9

© 2014 Emerson Climate Technologies, Inc.

Printed in the U.S.A.

AE4-1317 R10

Application Engineering

B

U

L

L

E

T

I

N

Field Service

To disconnect:

• Recover refrigerant from both the high and low

side of the system. Cut tubing near compressor.

To reconnect:

• Recommended brazing materials – Silfos with

minimum 5% silver or silver braze material with

fl

ux.

• Reinsert

tubing

fi

tting.

• Heat tube uniformly in Area 1, moving slowly to

Area 2. When joint reaches brazing temperature,

apply brazing material.

• Heat joint uniformly around the circumference to

fl

ow braze material completely around the joint.

• Slowly move torch in Area 3 to draw braze material

into the joint.

Do not overheat joint.

}

}

}

1

2

3

Scroll Tube Brazing

Figure 1A

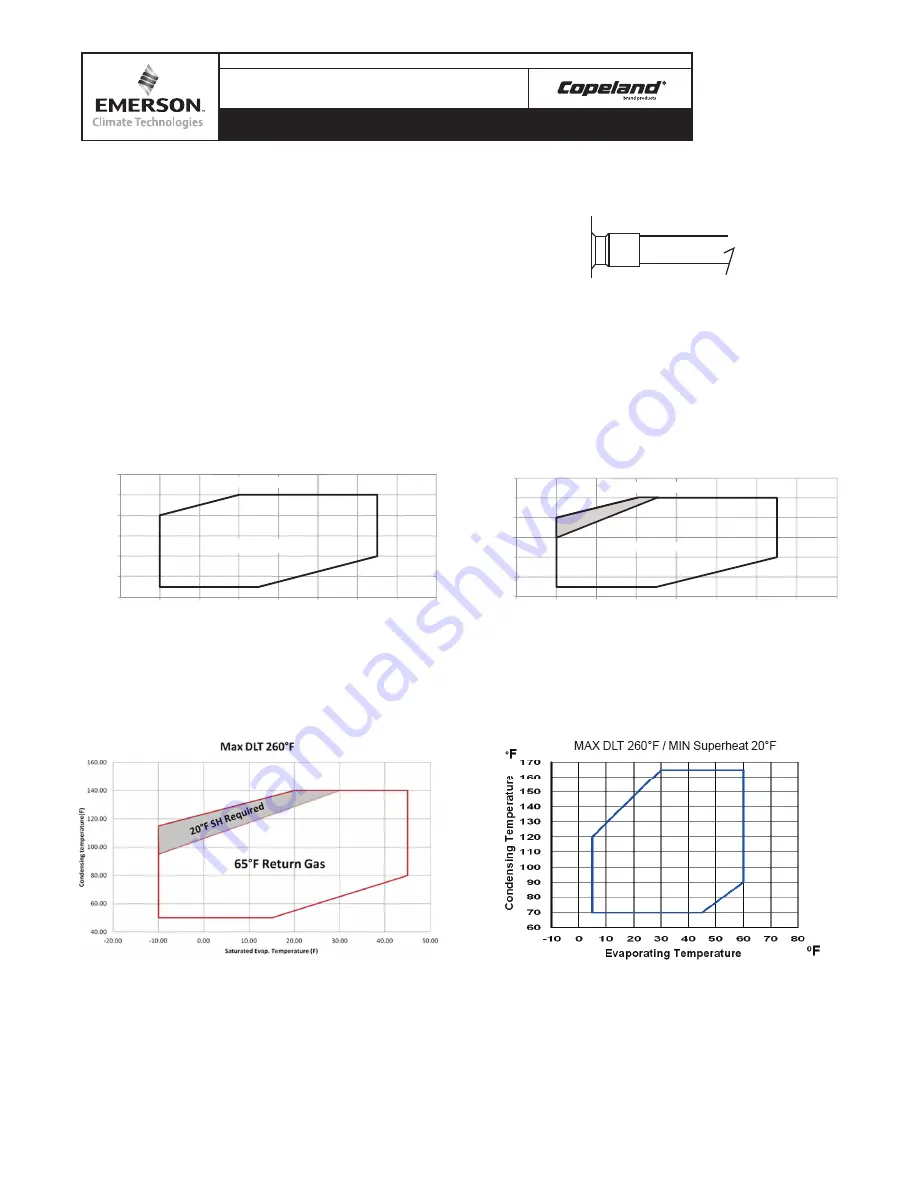

ZB*KCE Application Envelope for

R-404A / R-507 (1.3 - 7.5 HP)

p

-10

50

-10

120

10

140

45

140

45

80

15

50

-10

50

-10

120

10

140

15

140

-10

100

-10

120

40

60

80

100

120

140

160

-20

-10

0

10

20

30

40

50

60

Condensi

ng T

e

mperat

ure (

°F)

Evaporating Temperature ( °F)

65°F Return Gas

MAX DLT 260°F

Figure 1D

ZB*KCE Application Envelope for

134a 2-7.5 HP

Figure 1B

ZB*KCE Application Envelope for

R-407A / R-407C (1.3 - 7.5 HP)

40

60

80

100

120

140

160

-20

-10

0

10

20

30

40

50

Condensi

ng T

e

mperat

ure (

°F)

Evaporating Temperature ( °F)

20F SH Required

65°F Return Gas

MAX DLT 260°F

Figure 1C

ZB*KCE Application Envelope for

R-407F (1.3 - 7.5 HP)