8

© 2014 Emerson Climate Technologies, Inc.

Printed in the U.S.A.

AE4-1317 R10

Application Engineering

B

U

L

L

E

T

I

N

brazing

fl

ame. It is important to check both the high and

low sides with manifold gauges before unbrazing. In the

case of an assembly line repair, remove the refrigerant

from both the high and low sides. Instructions should

be provided in appropriate product literatures and

assembly areas.

High Potential (Hipot) Testing

Many of the Copeland brand compressors are

con

fi

gured with the motor below the compressor. As a

result when liquid refrigerant is within the compressor

shell the motor can be immersed in liquid refrigerant to

a greater extent than with compressors with the motor

mounted above the compressor. When Copeland brand

compressors are Hipot tested and liquid refrigerant is

in the shell, they can show higher levels of leakage

current than compressors with the motor on top because

of the higher electrical conductivity of liquid refrigerant

than refrigerant vapor and oil. This phenomenon

can occur with any compressor when the motor is

immersed in refrigerant. The level of current leakage

does not present any safety issue. To lower the current

leakage reading the system should be operated for a

brief period of time to redistribute the refrigerant to

a more normal con

fi

guration and the system Hipot

tested again. See bulletin

AE4-1294

for Megohm

testing recommendations. Under no circumstances

should the Hipot or Megohm test be performed while

the compressor is under a vacuum.

Copeland Scroll

Functional Check

Refrigeration scroll compressors do not have internal

suction valves. It is not necessary to perform functional

compressor tests to check how low the compressor will

pull suction pressure. This type of test may damage a

scroll compressor. The following diagnostic procedure

should be used to evaluate whether a Copeland Scroll

compressor is functioning properly.

1. Verify proper unit voltage.

2. Normal motor winding continuity and short to

ground checks will determine if the inherent

overload motor protector has opened or if an

internal short to ground has developed. If the

protector has opened, the compressor must cool

suf

fi

ciently to reset.

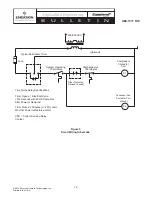

3. With service gauges connected to suction

and discharge pressure

fi

ttings, turn on the

compressor. If suction pressure falls below normal

levels, the system is either low on charge or there

is a

fl

ow blockage.

4a. Single-Phase Compressors

If the suction pressure does not drop and the

discharge pressure does not rise to normal levels

the compressor is faulty.

4b. Three-Phase Compressors

If the suction pressure does not drop and the

discharge pressure does not rise, reverse any

two of the compressor power leads and reapply

power to make sure the compressor was not wired

to run in the reverse direction.

The compressor current draw must be compared to

published compressor performance curves at the

compressor operating conditions (pressures and

voltages). Signi

fi

cant deviations (±15%) from

published

values may indicate a faulty compressor.

New Installation

• The copper-coated steel suction, discharge, and

injection tubes on scroll compressors can be

brazed in approximately the same manner as any

copper tube.

• Recommended brazing material – Any Silfos

material is recommended, preferably with a

minimum of 5% silver. However, 0% silver is

acceptable.

• Use of a dry nitrogen purge to eliminate possibility

of carbon buildup on internal tube surfaces is

recommended.

• Be sure process tube

fi

tting I.D. and process tube

O.D. are clean prior to assembly.

• Apply heat in Area 1. As tube approaches brazing

temperature, move torch

fl

ame to Area 2.

• Heat Area 2 until braze temperature is attained,

moving torch up and down and rotating around

tube as necessary to heat tube evenly. Add braze

material to the joint while moving torch around

circumference.

• After braze material

fl

ows around joint, move torch

to heat Area 3. This will draw the braze material

down into the joint. The time spent heating Area 3

should be minimal.

• As with any brazed joint, overheating may be

detrimental to the

fi

nal result.