5

2006SSD-75 R4 (10/10)

Dual-Compressor Module

Installation

2.0 i

NstallatioN

2.1 Installation Guidelines

2.1.1 Required Component—Inlet Gas Scrubber

An appropriate inlet gas scrubber is

REQUIRED

to remove liquids from the gas prior to compression. If

there is potential for liquid slugging, a suitable trap must be installed to prevent liquid from flooding and

damaging the Compressor.

NOTE

Failing to use an appropriate inlet gas scrubber to remove liquids from the gas prior to

compression can cause flooding and damage the Compressor.

2.1.2 General Installation Guidelines

Follow these general guidelines for installation:

• The Compressor Module must be installed and operated in compliance with all applicable codes and

regulations.

• The system must be installed on a level surface.

• Install pipe unions or flanges to connect the system to the inlet and discharge piping for ease of

service.

• Install isolation valves on the inlet and discharge piping.

• A common ground must be connected between the Compressor Module and the

Compressor Package chassis. This ground must comply with the National Electric Code (NEC) and

any other applicable codes.

• Solid debris also must be removed from the gas prior to compression. When required, use a 5 to 10-

micron inlet filter to remove debris from the gas stream. The degree of filtration required depends on

the specific application.

2.2 Inlet and Discharge Pressures

Refer to

Table 1

for acceptable inlet and discharge pressure levels.

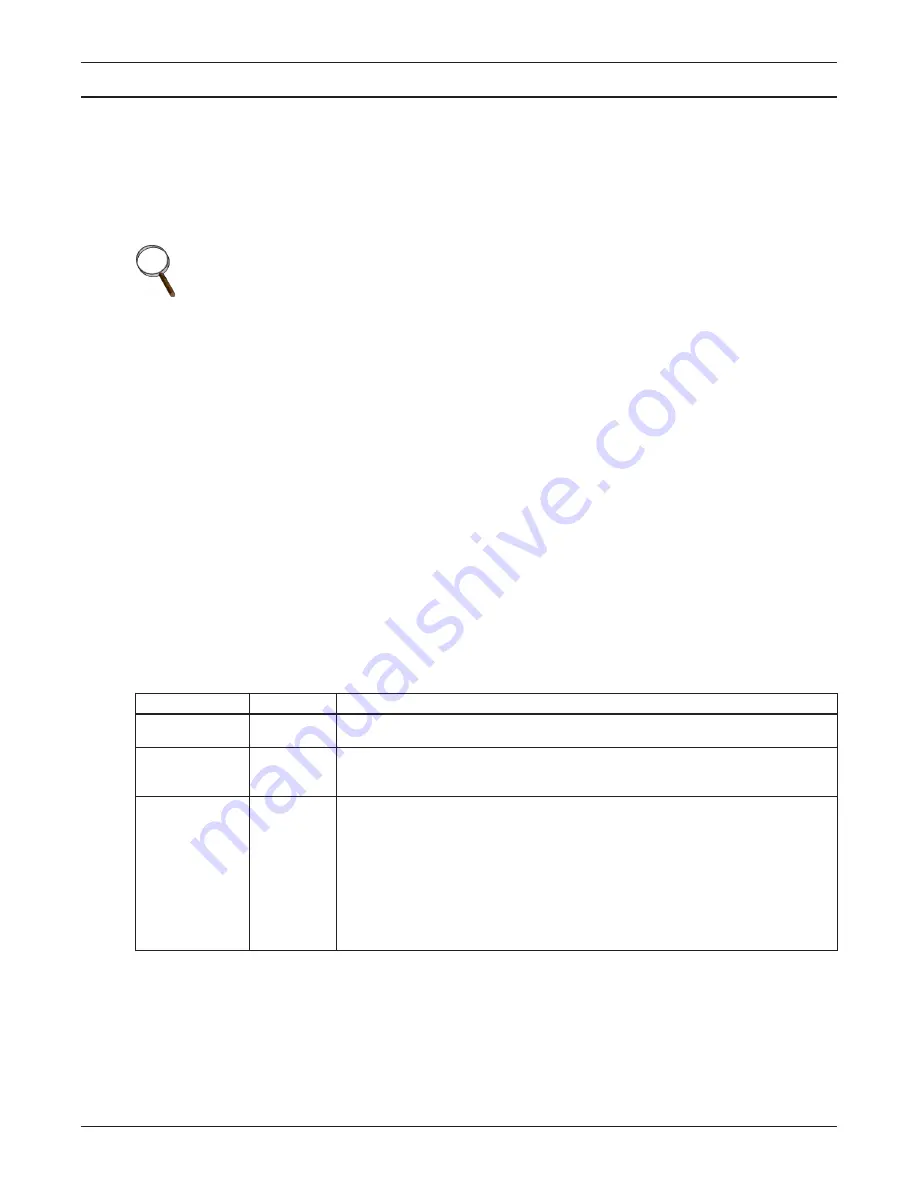

Table 1

Inlet and discharge pressure limits

Type

Level

Operating Guidelines

Minimum Inlet

Pressure

0.75 psig

Consult the factory for operations below 0.75 psig.

Maximum Inlet

Pressure

25 psig

Operation at pressures above 25 psig will result in:

• Excessive oil carryover

• Loss of oil from the Compressor Module

Discharge

Pressure

Range

70 psig

to

190 psig

(depends

on model)

When the discharge pressure of the Compressor Module reaches the maximum,

which ranges from 70 to 190 psig, depending on the model (see

Compressor

Module Nomenclature

on page

iv

):

• The Compressor Module goes into high discharge pressure recycle if

equipped.

• The Compressor Module’s bypass regulator diverts gas from the high-pressure

side to the low-pressure side of the module.

All Compressor Modules must be equipped with pressure-limiting or relief

devices. A minimum pressure differential of 70 psi between inlet and discharge

pressure is required for proper operation.

Summary of Contents for Copeland Scroll SZO44

Page 2: ......

Page 34: ...Dual Compressor Module Technical Support and Service 28 2006SSD 75 R4 10 10 ...

Page 40: ......

Page 41: ......