AGL_HP_ST_YHK1E_E_Rev02

9

3.3.1 General brazing procedure

Copeland Scroll compressors have copper-plated steel

suction and discharge stub tubes. These stub tubes are

far more robust and less prone to leaks than copper

tubes. Due to the different thermal properties of steel and

copper, brazing procedures should be carried out in an

appropriate manner.

Refer to

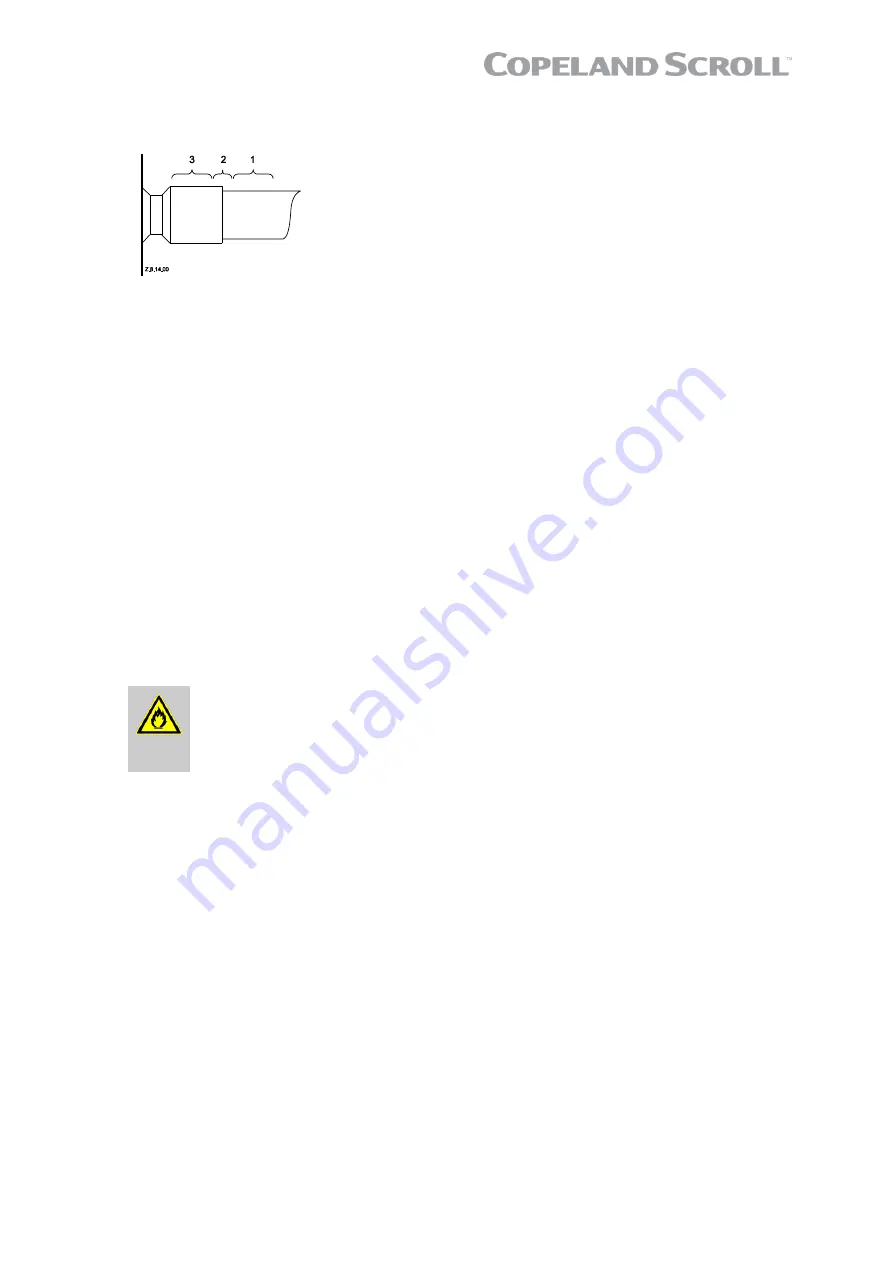

Figure 6

and procedure below for the brazing of

the stub tube connections of a scroll compressor.

▪

For systems with flammable A2L refrigerants, it is mandatory to flush oxygen-free nitrogen

through the piping during the brazing process.

▪

The copper-coated steel tubes on scroll compressors can be brazed in approximately the same

manner as any copper tube.

▪

Recommended brazing materials: any silfos material is recommended, preferably with a

minimum of 5 % silver. However, 0 % silver is acceptable.

▪

Be sure tube fitting inner diameter and tube outer diameter are clean prior to assembly.

▪

Using a double-tipped torch, apply heat in area 1.

▪

As the tube approaches brazing temperature, move the torch flame to area 2.

▪

Heat area 2 until braze temperature is attained, moving the torch up and down and rotating

around the tube as necessary to heat the tube evenly. Add braze material to the joint while

moving the torch around the joint to flow braze material around the circumference.

▪

After the braze material flows around the joint, move the torch to heat area 3. This will draw the

braze material down into the joint. The time spent heating area 3 should be minimal.

▪

As with any brazed joint, overheating may be detrimental to the final result.

NOTE: Since the discharge stub contains a check valve, care must be taken not to overheat

it to prevent brazing material from flowing into it.

3.3.2 Brazing procedure for YH*K1E compressors in parallel applications

WARNING

Air/flammable refrigerant mixture! Creation of a potentially flammable

atmosphere! Fire hazard!

Remove all refrigerant before opening the system.

When working on a refrigerant-filled system, make sure to follow the safety

and working instructions given in

Chapter 6 "Maintenance & repair"

.

Only compressor models officially approved by Emerson in the qualified configuration may be used

for parallel applications. For YH*K1E compressors in parallel applications with passive oil

management, additional precautions shall be taken before brazing the oil and gas equalization ports.

The sequence shall be as follows:

First, install the compressors on the base frame and tilt the assembly so that oil will not be lost when

opening the cap. The gas and oil equalization line assembly should be ready for brazing at this point.

For new compressors, release the protective gas charge: the rubber plug from the discharge port of

the compressor has to be removed first, then the rubber plug from the oil port.

Most probably the oil port will be coated with some oil. It is mandatory to clean out the oil before

brazing. If the inner surface is contaminated with oil the brazing material will not adhere to the surface

and the joint will fail, generating leakage. The oil should be carefully wiped out with industrial

absorption paper. Industrial solvents on a clean cloth can be used too but only with great care. Note

that emery cloth will not remove the oil.

It is possible that the oil cannot be completely cleaned out. In this case additional measures should

be taken. For instance, if a connection is coated with flux then the residual oil will be removed when

brazing due to the applied heat.

If an active oil level control is to be used, eg, Alco Controls OM* TraxOil, please refer to the product

documentation when brazing the connection adaptor.

: Brazing areas

Figure 6: Suction tube brazing areas

Summary of Contents for Copeland Scroll YH16K1E

Page 4: ...AGL_HP_ST_YHK1E_E_Rev02 9 References 33 DISCLAIMER 33 ...

Page 5: ......

Page 39: ...34 AGL_HP_ST_YHK1E_E_Rev02 ...