6 Lubrication

The compressor is supplied with an initial charge of polyolester (POE) lubricant. In the field the oil level could be

topped up with Mobil EAL Arctic 22 CC. The recharge values can be taken from Copeland Selection Software.

Although there is no flexible mounting of the internal compressor parts, the number of start/stop cycles should be

limited to 10 per hour. A high cycling rate will pump oil into the system and may lead to lubrication failure. Oil leaves

the compressor at start-up regardless of the low oil carry over of the Copeland Scroll. The short running time is

insufficient to return the oil to the compressor and possibly results in a lack of lubricant.

It must be considered that the entire system will be coated with oil to some extent. Oil viscosity changes with

temperature. System gas velocity changes depending on temperature and load. In low load conditions gas velocity

may not be high enough to return oil to the compressor. System piping should be designed to return oil under all

operating conditions.

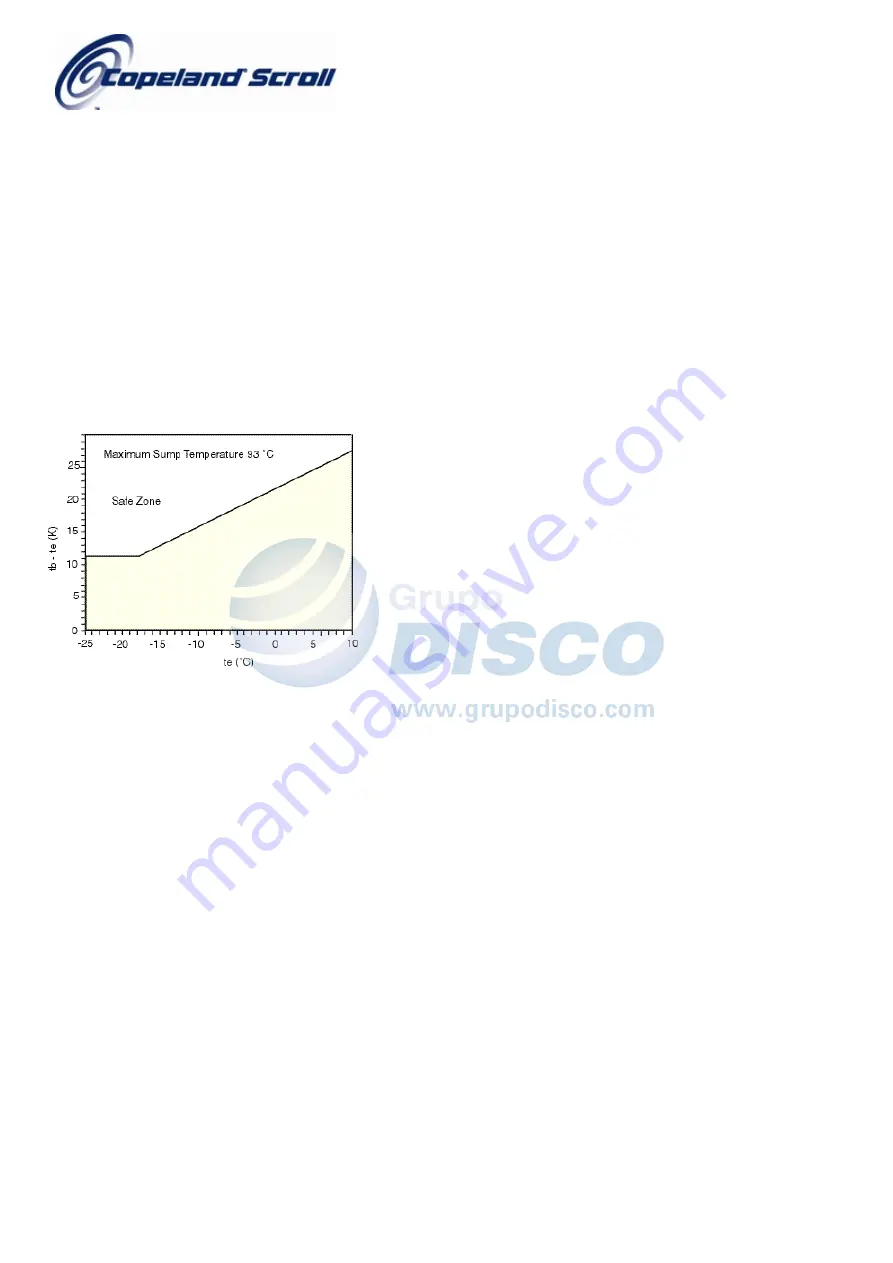

For proper lubrication the minimum differential between bottom shell

(tb) and evaporating (te) temperatures should be carefully observed

as laid out in Figure 2. On the other hand, the maximum bottom shell

temperature should never exceed 93°C, measured close to the bottom

center of the compressor.

Figure 2: Minimum bottom shell temperature (tb)

One characteristic of POE is that it is far more hygroscopic than mineral oil (Figure 3). Only brief exposure to ambient

air is needed for POE to absorb sufficient moisture to make it unacceptable for use in a refrigeration system. Since

POE retains moisture chemically it is not possible to completely remove it through the use of vacuum.

Compressors supplied by Copeland contain oil with a low moisture content, and this may rise during the system

assembling process. Therefore it is recommended that a properly sized filter-drier is installed in all POE systems. This

will maintain the moisture level in the oil to less than 50 ppm. If oil is charged into a system it is recommended to

charge systems with POE containing no more than 50 ppm moisture content. If the moisture content of the oil in a

refrigeration system reaches unacceptable high levels, corrosion and copper plating may occur.

The system should be evacuated down to 0.3 mbar or lower. If there is uncertainty, as to the moisture content in the

system, an oil sample should be taken and tested for moisture. Sight glass/moisture indicators currently available can

be used with the HFC refrigerants and lubricants; however, the moisture indicator will just show the moisture contents

of the refrigerant. The actual moisture level of POE would be higher than the sight glass specifies. This is a result of

the high hygroscopicity of the POE oil. Oil samples would have to be taken from the system and analyzed to

determine the actual moisture content of the lubricant.

C6.2.16/1004/E 4