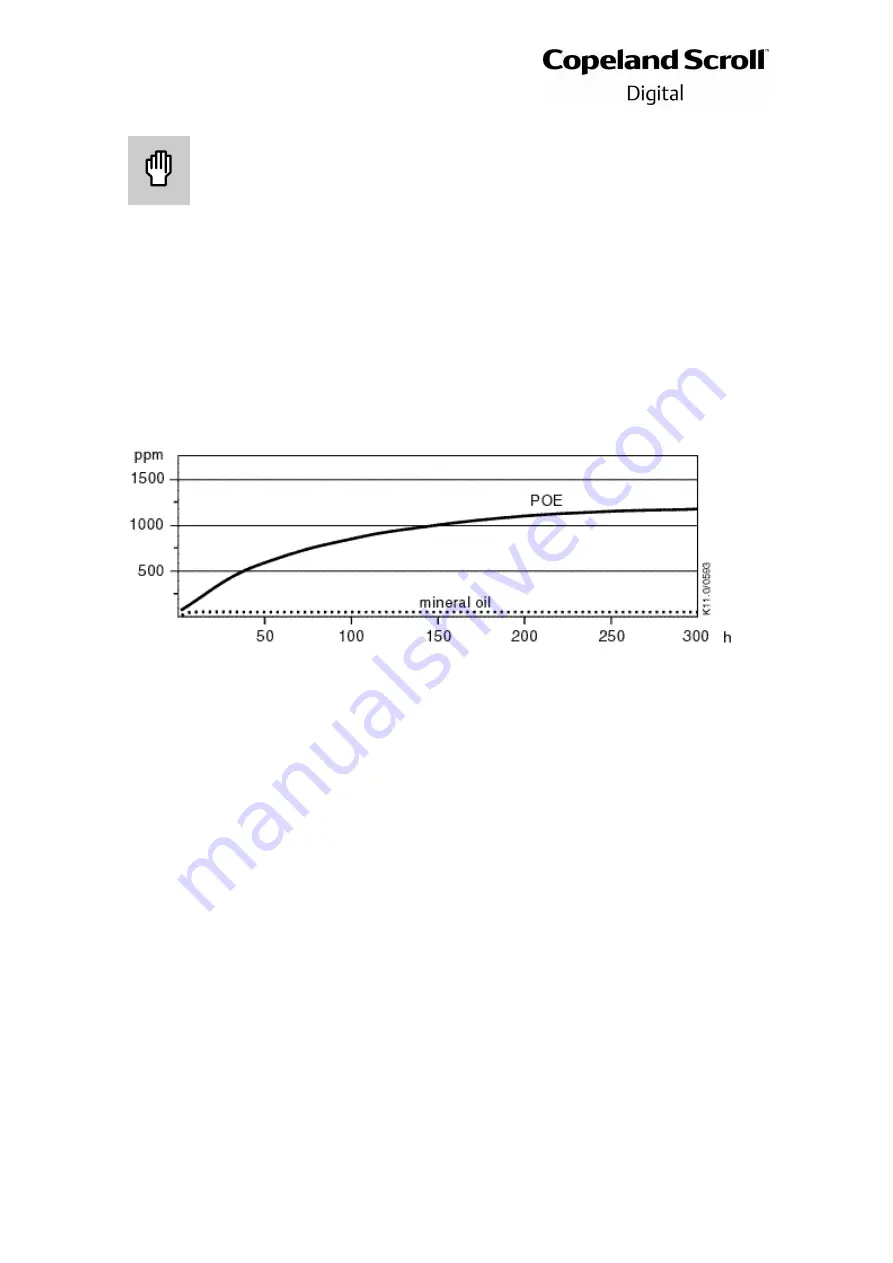

One disadvantage of POE is that it is far more hygroscopic than mineral oil (see

Figure 18

). Only

brief exposure to ambient air is needed for POE to absorb sufficient moisture to make it

unacceptable for use in a refrigeration system. Since POE holds moisture more readily than

mineral oil it is more difficult to remove it through the use of vacuum. Compressors supplied by

Emerson contain oil with low moisture content, and it may rise during the system assembling

process. Therefore, it is recommended that a properly sized filter drier is installed in all POE

systems. This will maintain the moisture level in the oil to less than 50 ppm. If oil is charged into a

system, it is recommended to use POE with a moisture content no higher than 50 ppm.

Figure 18: Absorption of moisture in ester oil in comparison to mineral oil in ppm by weight at 25°C and 50%

relative humidity (h=hours)

If the moisture content of the oil in a refrigeration system reaches unacceptably high levels,

corrosion and copper plating may occur. The system should be evacuated down to 0.3 mbar or

lower. If there is uncertainty as to the moisture content in the system, an oil sample should be

taken and tested for moisture. Sight glass/moisture indicators currently available can be used with

the HFC refrigerants and lubricants; however, the moisture indicator will just show the moisture

content of the refrigerant. The actual moisture level of POE would be higher than the sight glass

specifies. This is due to the high hygroscopicity of the POE oil. To determine the actual moisture

content of the lubricant, samples have to be taken from the system and analysed.

6.5

Oil additives

Although Emerson cannot comment on any specific product, from our own testing and past

experience, we do not recommend the use of any additives to reduce compressor bearing losses

or for any other purpose. Furthermore, the long term chemical stability of any additive in the

presence of refrigerant, low and high temperatures, and materials commonly found in refrigeration

systems is complex and difficult to evaluate without rigorously controlled chemical laboratory

testing. The use of additives without adequate testing may result in malfunction or premature

failure of components in the system and, in specific cases, in voiding the warranty on the

component.