12

C6.2.26/1013-1116/E

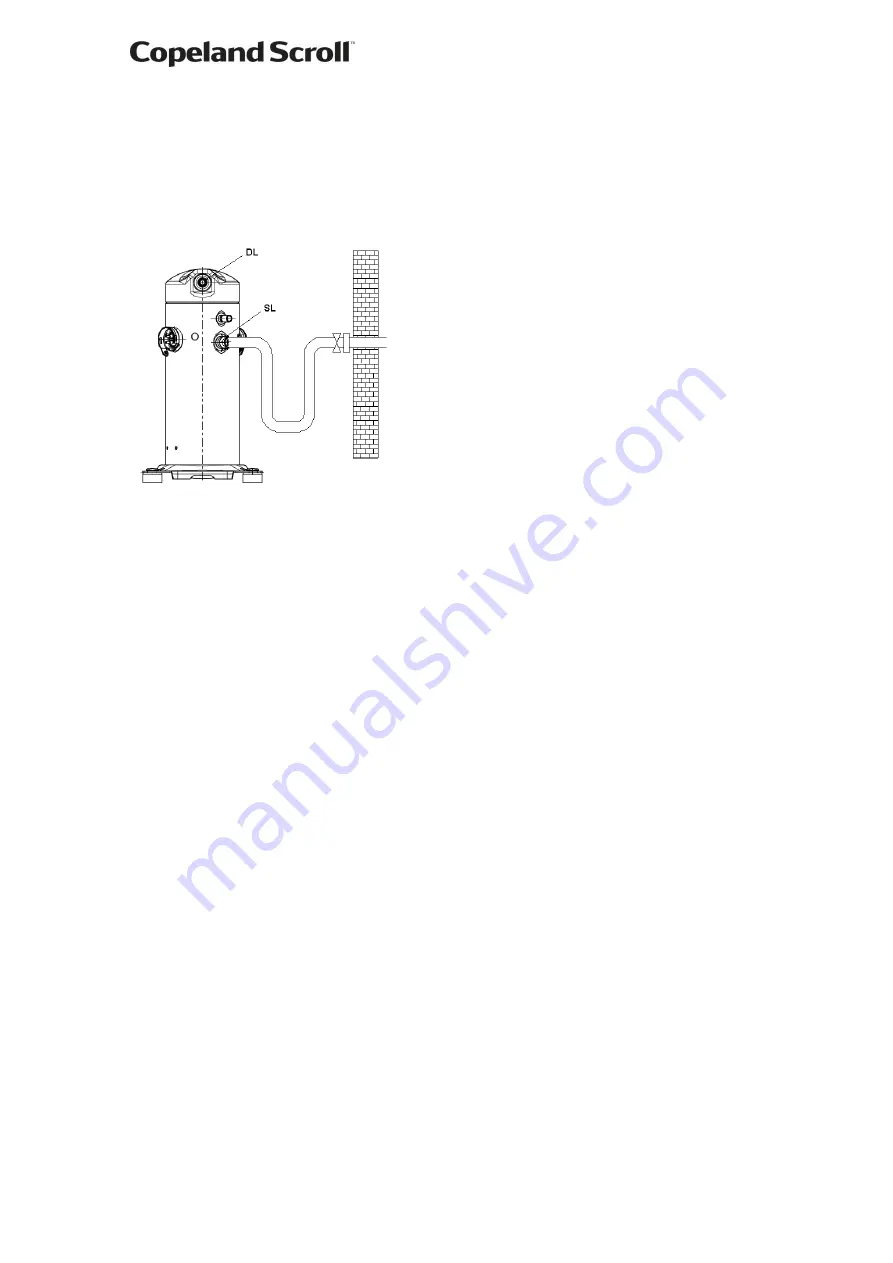

Figure 7: Suction tube design

compressor. This results in a condition of system pressures equalising through the compressor

which can cause the compressor to slowly rotate until the pressures equalise. This condition

does not affect compressor durability but can cause unexpected sound after the compressor is

turned off.

3.7 Suction line noise and vibration

Proper pipe design must be taken into consideration when connecting a scroll compressor to the

system.

A scroll compressor makes both a rocking and

twisting motion and enough flexibility must be

provided in the pipe-lines to allow starting, stopping

and steady state running of the compressor without

transmitting excessive stress into any line attached

to the unit. In a split system, the most important

goal is to ensure minimal vibration in all directions

to avoid transmitting vibrations to the structure to

which the lines are fastened.

Under some conditions, the Copeland Scroll has a

normal starting rotational motion that can transmit

a transient noise along the lines. This may be

particularly pronounced in compressors using a

three-phase motor due to their inherently higher

starting torque. This phenomenon, like the one

described previously, can easily be avoided by

using standard line isolation techniques.

The sound level of a system is the result of design, quality and application. Scroll compressors

sound power levels generally increase with the compressor model capacity and the condition

pressure ratio.