C6.2.26/1013-1116/E

17

The motor insulation material is class "B" (PF* and T

F

*) or "H" (T

W

*) for compressor models

covered in these guidelines.

4.2.4 Protection devices

Independently from the internal motor protection, fuses must be installed before the compressor.

The selection of fuses has to be carried out according to VDE 0635, DIN 57635, IEC 269-1 or

EN 60-269-1.

4.2.5 Crankcase heaters

IMPORTANT

Oil dilution! Bearing malfunction!

Turn the crankcase heater on 12 hours

before starting the compressor.

A crankcase heater is required when the system charge exceeds the compressor charge limit,

listed in

Table 3

.

Compressor model

Refrigerant charge limit

Single compressor

systems

Refrigerant charge limit

Even Tandem systems

ZH04K1P & ZH05K1P

3.6 kg

5.0 kg

ZH06K1P to ZH12K1P

ZHI05K1P to ZHI14K1P

4.5 kg

6.3 kg

ZH15K1P & ZH19K1P

ZHI18K1P & ZHI23K1P

4.5 kg

6.3 kg

ZHI27K1P to ZHI46K1P

7 kg

10.9 kg

Table 3

:

Refrigerant charge limit

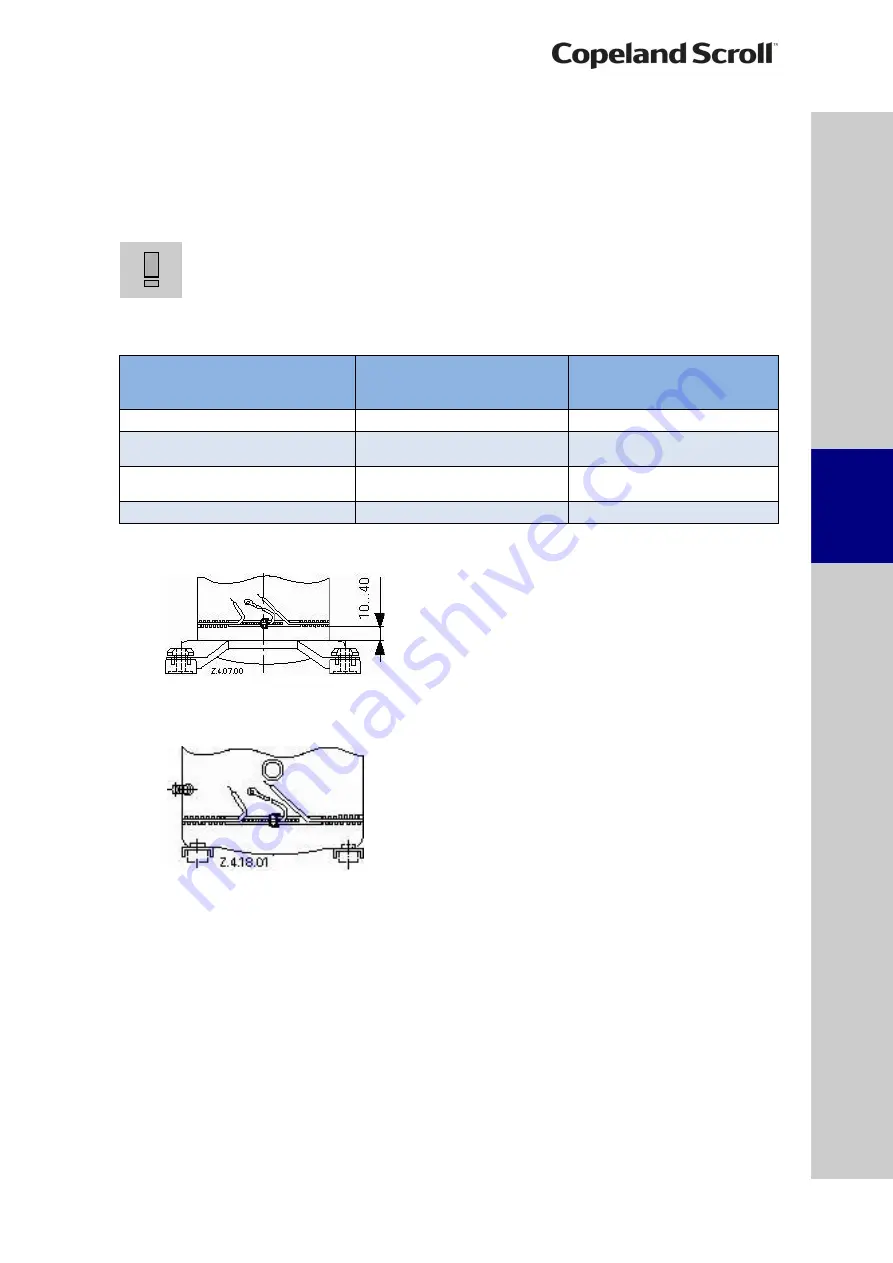

For compressor models

ZH04K1P to ZH19K1P

and ZHI05K1P to ZHI23K1P, the crankcase

heater must be mounted 10 to 40 mm above

compressor legs (see

Figure 14

).

Figure 14: Crankcase heater location, models ZH04K1P to ZH19K1P and ZHI05K1P to ZHI23K1P

For

compressor

models

ZHI27K1P

to

ZHI46K1P, the crankcase heater must be

mounted below the oil removal valve located on

the bottom shell for tandem versions (see

Figure 15

).

Figure 15: Crankcase heater location, models ZHI27K1P to ZHI46K1P

NOTE: The crankcase heater must be turned on a minimum of 12 hours prior to starting

the compressor and must remain energised during compressor off cycles.

4.2.6 Soft starters

Soft starters can be used with the 20 to 40 hp Copeland Scroll compressors to reduce inrush

current. Soft starters should be selected in accordance with the soft starter manufacturer's

recommendations, taking into consideration ambient temperature, number of starts per hour, and

compressor amps. The maximum ramp-up time should not exceed 3 seconds.

S

afet

y

inst

ru

ctio

n

s

P

ro

d

u

ct

d

es

cr

ipt

ion

Inst

all

atio

n

E

lec

tr

ica

l

con

n

ec

tion

S

tar

ting

up

&

o

p

er

atio

n

Ma

int

enan

c

e

&

repai

r

T

ro

u

b

le

-

sho

o

ting

Dismant

ling

&

d

ispo

sa

l

Ref

er

en

ce

s