C6.2.26/1013-1116/E

11

orifice from plugging with system debris. Tests have shown that a small screen with a fine mesh

can easily become plugged causing oil starvation to the compressor bearings.

The size of the accumulator depends upon the operating range of the system and the amount of

subcooling and subsequent head pressure allowed by the refrigerant control. System modelling

indicates that heat pumps that operate down to and below -18°C will require an accumulator that

can hold around 70% to 75% of the system charge.

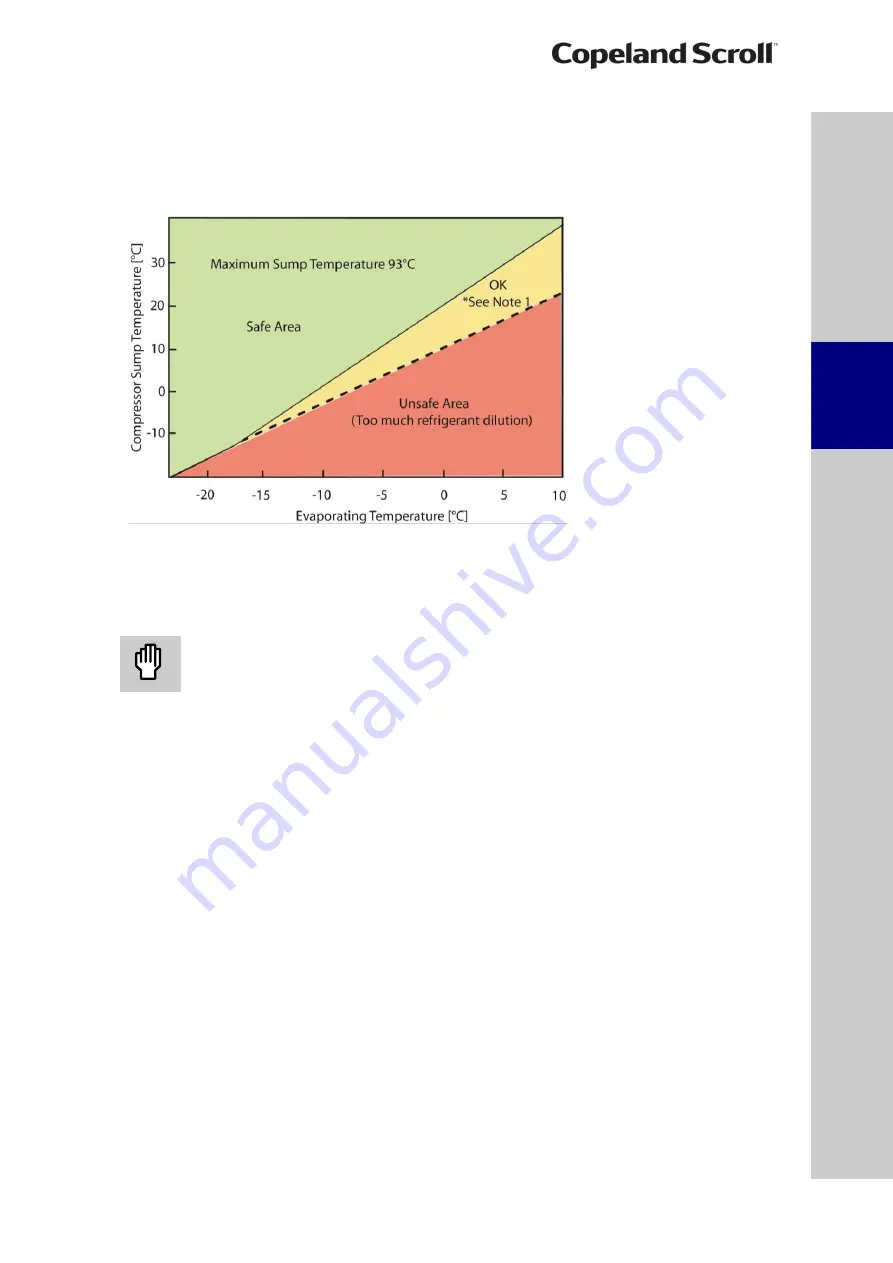

Figure 6: Dilution chart for transient operation (tb = bottom shell temperature; te = evaporating temperature)

Note 1: Low load operation may be acceptable in the yellow marked area. Please contact

the Application Engineering department at Emerson Climate Technologies.

3.4 Screens

CAUTION

Screen blocking! Compressor breakdown!

Use screens with at least

0.6 mm openings.

The use of screens finer than 30 x 30 mesh (0.6 mm openings) anywhere in the system should

be avoided with these compressors. Field experience has shown that finer mesh screens used

to protect thermal expansion valves, capillary tubes or accumulators can become temporarily or

permanently plugged with normal system debris and block the flow of either oil or refrigerant to

the compressor. Such blockage can result in compressor failure.

3.5 Mufflers

External mufflers, normally applied to piston compressors in the past, may not be required for

Copeland Scroll compressors.

Individual system tests should be performed to verify acceptability of sound performance. If

adequate attenuation is not achieved, use a muffler with a larger cross-sectional area to inlet

area ratio. A ratio of 20:1 to 30:1 is recommended.

A hollow shell muffler will work quite well. Locate the muffler at minimum 15 to maximum 45 cm

from the compressor for the most effective operation. The farther the muffler is placed from the

compressor within these ranges, the more effective. Choose a muffler with a length of 10 to

15 cm.

3.6 Reversing valves

Since Copeland Scroll compressors have a very high volumetric efficiency their displacements

are lower than those of equivalent capacity reciprocating compressors. As a result, Emerson

Climate Technologies recommends that the capacity rating on reversing valves be no more than

1.5 to 2 times the nominal capacity of the compressor in order to ensure proper operation of the

reversing valve under all operating conditions.

The reversing valve solenoid should be wired so that the valve does not reverse when the

system is shut off by the operating thermostat in the heating or cooling mode. If the valve is

allowed to reverse at system shut off, suction and discharge pressures are reversed to the

S

afet

y

inst

ru

ctio

n

s

P

ro

d

u

ct

d

es

cr

ipt

ion

Inst

all

atio

n

E

lec

tr

ica

l

c

o

n

n

ec

tion

S

tar

ting

up

&

o

p

er

atio

n

Ma

int

enan

c

e

&

repai

r

T

ro

u

b

le

-

sho

o

ting

Dismant

ling

&

d

ispo

sa

l

Ref

er

en

ce

s